A friend of mine has a Mauser bolt that he wants to clean up the face and open it up to a magnum. He cleaned the face with a carbide bar, but when he tried to open it up he said it would just whine and chatter. He has asked me to try on my lathe, but I have never opened one up before. Any suggestions? If my carbide boring bar doesn't work, I have a tool holder for a dremmel tool. That plus a lot of coolant should work?

Gunsmithing Mauser Bolt Face Question

- Thread starter GB213

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re: Mauser Bolt Face Question

Some of these bolts are pretty hard. I would recommend that the bolt face be annealed.

Some of these bolts are pretty hard. I would recommend that the bolt face be annealed.

Re: Mauser Bolt Face Question

Brunell makes a carbide cutter just made for openning up bolt faces on harden bolts. I've done several mausers. Make sure everything is tight and lined up.

I'm casting my vote NOT to annel the bolt face.

Brunell makes a carbide cutter just made for openning up bolt faces on harden bolts. I've done several mausers. Make sure everything is tight and lined up.

I'm casting my vote NOT to annel the bolt face.

Re: Mauser Bolt Face Question

A side note I recall a Hinnant remark about some old Mauser actions being case hardened.

A side note I recall a Hinnant remark about some old Mauser actions being case hardened.

Re: Mauser Bolt Face Question

Do you have the ability to Rockwell it?

Interesting thought though. I may Rockwell my Mauser bolt tomorrow for the fun of it.

Do you have the ability to Rockwell it?

Interesting thought though. I may Rockwell my Mauser bolt tomorrow for the fun of it.

Re: Mauser Bolt Face Question

you may find that the bolts are case hardened as many were. It was a simple method of hardening used for quite some time in the manufacture of the mauser rifles. It was cheap and effective. Many of the Mauser rifle guides for modification recommend that the bolt faces not be cut too deeply as the hardening will be cut through. Rockwell testing a case hardened part will not always get you a proper number due to the softer inside material giving way so figuring out whether its case or through hardened will not be simple without destructive testing.

Having said all that, a good carbide tool will cut the case hardened bolt face without problems if you insure that the bolt is well supported and the tool as well. Keep the overhang on the tool in your toolholder as short as possible so it won't spring.

Frank

you may find that the bolts are case hardened as many were. It was a simple method of hardening used for quite some time in the manufacture of the mauser rifles. It was cheap and effective. Many of the Mauser rifle guides for modification recommend that the bolt faces not be cut too deeply as the hardening will be cut through. Rockwell testing a case hardened part will not always get you a proper number due to the softer inside material giving way so figuring out whether its case or through hardened will not be simple without destructive testing.

Having said all that, a good carbide tool will cut the case hardened bolt face without problems if you insure that the bolt is well supported and the tool as well. Keep the overhang on the tool in your toolholder as short as possible so it won't spring.

Frank

Re: Mauser Bolt Face Question

Do not use a dremel. If you do use a bolt facing tool make sure you check the firing pin extrusion and adjust. I am with using the Brownells facing tool and not anealing anything on the bolt.

Do not use a dremel. If you do use a bolt facing tool make sure you check the firing pin extrusion and adjust. I am with using the Brownells facing tool and not anealing anything on the bolt.

Re: Mauser Bolt Face Question

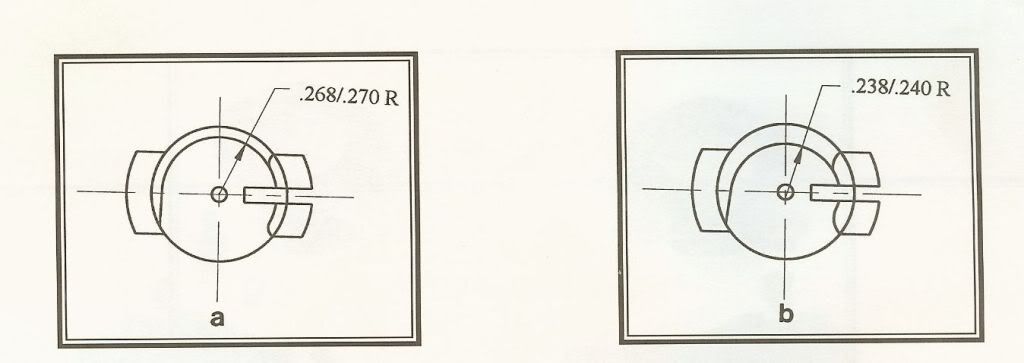

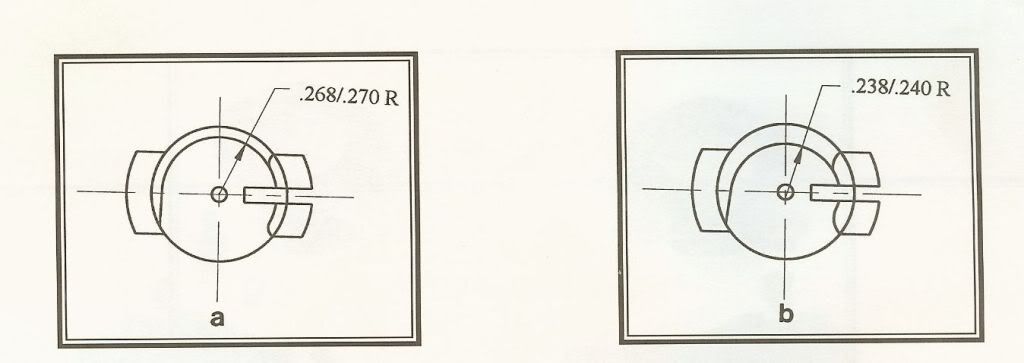

The bolt on the left is magnum, the one on the right is non-magnum.

http://www.amazon.com/Mauser-M98-M96-Ronald-Walsh/dp/187935652X

Walsh's book has great, I mean great instructions on the feed lip and ramp mod for Magnums.

Walsh defines the change the magazine length.

Walsh shows some on the bolt face change.

I can see nothing on the extractor change in that book.

It is out of print. I can't help but feel that Walsh, a chief engineer, wrote that book as a labor of love and out of the frustration of trying to read the Kuhnhausen book on sporterizing Mausers. The Kuhnhausen book is still in print. Life ain't fair.

Video on youtube of Mauser bolt face being opened for magnum on the lathe

The bolt on the left is magnum, the one on the right is non-magnum.

http://www.amazon.com/Mauser-M98-M96-Ronald-Walsh/dp/187935652X

Walsh's book has great, I mean great instructions on the feed lip and ramp mod for Magnums.

Walsh defines the change the magazine length.

Walsh shows some on the bolt face change.

I can see nothing on the extractor change in that book.

It is out of print. I can't help but feel that Walsh, a chief engineer, wrote that book as a labor of love and out of the frustration of trying to read the Kuhnhausen book on sporterizing Mausers. The Kuhnhausen book is still in print. Life ain't fair.

Video on youtube of Mauser bolt face being opened for magnum on the lathe

Re: Mauser Bolt Face Question

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: pinzmann</div><div class="ubbcode-body">Some of these bolts are pretty hard. I would recommend that the bolt face be annealed. </div></div>

Then it would have to be re-hardened, and not knowing the composition of the steel since there were so many Mausers made so many places for 50 or more years, it would be a crap shoot whether the re-hardened bolt would stand up to a magnum, whether it would be too brittle, too soft, etc.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: pinzmann</div><div class="ubbcode-body">Some of these bolts are pretty hard. I would recommend that the bolt face be annealed. </div></div>

Then it would have to be re-hardened, and not knowing the composition of the steel since there were so many Mausers made so many places for 50 or more years, it would be a crap shoot whether the re-hardened bolt would stand up to a magnum, whether it would be too brittle, too soft, etc.

Re: Mauser Bolt Face Question

The real problem with annealing a bolt and then rehardening is that anytime you heat metal up beyond its critical point it is likely to warp. Rehardening the bolt means you might end up with a pretzel or maybe just something that won't quite fit back in the receiver. Not a good idea to anneal. Just use the right tools for the job.

Frank

The real problem with annealing a bolt and then rehardening is that anytime you heat metal up beyond its critical point it is likely to warp. Rehardening the bolt means you might end up with a pretzel or maybe just something that won't quite fit back in the receiver. Not a good idea to anneal. Just use the right tools for the job.

Frank

Re: Mauser Bolt Face Question

GB213,

If the bolt was not treated from the factory, steel can work harden overtime when subjected to heat & abuse. Example: try drilling stainless steel with too fast rpm, not enough feed and coolant. You'll quickly find out what work hardened is...

With that, in my short years of cutting hardened steel (sometimes intentionally), the key is in the feeds, speeds, tooling sharpness, and solid set-up. Try cutting at a slower speed with small steps. Also as previous stated keep your set-up ridged. If rpm's are too high, you will quickly wear out your tool (sounds like it already happened). Remember, keep the heat in the chip not in the tooling.

Hope this helps,

Jason

GB213,

If the bolt was not treated from the factory, steel can work harden overtime when subjected to heat & abuse. Example: try drilling stainless steel with too fast rpm, not enough feed and coolant. You'll quickly find out what work hardened is...

With that, in my short years of cutting hardened steel (sometimes intentionally), the key is in the feeds, speeds, tooling sharpness, and solid set-up. Try cutting at a slower speed with small steps. Also as previous stated keep your set-up ridged. If rpm's are too high, you will quickly wear out your tool (sounds like it already happened). Remember, keep the heat in the chip not in the tooling.

Hope this helps,

Jason

Re: Mauser Bolt Face Question

When they are hard, I cut them with carbide.

Carbide does not like the interrupted cuts, which this is.

Sometimes I turn the mill by hand.

Once they are welded up with soft steel, then they are easy to cut.

I was shooting this one today.

It takes a heavy load to get 7mmRemMag to have loose primer pockets in one shot.

When they are hard, I cut them with carbide.

Carbide does not like the interrupted cuts, which this is.

Sometimes I turn the mill by hand.

Once they are welded up with soft steel, then they are easy to cut.

I was shooting this one today.

It takes a heavy load to get 7mmRemMag to have loose primer pockets in one shot.

Similar threads

- Replies

- 3

- Views

- 209