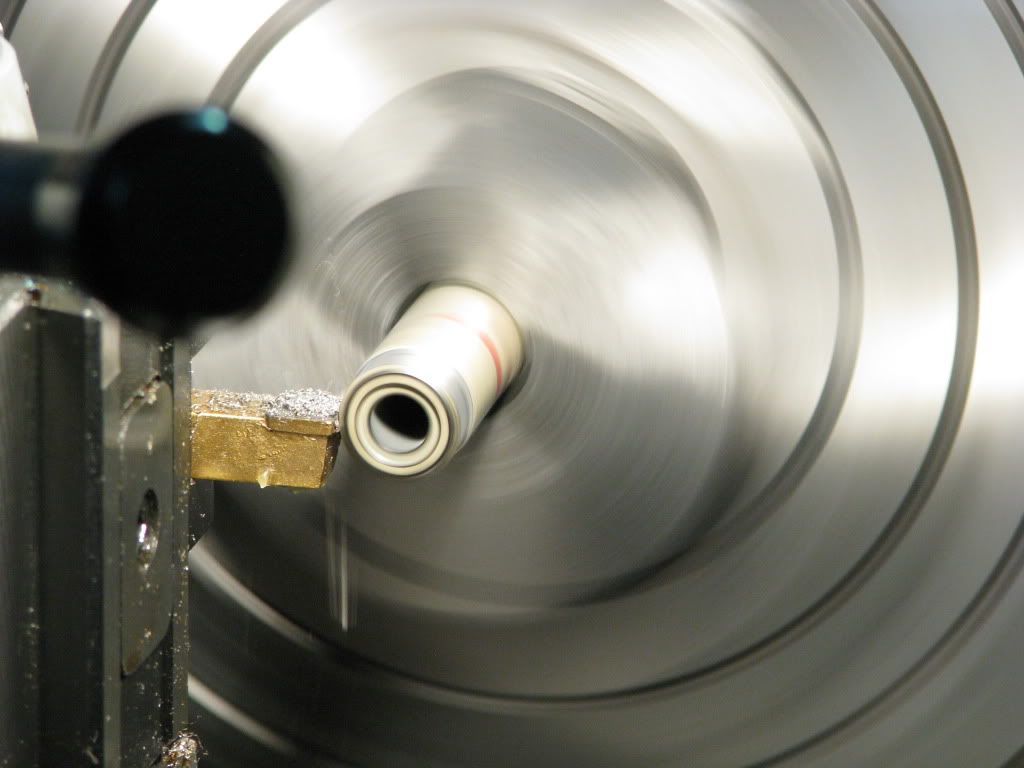

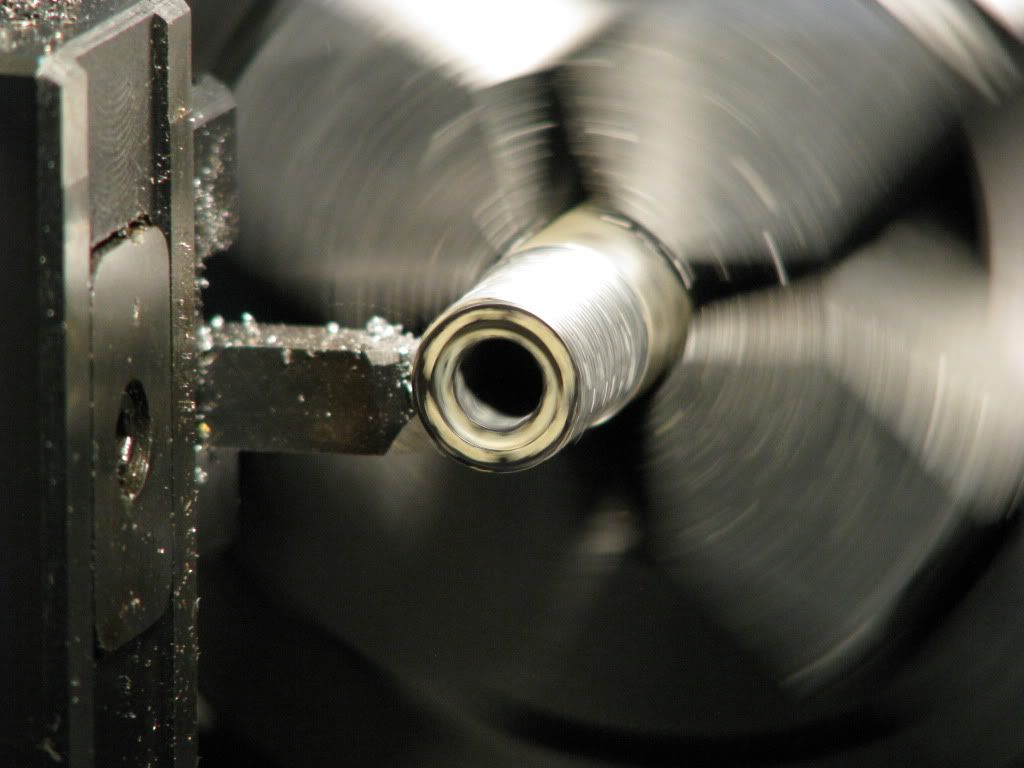

The lathe adventures.

Most of this is already in the ongoing LR thread on a local forum.

<span style="font-weight: bold">

Special thanks to Shiraz at Grizzly.com.</span>

http://www.grizzly.com/products/Gunsmith-s-Bench-Top-Lathe-with-Stand/G4003G

It was the stand out for entry level lathes in our bid to become more self sufficient. Obviously a Bridgeport or Southbend would be ideal but the extreme cost of their equipment eliminated them at this time. Las Vegas' lack of gunsmiths that can/will accommodate precision rifles with less than 6mo turn around time was a driving force behind our decision to learn.

We all have put in a great deal of time, effort and expense in to our shooting and competing but it appears to be paying off. Hopefully this new gunsmithing/rifle building endeavor will be just as fun and rewarding. After months of reading, watching you tube vids and picking the brains of the experienced, its now time to practice hands on with steel stock and re-learn the machine. It will be a while before any of us even get close to building a rifle but that day is now one step closer.

Toubalcain's videos have been a great help along with STR's gunsmithing vids

http://www.youtube.com/watch?v=hrDr4rYLiAk&feature=player_embedded

Looking forward to pizza, beer and many afternoons spent in the 110F garage working on new projects.

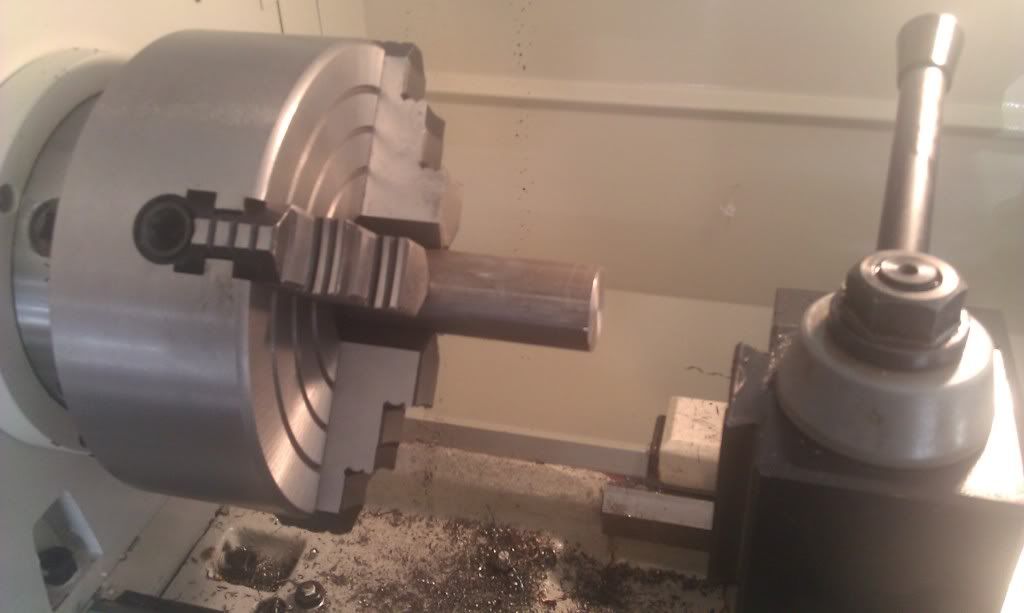

Even though its one of the smaller lathes out there it still weighs in around 1500lbs. I think every one should have a crane... or at least have a friend with one :thumbup1:

Most of this is already in the ongoing LR thread on a local forum.

<span style="font-weight: bold">

Special thanks to Shiraz at Grizzly.com.</span>

http://www.grizzly.com/products/Gunsmith-s-Bench-Top-Lathe-with-Stand/G4003G

It was the stand out for entry level lathes in our bid to become more self sufficient. Obviously a Bridgeport or Southbend would be ideal but the extreme cost of their equipment eliminated them at this time. Las Vegas' lack of gunsmiths that can/will accommodate precision rifles with less than 6mo turn around time was a driving force behind our decision to learn.

We all have put in a great deal of time, effort and expense in to our shooting and competing but it appears to be paying off. Hopefully this new gunsmithing/rifle building endeavor will be just as fun and rewarding. After months of reading, watching you tube vids and picking the brains of the experienced, its now time to practice hands on with steel stock and re-learn the machine. It will be a while before any of us even get close to building a rifle but that day is now one step closer.

Toubalcain's videos have been a great help along with STR's gunsmithing vids

http://www.youtube.com/watch?v=hrDr4rYLiAk&feature=player_embedded

Looking forward to pizza, beer and many afternoons spent in the 110F garage working on new projects.

Even though its one of the smaller lathes out there it still weighs in around 1500lbs. I think every one should have a crane... or at least have a friend with one :thumbup1: