Gotta show off the new galvenized peg board somehow.

CR Mod-O on a tuned up Remmy.

Work performed:

Our new DBM installed.

CR Mod-O on a tuned up Remmy.

Work performed:

- Single stroke diamond honed receiver bore

- Tier 1 blueprinted on our 5 axis cnc mill

- Pinned lug

- Blueprinted bolt on one of our 4 axis vertical cnc mills

- Tig welded tang groove (std thing when we are stocking the gun)

- M40 clip slotted

- M40 double radius ejection port

- Side bolt release

- M16 xtr install on bolt with dual ejectors

- 8-40 base hole upgrade

- Timed/Tig'd handle with timing advance

- Faceted bolt shroud

- Bolt fluting

- Tac knob install

- Barrel fitted, 6.5mm Creedmoor for ELDX 140's

- Muzzle threading

- Thread protector installation

- cnc stock inletting

- Pillar bedding

- All hardware installation

- Cross pinned trigger/mag box web

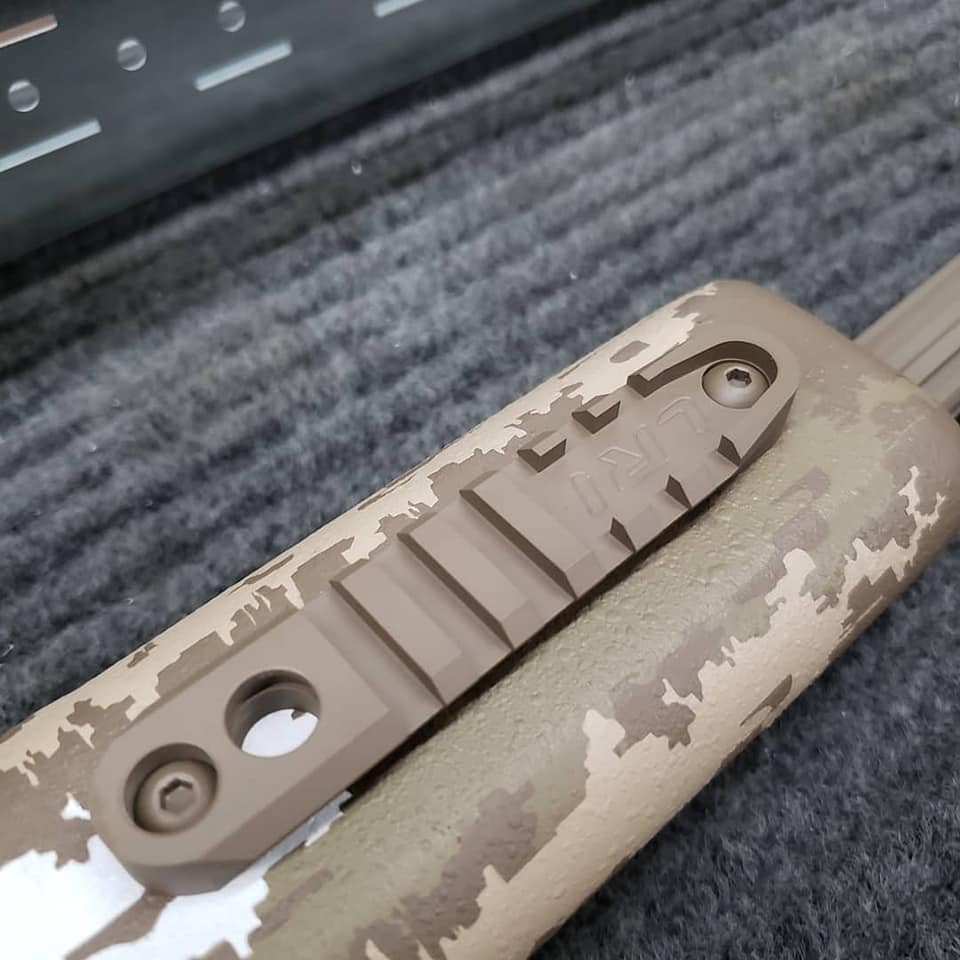

- Camo Stencil cutting

- All finishing/coating work

- M700 SS SA

- LRI Lug

- LRI bipod mount

- LRI Side bolt release

- LRI M16 xtr

- LRI 20moa M40 type lugged base

- LRI HD flush cup

- LRI HTR DBM

- LRI ULTACH hardware

- Manners T5A

- K&P barrel blank

- Jewel trigger

Our new DBM installed.

Last edited: