So. Loaded up my first handloads ever in 6.5 creedmoor. I had some ejector/bolt swipes way faster than I thought.

Springfield Waypoint with 22" carbon barrel.

New Starline srp.

Sinclair Mandrel .262

Chamfer and debured.

Did not full size.

I had previously measured my chamber Using the loctite method.

CBTL- 2.2635 - .0350 off lands= 2.2285 CBTO.

I'm limited by AICS magazine length. I'm told max is 2.84".

My COAL is about 2.81 with that bullet at that CBTO. COAL seems to vary though.

H4350

Hornady 140gr BTHP

Cci 450s

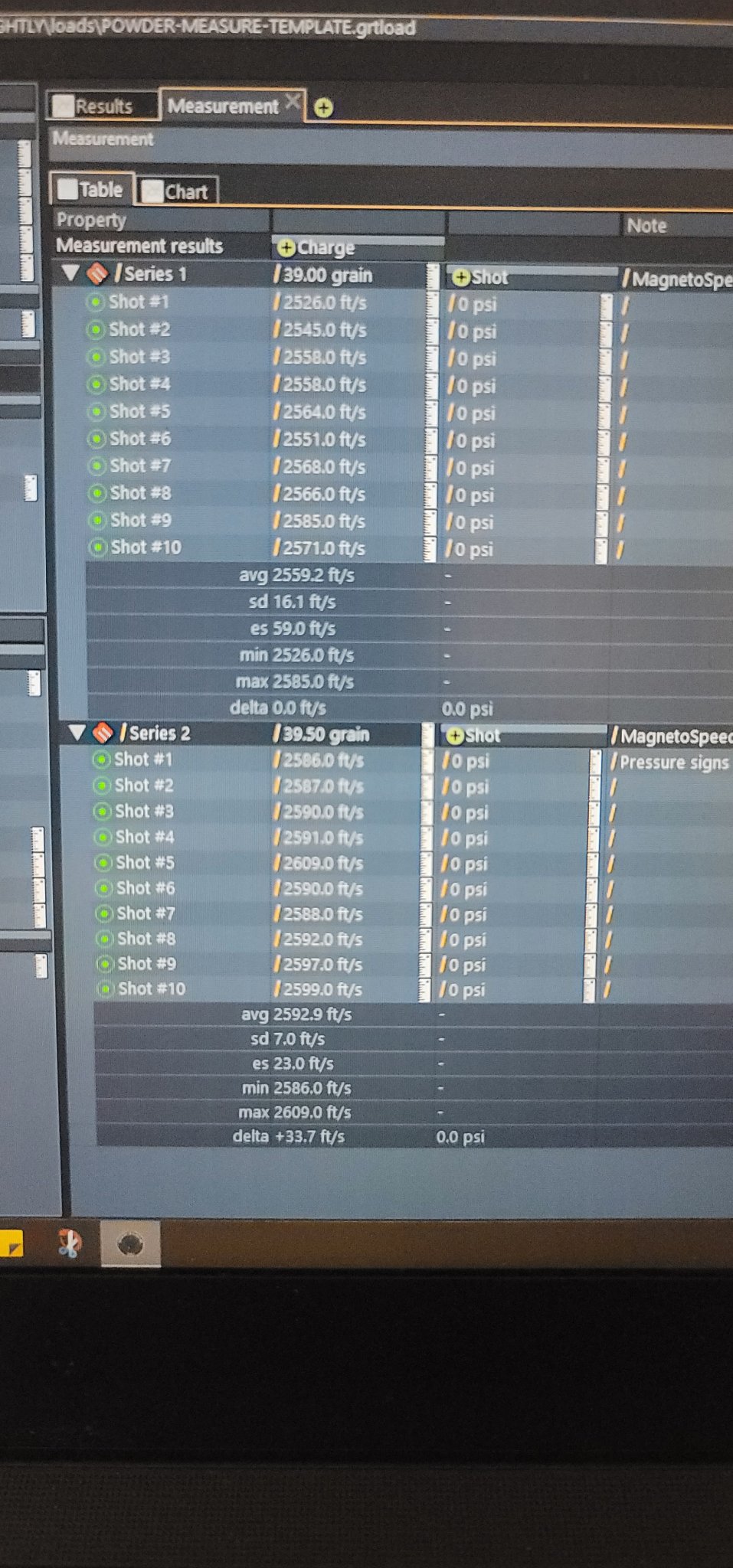

Hornadys max says 41.5. So I started at 39 and went up to 41 by .5 grains increments.

39 grains I wasn't seeing any signs.

Once i got to 39.5 I was seeing bolt swipes. I was very surprised to see pressure signs with my velocities being under 2600fps so soon

Here's my magnetospeed results.

Do I need to back off the lands further?

Springfield Waypoint with 22" carbon barrel.

New Starline srp.

Sinclair Mandrel .262

Chamfer and debured.

Did not full size.

I had previously measured my chamber Using the loctite method.

CBTL- 2.2635 - .0350 off lands= 2.2285 CBTO.

I'm limited by AICS magazine length. I'm told max is 2.84".

My COAL is about 2.81 with that bullet at that CBTO. COAL seems to vary though.

H4350

Hornady 140gr BTHP

Cci 450s

Hornadys max says 41.5. So I started at 39 and went up to 41 by .5 grains increments.

39 grains I wasn't seeing any signs.

Once i got to 39.5 I was seeing bolt swipes. I was very surprised to see pressure signs with my velocities being under 2600fps so soon

Here's my magnetospeed results.

Do I need to back off the lands further?

Attachments

Last edited: