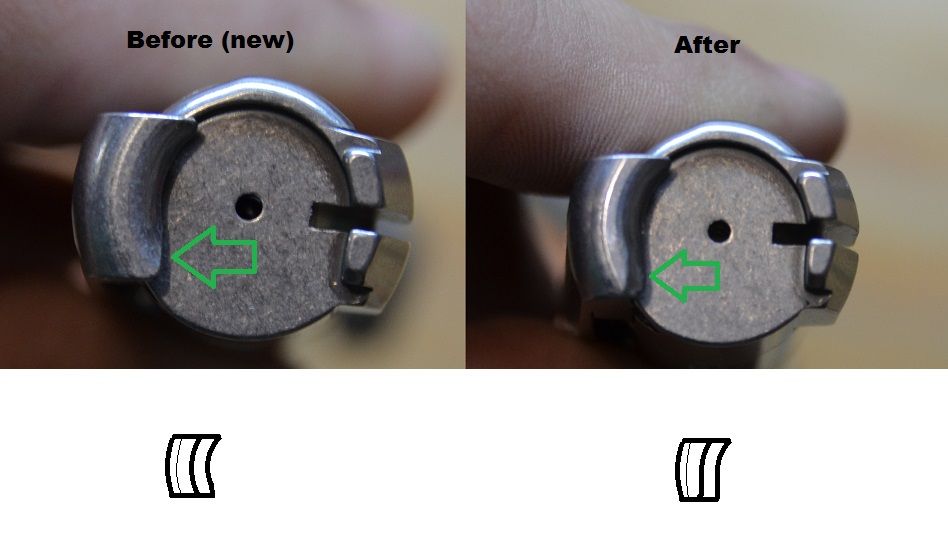

Im not happy with the way my M5 feeds. The problem is that the rounds don't snap up into the claw extractor without an excessive force being applied to the bolt. The only way to get a round to feed into the chamber is to run the bolt at 100 mph. I do run it hard most of the time, but it's definitely not smooth.

In the attached video, you can see the round pop out of the magazine as the bolt moves forward. I was hoping that it would pop all the way into the claw extractor, but you can see that the round is still held below the bolt face, and it is not controlled by the extractor. I then push the bolt forward and it hits a hard stop where the round is jammed with a sharp upwards pointing angle. In the video, when the bolt stops moving forward, it's because it won't go any farther. I suppose I might be able to jam it home at that point but not without putting way more force on it than I want.

As anyone else having this issue? Is there a way to adjust the claw extractor to make it easier for the round to pop onto the bolt face?

I'd appreciate any thoughts or advice.

In the attached video, you can see the round pop out of the magazine as the bolt moves forward. I was hoping that it would pop all the way into the claw extractor, but you can see that the round is still held below the bolt face, and it is not controlled by the extractor. I then push the bolt forward and it hits a hard stop where the round is jammed with a sharp upwards pointing angle. In the video, when the bolt stops moving forward, it's because it won't go any farther. I suppose I might be able to jam it home at that point but not without putting way more force on it than I want.

As anyone else having this issue? Is there a way to adjust the claw extractor to make it easier for the round to pop onto the bolt face?

I'd appreciate any thoughts or advice.