I'm at the point in my reloading where I'd like to branch out a bit.

My question is do you guys think it's worth it or beneficial to outside neck turn brass for factory guns?

All my handloads are plenty fine for hunting but never hurts to improve if possible.

Also if bullet concentricity and neck tension affect accuracy surely neck turning will help even on a factory barrel?

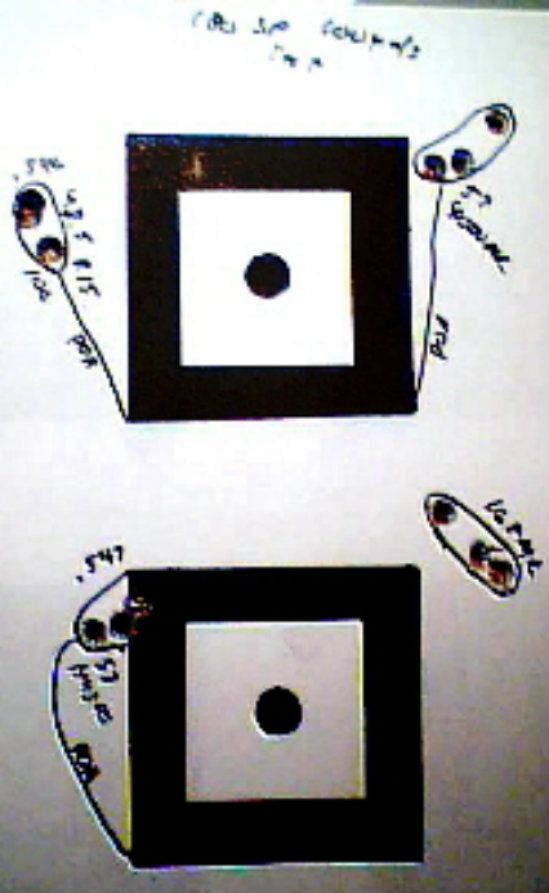

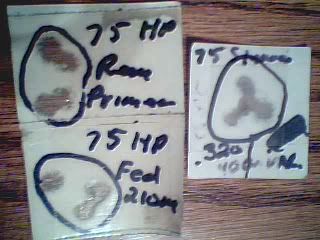

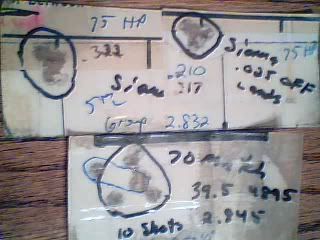

This got me to thinking. Last year I bought a Savage 110 lightweight hunter in 260. My first hand loads were no where near max pressures and seated .010 jammed. Seems jamming would greatly reduce the ability for a bullet to wobble in the lands?

With the bullets .010 jammed this rifle shot incredibly well for a skinny barrelled gun.

http://cruton.bmg.uab.edu/pics/savage/DSC02636.JPG

So to recap:

1. Beneficial to outside neck turn for factory chambers?

2. Does bullet jamming reduce ability for bullet to wobble in lands thus improving accuracy?

thanks

My question is do you guys think it's worth it or beneficial to outside neck turn brass for factory guns?

All my handloads are plenty fine for hunting but never hurts to improve if possible.

Also if bullet concentricity and neck tension affect accuracy surely neck turning will help even on a factory barrel?

This got me to thinking. Last year I bought a Savage 110 lightweight hunter in 260. My first hand loads were no where near max pressures and seated .010 jammed. Seems jamming would greatly reduce the ability for a bullet to wobble in the lands?

With the bullets .010 jammed this rifle shot incredibly well for a skinny barrelled gun.

http://cruton.bmg.uab.edu/pics/savage/DSC02636.JPG

So to recap:

1. Beneficial to outside neck turn for factory chambers?

2. Does bullet jamming reduce ability for bullet to wobble in lands thus improving accuracy?

thanks

Attachments

Last edited: