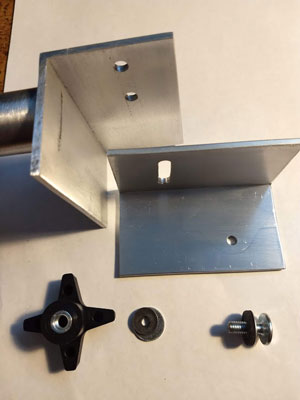

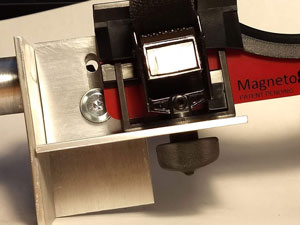

Cabin fever, needed something to do so figured I put this up. This is a design I'd put together with readily available materials. Uses a 1" bar so it can be hung with standard rings. 2" Angle aluminum. Cut down furniture bolt + handle. Key to making it work is the mount hole in the cradle needs to pressure fit the flat edge of the Magnetospeed against the inside of the cradle. The cradle slot needs to pressure fit against the rear of the fixed bracket. The bar needs to be cut and brazed perpendicular to the bracket. Pay attention to the distances of the brazed mount, too far in and you interfere with the barrel too far out and you won't have enough travel to properly set distance. Also, watch the cradle distance behind the Magnetospeed, too close and you can't plug it in when mounted, and may loose clearance for an allen if the bolt spins (see rubber washers for added friction on this connection point.) As for final fit and finish, I'm a function over form guy so don't care what it looks like and only use it for load workups.

- Thread starter Merovingian

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Working on one myself.

1" carbon fiber tube

1" flashlight mount

1" bar clamps

1" carbon fiber tube

1" flashlight mount

1" bar clamps

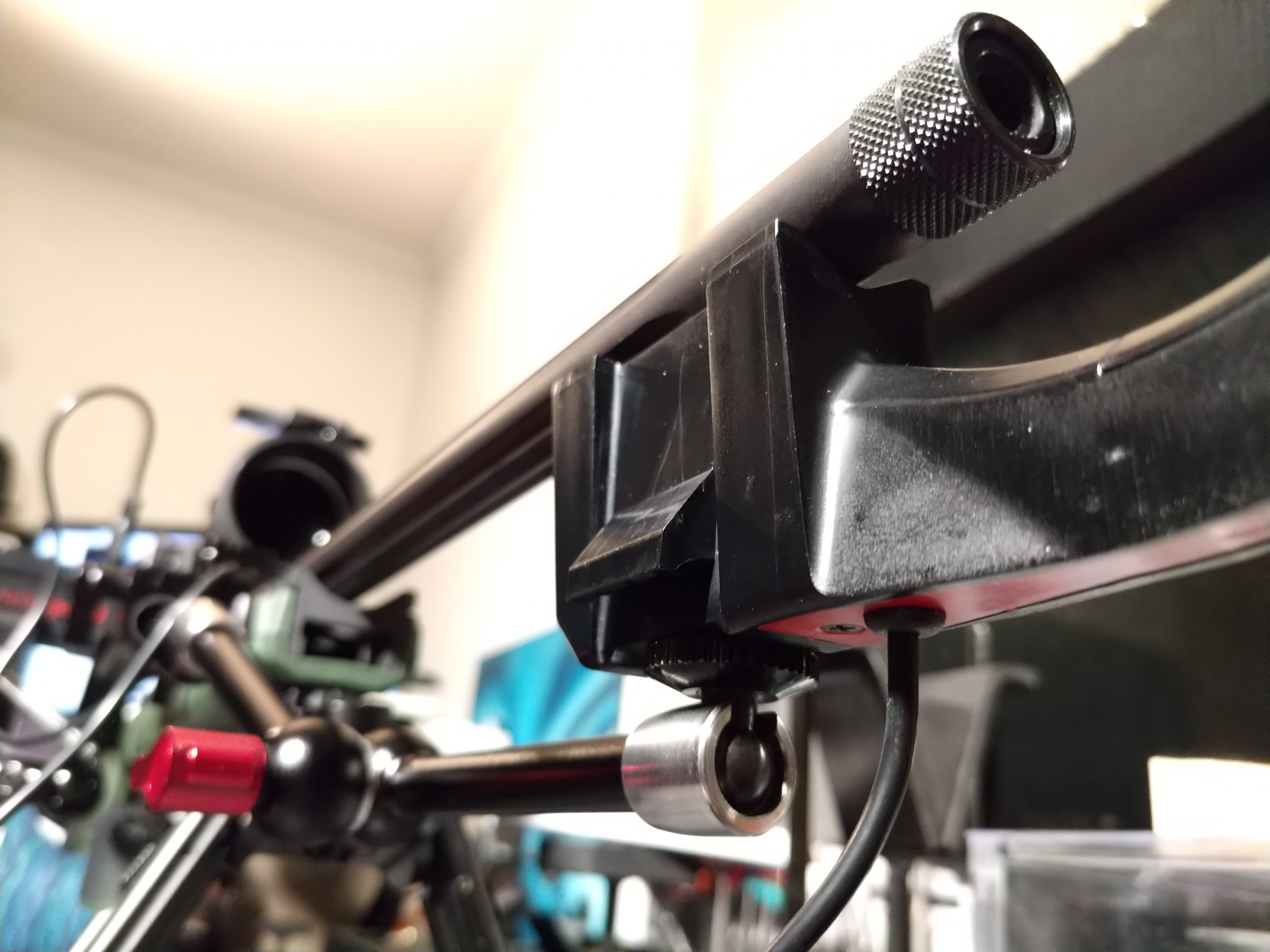

I added a 1/4-20 nut to the inside of my sporter, so I could use a magic arm with 15mm light weight rods to mount it to a picatinny rail.

Best part is the original mounting equipment is uneffected.

Best part is the original mounting equipment is uneffected.

How stable is it over multiple rounds?

I added a 1/4-20 nut to the inside of my sporter, so I could use a magic arm with 15mm light weight rods to mount it to a picatinny rail.

View attachment 7247409

Best part is the original mounting equipment is uneffected.

You know I tried CF and milling some CPVC brackets and couldn't get where I wanted to go. Have a good deal of metal work behind me so I ended up just doing something simple and in my wheelhouse. Worked out well in the end because that impact rated PVC ended up solving another issue. Used it to mill a follower insert. When you get it done, post it up here! Don't see many home builds and ones on the market are $$ for what they are. I think I'm into the aluminum unit for $25 with material to spare.

As for what would I do different: a. Smaller knob. That one turned out to be overkill. b. Trim the excess material back a bit. Just finished look thing. c. Spend some more time trying to use a PVC or Neoprene collet to drop the tube diameter and use in a 0 MOA low profile uni-mount rather than individual rings. I started down that road but wasn't very successful finding compatible/affordable parts and after my CF/PVC failure I just wanted to get it done. The rings I already had, and have a benefit in flexibility since I swap it between five different rigs that vary widely. d. May consider cutting the tube back a bit but that hasn't been an issue other than on a 300BLK SBR.

As for what would I do different: a. Smaller knob. That one turned out to be overkill. b. Trim the excess material back a bit. Just finished look thing. c. Spend some more time trying to use a PVC or Neoprene collet to drop the tube diameter and use in a 0 MOA low profile uni-mount rather than individual rings. I started down that road but wasn't very successful finding compatible/affordable parts and after my CF/PVC failure I just wanted to get it done. The rings I already had, and have a benefit in flexibility since I swap it between five different rigs that vary widely. d. May consider cutting the tube back a bit but that hasn't been an issue other than on a 300BLK SBR.

Nice! I've seen people using similar setups. Outside a heavy duty one for my bow vise, my experience with those ball joints hasn't been good LT. Are they holding up ok?I got the MPA spigot mount for more than $100. I hope Phil’s kids go to the college of their choice!

I tried it out a week ago and didn't have any issues with the arm, had to use a NATO clamp instead of a proper picatinny because of the mounting screw location. So that would slip a bit after a few rounds but you could just re-seat it and the bayonet stayed in the same spot. I plan to add another NATO clamp and that should give me enough surface area to prevent slippage.How stable is it over multiple rounds?

The arm I'm using was only 25$ or so and there are much stronger options. There is also the potential option of just using 15mm LW and skipping the arm since the bayonet is now threaded.

I'll be taking it out in the morning so we will see how it handles another 50-60rounds of 308

The ingenuity! Damn!

Is it pretty stable shot to shot? Doesnt try and walk?

Looks like it has some weight to it.Cabin fever, needed something to do so figured I put this up. This is a design I'd put together with readily available materials. Uses a 1" bar so it can be hung with standard rings. 2" Angle aluminum. Cut down furniture bolt + handle. Key to making it work is the mount hole in the cradle needs to pressure fit the flat edge of the Magnetospeed against the inside of the cradle. The cradle slot needs to pressure fit against the rear of the fixed bracket. The bar needs to be cut and brazed perpendicular to the bracket. Pay attention to the distances of the brazed mount, too far in and you interfere with the barrel too far out and you won't have enough travel to properly set distance. Also, watch the cradle distance behind the Magnetospeed, too close and you can't plug it in when mounted, and may loose clearance for an allen if the bolt spins (see rubber washers for added friction on this connection point.) As for final fit and finish, I'm a function over form guy so don't care what it looks like and only use it for load workups.

Haven't weighed it, but it doesn't weight much. I was actually surprised to find out it's very comparable to a CF unit I did that didn't work out as well as I'd hoped. Give me a couple days and I'll post weight. As for any walking, it's rock solid.Looks like it has some weight to it.

15 oz w/ rings + 7 oz MS. So it's less than 1.5lb hanging completely installed.Looks like it has some weight to it.

That's not near as bad as I was thinking15 oz w/ rings + 7 oz MS. So it's less than 1.5lb hanging completely installed.

I tried it out a week ago and didn't have any issues with the arm, had to use a NATO clamp instead of a proper picatinny because of the mounting screw location. So that would slip a bit after a few rounds but you could just re-seat it and the bayonet stayed in the same spot. I plan to add another NATO clamp and that should give me enough surface area to prevent slippage.

The arm I'm using was only 25$ or so and there are much stronger options. There is also the potential option of just using 15mm LW and skipping the arm since the bayonet is now threaded.

View attachment 7247423

I'll be taking it out in the morning so we will see how it handles another 50-60rounds of 308

If you have a QD sling mount or something similar that has a recoil lug you could put that behind the NATO picatinny mount to keep it from shifting on the rail.

I use this mount from wiser precision it is very light and rigid and works well also attaches or removes quickly and easily to a rail mounted on the forend of your stock just make sure the rail is long enough to accommodate this and your bipodCabin fever, needed something to do so figured I put this up. This is a design I'd put together with readily available materials. Uses a 1" bar so it can be hung with standard rings. 2" Angle aluminum. Cut down furniture bolt + handle. Key to making it work is the mount hole in the cradle needs to pressure fit the flat edge of the Magnetospeed against the inside of the cradle. The cradle slot needs to pressure fit against the rear of the fixed bracket. The bar needs to be cut and brazed perpendicular to the bracket. Pay attention to the distances of the brazed mount, too far in and you interfere with the barrel too far out and you won't have enough travel to properly set distance. Also, watch the cradle distance behind the Magnetospeed, too close and you can't plug it in when mounted, and may loose clearance for an allen if the bolt spins (see rubber washers for added friction on this connection point.) As for final fit and finish, I'm a function over form guy so don't care what it looks like and only use it for load workups.

Kinda gets the "gray matter" humming... Now I got like 50 new design possibilities floating around and ...It's yall's fault!

Great thread. Figured there had to be some work arounds to direct barrel mount.

I just ordered the Wiser mount myself. For $100 it just wasn’t worth my time to try and cobble something together.

features that sold me.

1. System will fit anything I have, from a 338 RPR to an AR10 6.5 CM to my .22 chassis rifle

2. Lots of adjustment

3. Holds the display unit

4. Carbon Fiber

features that sold me.

1. System will fit anything I have, from a 338 RPR to an AR10 6.5 CM to my .22 chassis rifle

2. Lots of adjustment

3. Holds the display unit

4. Carbon Fiber

I’ve got one it works very wellI just ordered the Wiser mount myself. For $100 it just wasn’t worth my time to try and cobble something together.

features that sold me.

1. System will fit anything I have, from a 338 RPR to an AR10 6.5 CM to my .22 chassis rifle

2. Lots of adjustment

3. Holds the display unit

4. Carbon Fiber

Similar threads

- Replies

- 3

- Views

- 351

- Replies

- 5

- Views

- 685

- Replies

- 14

- Views

- 555

- Replies

- 57

- Views

- 7K