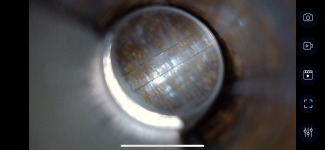

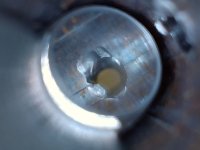

Just unpacked this new Wilson Combat 22" Super Sniper .224 barrel still in the factory sealed wrap. I took a look at the crown and could see heavy rusting right away without even using a light, with a light the whole inside of the end of the barrel looked reddish/orange. Pulled out the borescope and about the last 10" is heavy rust. I also hit a pretty good obstruction at the gas port, that's pretty ugly as well. Definitely the worst new barrel I've ever unpacked from a corrosion standpoint, or gas port.

Pretty amusing when the manufacturer's webpage has a video showing them scoping the barrel twice during production, including after the gas port is cut at final inspection I mean I'm sure it's possible it rusted after it left there, but that gas port sure didn't happen after it left. There's no way you could slide a bore scope past that and not feel it.

I mean I'm sure it's possible it rusted after it left there, but that gas port sure didn't happen after it left. There's no way you could slide a bore scope past that and not feel it.

Not sure if I should just return it to the vendor (they'll probably just repackage it for some other poor sucker) or get ahold of the manufacturer. I've had some ugly looking scoped barrels shoot well before but with that much corrosion it seems like it's just going to have problems with fowling and probably pitting even if it's cleaned up.

Just more evidence that I am a bad QC magnet, companies should pay me to buy their stuff just to get rid of the lemons.

Pretty amusing when the manufacturer's webpage has a video showing them scoping the barrel twice during production, including after the gas port is cut at final inspection

Not sure if I should just return it to the vendor (they'll probably just repackage it for some other poor sucker) or get ahold of the manufacturer. I've had some ugly looking scoped barrels shoot well before but with that much corrosion it seems like it's just going to have problems with fowling and probably pitting even if it's cleaned up.

Just more evidence that I am a bad QC magnet, companies should pay me to buy their stuff just to get rid of the lemons.

Last edited: