This weekend I loaded up some .308 165 smk with 42 gr of wc846. Using blc2 data 42 gr is middle of the road. I used a complied data book that has speer, sierra, hornady and 4 or 5 more books worth of data on .308 to come to that conclusion..

I loaded 10 but only sent 4 down the tube. On three of them the bolt was getting stuck.. I have had this done with some reloads I bought at a chain store.. I also had some factory win ammo 150 gr coreloc. They did just fine in the savage fp10.

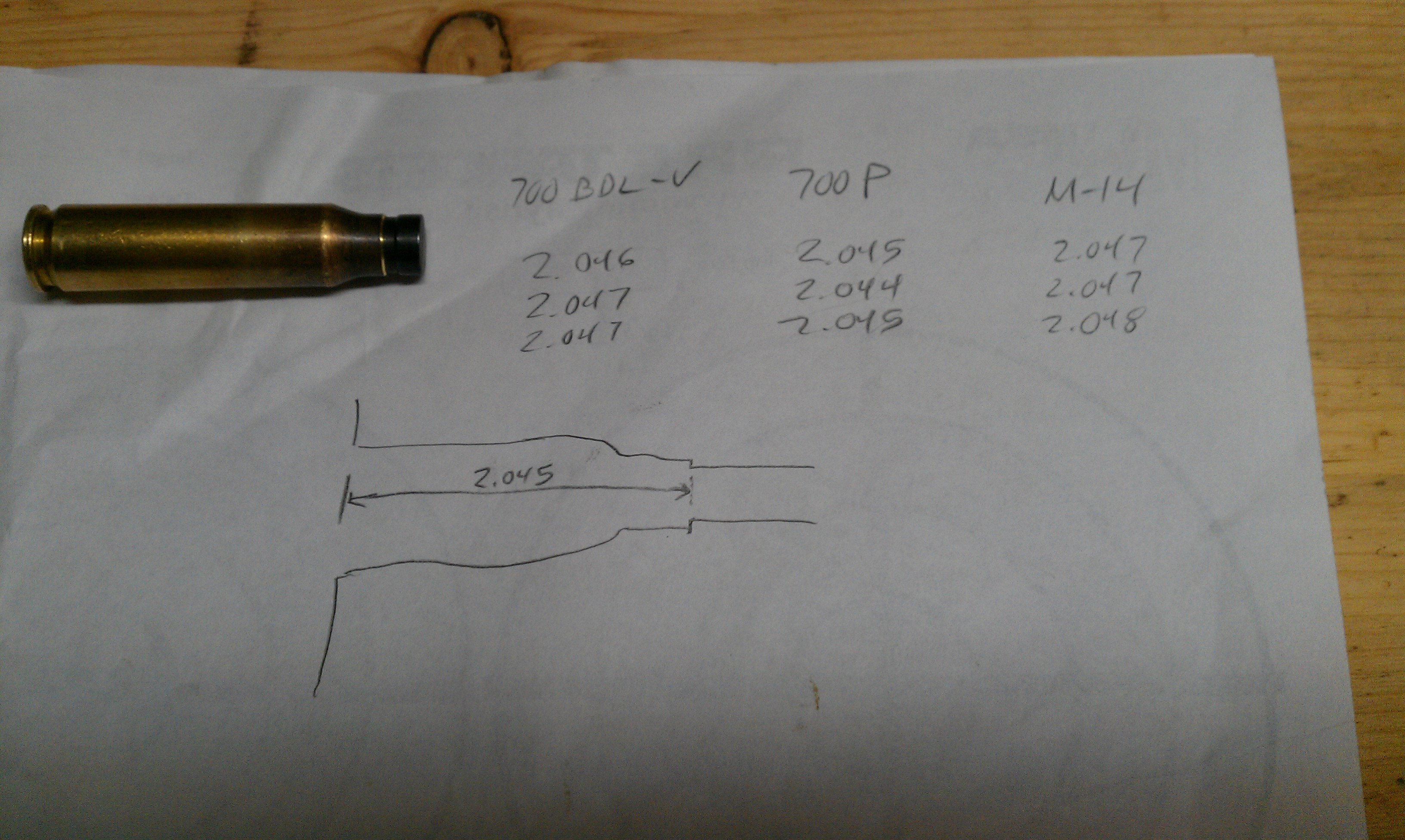

I got back and measured the cases...

both the factory and the reloaded brass expanded the same.

Neck went from .336 to .345 on the reloads and .333 to .345 on the factory.

Case body went from .469 to .471 on the reloads and .464 to .471 on the factory.

but I noticed on the reloads I must have gotten into my untrimmed brass because the factory was 2.010(starting at 2.005) but the reloads where 2.023 to 2.027.

I didn't see anything wrong with the primers or any other brass issues. so do you think it was a too long of case problem or a over pressure somehow issue.. or can too long of a case cause a over pressure issue.. I didn't use any crimp on the bullets and loaded them to max coal of 2.80

Thanks

BR

I loaded 10 but only sent 4 down the tube. On three of them the bolt was getting stuck.. I have had this done with some reloads I bought at a chain store.. I also had some factory win ammo 150 gr coreloc. They did just fine in the savage fp10.

I got back and measured the cases...

both the factory and the reloaded brass expanded the same.

Neck went from .336 to .345 on the reloads and .333 to .345 on the factory.

Case body went from .469 to .471 on the reloads and .464 to .471 on the factory.

but I noticed on the reloads I must have gotten into my untrimmed brass because the factory was 2.010(starting at 2.005) but the reloads where 2.023 to 2.027.

I didn't see anything wrong with the primers or any other brass issues. so do you think it was a too long of case problem or a over pressure somehow issue.. or can too long of a case cause a over pressure issue.. I didn't use any crimp on the bullets and loaded them to max coal of 2.80

Thanks

BR