I have a new 6.5 CM MPA build (planning to talk with them tomorrow) that is misfiring on 1/3 of my handloads. These are loads that have never misfired in my Bergara. They consist of Lapua brass, fired 3-4X, fully resized .005 shorter on headspace than post firing and within spec. Case length is 1.92 in. Primers are CCI 450. I have tried a new box of primers from a different lot without benefit. Each round is hand primed and primers well seated. The misfire cartridges show what looks like an adequate pin strike indentation. Powder is 41.5 gr of RL 16 and bullets are Berger 130 hybrids. COAL is 2.825. I have fired factory Hornady 140 gr Match ammo with no misfires. The factory ammo uses a large rifle primer, whereas the Lapua brass uses a small rifle primer. The action is a Curtis Custom Axiom. I have picked up a box of Federal small rifle primers and plan to try that, and have some Hornady brass I can load and try, but would appreciate any suggestions or insights. Thanks in advance.

Gunsmithing Misfire Diagnosis Help Needed

- Thread starter pbatesaz

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I wouldn't worry about the small primer as a culprit for ignition problems. I had read about that in the past and when I switched to Lapua 308 Palma brass I attempted to duplicate any missfires ranging from single digit temps all the way through 105°. Those were actual temps ammo had been temporarily stored in to reflect actual shooting temps not put on ice or artificially heated. Using CCI 450 primers and a full case of AR-COMP or Varget I never had any hangfires or failures to fire.

A more likely cause in your case is a short list.

1) Excessive headspace on sized brass

2) Primers not fully seated

3) Contaminated or improperly stored primers

4) Cleaning media stuck in flash holes

5) Bad batch of primers

A more likely cause in your case is a short list.

1) Excessive headspace on sized brass

2) Primers not fully seated

3) Contaminated or improperly stored primers

4) Cleaning media stuck in flash holes

5) Bad batch of primers

Did you try firing the "duds" in your Bergara?

1) dirt crap or grease inside bolt retarding fall of the pin

2) FP spring not strong enough

2) FP spring not strong enough

1) dirt crap or grease inside bolt retarding fall of the pin

2) FP spring not strong enough

I thought initially of something similar but he stated that the factory rounds have been 100% reliable.

I guess you really can't rule anything out sight unseen though.

Missed that.

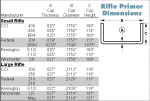

The 450 primers are thicker than 400's wonder about the factory stuff.

Still a small chunk could put you on that edge and with .005 bump could add up?

The CCI450 primers are still thinner than large rifle but the difference in pretty miniscule. Having .005" headspace maybe more since we haven't actually verified that, not doubting the OP but have seen stranger things.

Attachments

Ok so I am also parinoid.

About saying handload to the factory.

Also the reloads fired in a different chamber or the new gun.

Hmmmm?

The best I can figure without more details is he is using brass that has been fired 3-4 times in a different rifle since he states the rifle in question is new.

He also stated no issues with factory ammo in new rifle so I think he needs to measure the base to shoulder dimensions of the factory ammo he's using both unfired rounds and factory brass after firing and compare that to the brass he is having issues with.

Also as Diverdon suggested eliminating the possibility of any gunk in the bolt body and firing pin assembly would be advisable, it being a new rifle and not knowing if it was properly cleaned before or after delivery is unknown.

So here is some additional data. The base to shoulder datum measurement taken on 5 Hornady rounds (140 gr ELD-M) is 1.551 in +/- .001 in. The base to shoulder datum measurement on my reloads is 1.557 in +/- less than .001 in. So my reloads actually have .006 less headspace than the factory loads. Also, I just fired 20 primed cases (no powder or projectiles) 10 previously fired and resized Hornady cases with Federal 210 match primers and 10 Lapua previously fired and resized cases with Federal 205M small rifle match primers. There were NO failures to fire. I did this to see if there might be something hinky with my reloading procedure with respect to the primers. The bolt on this Curtis action is very easy to disassemble, so next I will do that and give it a good bath. Thank you all for your suggestions. Please continue if you think of anything else. At this point it looks like a compatibilty issue with the CCI primers since I have tried two different lots of them.

Ok , just to clarify you said you bumped the shoulders back .005" from fired dimension. Your dimension of unfired is 1.551" and bumped back .005" is 1.557" that would mean you chamber is out of spec or there's something being lost in translation.

Ok , just to clarify you said you bumped the shoulders back .005" from fired dimension. Your dimension of unfired is 1.551" and bumped back .005" is 1.557" that would mean you chamber is out of spec or there's something being lost in translation.

I believe OP is saying that the unfired factory Hornady is 1.551”.

His reloads, after being bumped back 0.005”, are at 1.557”. In other words, 0.006” longer than the Hornady factory load which is properly working.

I believe OP is saying that the unfired factory Hornady is 1.551”.

His reloads, after being bumped back 0.005”, are at 1.557”. In other words, 0.006” longer than the Hornady factory load which is properly working.

But that would also mean a total .011" measured growth from new to fired dimension, that's a little extreme isn't it ?

OK. The setback I posted earlier was from the Bergara chamber, since I already had rounds loaded for that rifle I used breaking in the new MPA. I just measured the base to shoulder datum distance for the rounds actually fired in the MPA and got 1.559 +/- < .001 in. So the setback for the MPA is really .002 in. Thanks for spotting that.

OK. The setback I posted earlier was from the Bergara chamber, since I already had rounds loaded for that rifle I used breaking in the new MPA. I just measured the base to shoulder datum distance for the rounds actually fired in the MPA and got 1.559 +/- < .001 in. So the setback for the MPA is really .002 in. Thanks for spotting that.

That sounds a bit better then, just making sure I wasn't missing something.

The growth is from 1.551 to 1.559 using factory ammo.OK. The setback I posted earlier was from the Bergara chamber, since I already had rounds loaded for that rifle I used breaking in the new MPA. I just measured the base to shoulder datum distance for the rounds actually fired in the MPA and got 1.559 +/- < .001 in. So the setback for the MPA is really .002 in. Thanks for spotting that.

I had a friend that recently had a problem with CCI 450s I think he ended up getting a stronger spring. I had the problem with my reloads not firing in a 223 and it was a headspace issue. Excessive headspace which I wouldn’t think would be the case with yours but you never know.

I'd run the Federal primers. Worked on couple custom actions that had problems with misfire. CCI Primer hit looked good, switched to new box CCI primers, switched brass, tried neck sized only, and still had misfires. Used Federal primers and problem disappeared. Just my thinking that some custom actions running on the edge of perfection.

I have a new 6.5 CM MPA build (planning to talk with them tomorrow) that is misfiring on 1/3 of my handloads. These are loads that have never misfired in my Bergara. They consist of Lapua brass, fired 3-4X, fully resized .005 shorter on headspace than post firing and within spec. Case length is 1.92 in. Primers are CCI 450. I have tried a new box of primers from a different lot without benefit. Each round is hand primed and primers well seated. The misfire cartridges show what looks like an adequate pin strike indentation. Powder is 41.5 gr of RL 16 and bullets are Berger 130 hybrids. COAL is 2.825. I have fired factory Hornady 140 gr Match ammo with no misfires. The factory ammo uses a large rifle primer, whereas the Lapua brass uses a small rifle primer. The action is a Curtis Custom Axiom. I have picked up a box of Federal small rifle primers and plan to try that, and have some Hornady brass I can load and try, but would appreciate any suggestions or insights. Thanks in advance.

I have 2 Curtis Axioms and was having light strikes/ misfires with Both with with CCI 450's. They have updated the firing pins and the rear shroud part that the firing pins are attached to. Also, Timney triggers were not the best choice for these actions I was told. After Joel Russo sent the updated parts and installing TriggerTech triggers, the problems are gone. Hope this helps. Joels Cell # is on the Curtis site

Thank you JPL-ATX. I will contact Joel. MPA may need to make arrangements for the replacements. In the meanwhile I started using Federal 205 primers and have not had a problem with them. My trigger is a TriggerTech.I have 2 Curtis Axioms and was having light strikes/ misfires with Both with with CCI 450's. They have updated the firing pins and the rear shroud part that the firing pins are attached to. Also, Timney triggers were not the best choice for these actions I was told. After Joel Russo sent the updated parts and installing TriggerTech triggers, the problems are gone. Hope this helps. Joels Cell # is on the Curtis site

I just had a similar light strike issue on a custom action that was resolved this way. Though I using a Timney Calvin Elite Adj.They have updated the firing pins and the rear shroud part that the firing pins are attached to.

Man, I really like the 7 1/2s, and nobody ever seems to talk about them. They just work, all the time, and get better ES and SD (not by huge margins, but 1 or 2 counts in my book) with them over the CCI BR primers.Switch to a diferent primer. Rem 7 1/2 works good.

Well the Federal 205 primers have so far all fired, but honestly it seems to me that a $3000 rifle ought to shoot any legit primer I load so I can see what gives me the best results. Good to know that some have found the Rem 7 1/2 to be another choice though.

Just spoke with Joel and my bolt is on its way back to Curtis for an update to the fire control system. Joel was very helpful. Great service from Curtis Custom. They will send it back to me the same day they receive it. Thanks to all who have helped!

I

I have pretty much standardized everything I can to using cci450 primers and never had a single misfire in everything from 223rem, 68spc, 308win and soon to be 65 Creedmoor.

My varmint rifle AR with a Jard 1-1/2# trigger has what I consider a weak ass trigger spring and has never failed to ignite a CCI450.

The reason most shooters use the CCI450 magnum primers is to handle higher pressure loads. If your firing spring pressure is marginal misfires will happen.

I have pretty much standardized everything I can to using cci450 primers and never had a single misfire in everything from 223rem, 68spc, 308win and soon to be 65 Creedmoor.

My varmint rifle AR with a Jard 1-1/2# trigger has what I consider a weak ass trigger spring and has never failed to ignite a CCI450.

Rule out the ammo in the first place. Get some factory loads and run um through. That will get you on the right track. Could be the rifle, could be the loads.

Got my bolt back today. I can’t say enough about the great treatment I received from Joel at Curtis Custom. I’ll be at the range Saturday with my grandson to check it out, set up the scope, and continue load workup. I’ll report on the results thereafter. Thanks again to everyone who contributed to the thread.

Similar threads

- Replies

- 23

- Views

- 1K

- Replies

- 5

- Views

- 301

- Replies

- 14

- Views

- 804

- Replies

- 19

- Views

- 1K

- Replies

- 3

- Views

- 216