These pieces of brass are from my 18” OBR that I am developing a load for.

This first series came from a ladder shot with 42.0 to 45.0 gr of Varget loaded in new Win brass and capped with 147 gr SMK seated with OAL of 2.800 and Rem 9 ½ primers. No MV data since my chrono was down that day.

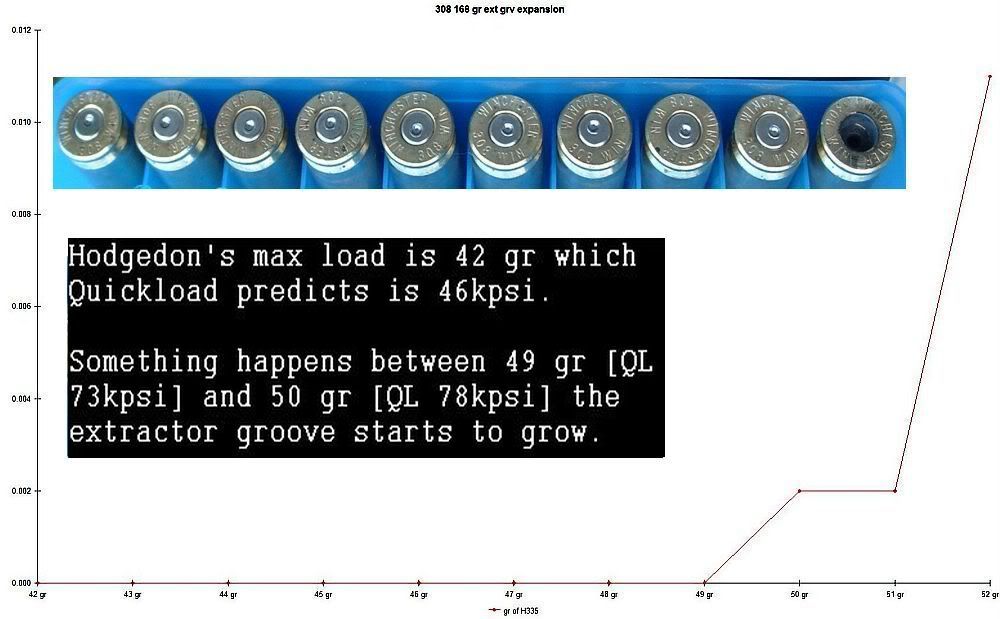

This second series of brass came from two loads I was testing – the top row was with 43.5 and the bottom 43.0 gr of Varget. Both five round groups ended up being sub MOA. Chrono was working and the average MV was 2428 ft/sec (43.0 gr) and 2455 ft/sec (43.5 (edited) gr).

I am currently interested in using the 43.0 gr weight since it was the most accurate (0.827 MOA). In the ladder group, I see a little primer flattening in all the brass with increasing degree of flattening at the higher powder range although some primer radius was still visible at 45.0 gr. Primer crater was also visible in all the primers. Extractor mark was visible at the three highest weights.

In the brass from the two loads (i.e. 43.0 and 43.5 gr), slight primer flattening, cratering was visible in all the brass and interestingly extractor mark was visible in three out of five pieces of brass from each group.

The last graph shows the diameter of the brass case head described above together with two control groups i.e. five unfired Winchester cases and five fired WCC 7.62x51 NATO 147 gr. FMJ cases all fired from the same chamber.

This graph below summarize the data. First, the data for the unfired Win brass I put in as 41.00 grain (blue box) just so that it is in the graph. Second, the data from the WCC 7.62x51 NATO 147 gr. FMJ I put in as 46.00 gr. (red box) again so that it is in the graph.

The results appear to show a progressive increase in case head size going from 42.00 to 45.00 grains but with none of the currently tested Varget powder weight exceeding the WCC induced changes. The 43.00 gr. weight that I am currently interested in appears to be lower than that of the diameter seen for the WCC brass.

So my question is based on what I have described above, would it be reasonable to conclude that the 43.0 gr of Varget is a safe to shoot? I am developing the rounds for shooting at a 600 yards range.

Thanks ahead for your input.

This first series came from a ladder shot with 42.0 to 45.0 gr of Varget loaded in new Win brass and capped with 147 gr SMK seated with OAL of 2.800 and Rem 9 ½ primers. No MV data since my chrono was down that day.

This second series of brass came from two loads I was testing – the top row was with 43.5 and the bottom 43.0 gr of Varget. Both five round groups ended up being sub MOA. Chrono was working and the average MV was 2428 ft/sec (43.0 gr) and 2455 ft/sec (43.5 (edited) gr).

I am currently interested in using the 43.0 gr weight since it was the most accurate (0.827 MOA). In the ladder group, I see a little primer flattening in all the brass with increasing degree of flattening at the higher powder range although some primer radius was still visible at 45.0 gr. Primer crater was also visible in all the primers. Extractor mark was visible at the three highest weights.

In the brass from the two loads (i.e. 43.0 and 43.5 gr), slight primer flattening, cratering was visible in all the brass and interestingly extractor mark was visible in three out of five pieces of brass from each group.

The last graph shows the diameter of the brass case head described above together with two control groups i.e. five unfired Winchester cases and five fired WCC 7.62x51 NATO 147 gr. FMJ cases all fired from the same chamber.

This graph below summarize the data. First, the data for the unfired Win brass I put in as 41.00 grain (blue box) just so that it is in the graph. Second, the data from the WCC 7.62x51 NATO 147 gr. FMJ I put in as 46.00 gr. (red box) again so that it is in the graph.

The results appear to show a progressive increase in case head size going from 42.00 to 45.00 grains but with none of the currently tested Varget powder weight exceeding the WCC induced changes. The 43.00 gr. weight that I am currently interested in appears to be lower than that of the diameter seen for the WCC brass.

So my question is based on what I have described above, would it be reasonable to conclude that the 43.0 gr of Varget is a safe to shoot? I am developing the rounds for shooting at a 600 yards range.

Thanks ahead for your input.