Was helping a friend of mine who was having issues with his rifle and am hoping someone here has an answer or solution to this problem

There are two different rifles pictured, both are Rem 700 long actions (300 WM), they both say Remington Model 700 on the left side of the action.

Tan stock rifle: Rem 700 300 WM stainless action and barrel. Barrel is just a regular light hunting-profile.

Black stock rifle: Rem 700 300 WM stainless action and barrel. Barrel is a fluted Sendero.

As far as he knows both are factory rifles and have not had any modifications to the action or barrel.

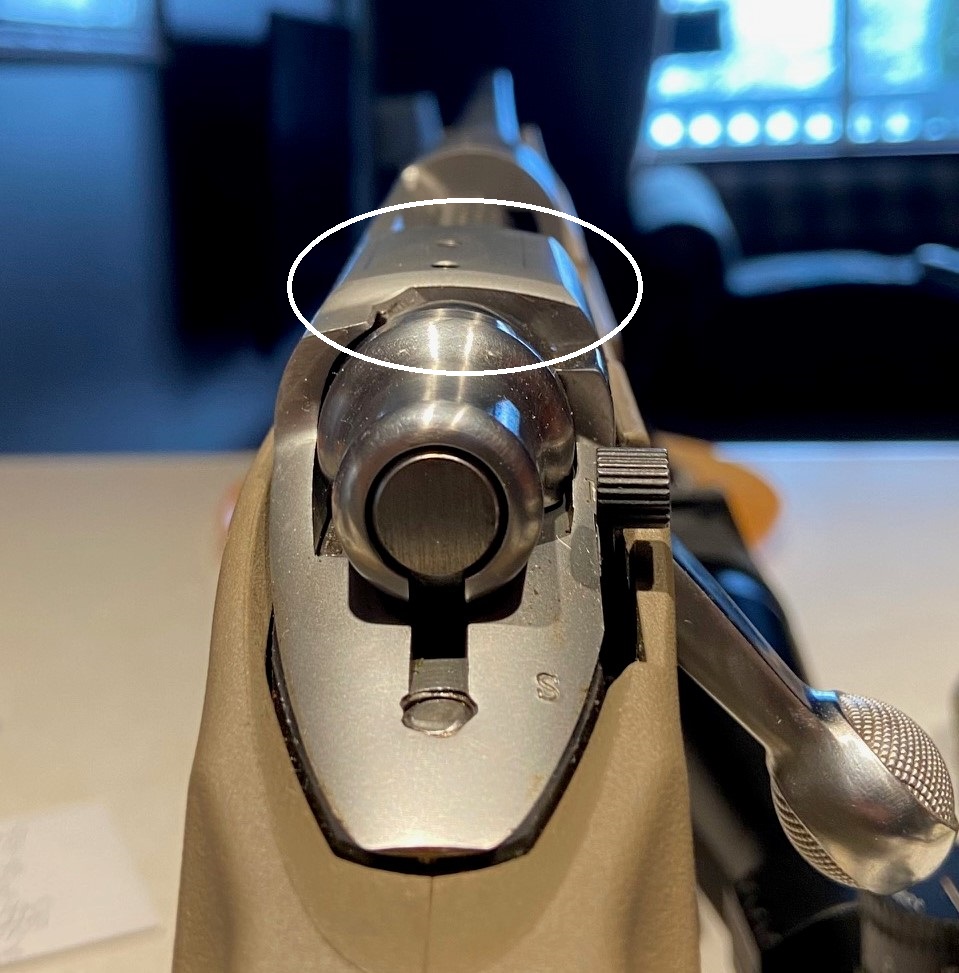

The issue is where the scope base gets screwed into the rear part of the action. The back part on one of the rifles (the one with the tan stock) is canted a bit to the right and will not allow the rear part of the scope base to fit flush with the action. The other rifle (the one with the black stock) is level and the scope base fits perfectly. It doesn't look quite as different in the pics than it does in person but the difference should still be pretty clear. He has two bases, one is an EGW base and the other is a Nightforce base, they both are perfect with the black stock rifle, but neither will fit the one with the tan stock. The one with the tan stock is older than the the one with the black stock by many years (exact age not known).

Did Remington change something over the years? Is there a base that will fit the tan stock rifle? Manufacturing defect? Or something else?

We tried looking online but couldn't find anything.

If anyone knows of this difference and/or has a solution to this please let me know!

I also added a few pics of the front view and they too are different (see circles).

Thanks in advance!!!

There are two different rifles pictured, both are Rem 700 long actions (300 WM), they both say Remington Model 700 on the left side of the action.

Tan stock rifle: Rem 700 300 WM stainless action and barrel. Barrel is just a regular light hunting-profile.

Black stock rifle: Rem 700 300 WM stainless action and barrel. Barrel is a fluted Sendero.

As far as he knows both are factory rifles and have not had any modifications to the action or barrel.

The issue is where the scope base gets screwed into the rear part of the action. The back part on one of the rifles (the one with the tan stock) is canted a bit to the right and will not allow the rear part of the scope base to fit flush with the action. The other rifle (the one with the black stock) is level and the scope base fits perfectly. It doesn't look quite as different in the pics than it does in person but the difference should still be pretty clear. He has two bases, one is an EGW base and the other is a Nightforce base, they both are perfect with the black stock rifle, but neither will fit the one with the tan stock. The one with the tan stock is older than the the one with the black stock by many years (exact age not known).

Did Remington change something over the years? Is there a base that will fit the tan stock rifle? Manufacturing defect? Or something else?

We tried looking online but couldn't find anything.

If anyone knows of this difference and/or has a solution to this please let me know!

I also added a few pics of the front view and they too are different (see circles).

Thanks in advance!!!