Hiders...

I'm having a problem with what I believe is primary extraction. Rifle is a Remage G prefix with a Bartlein barrel in 223. After firing, I lift the bolt to where it contacts the extraction ramp and it won't go any further. It doesn't slide with the angle of the ramp and the bolt will not pull back to extract. There seems to be no primary extraction. The bolt doesn't pull right out, but takes a little whack to break it free so I can extract. This happens with factory and reloads.

In doing some search fu... there seems to be alot of space between the bolt handle and the receiver when in the cocked position, but I don't have feeler gauges to get an exact measurement. I am not a gunsmith and I am still learning, but from what I'm seeing..... is this due to lack of primary extraction?

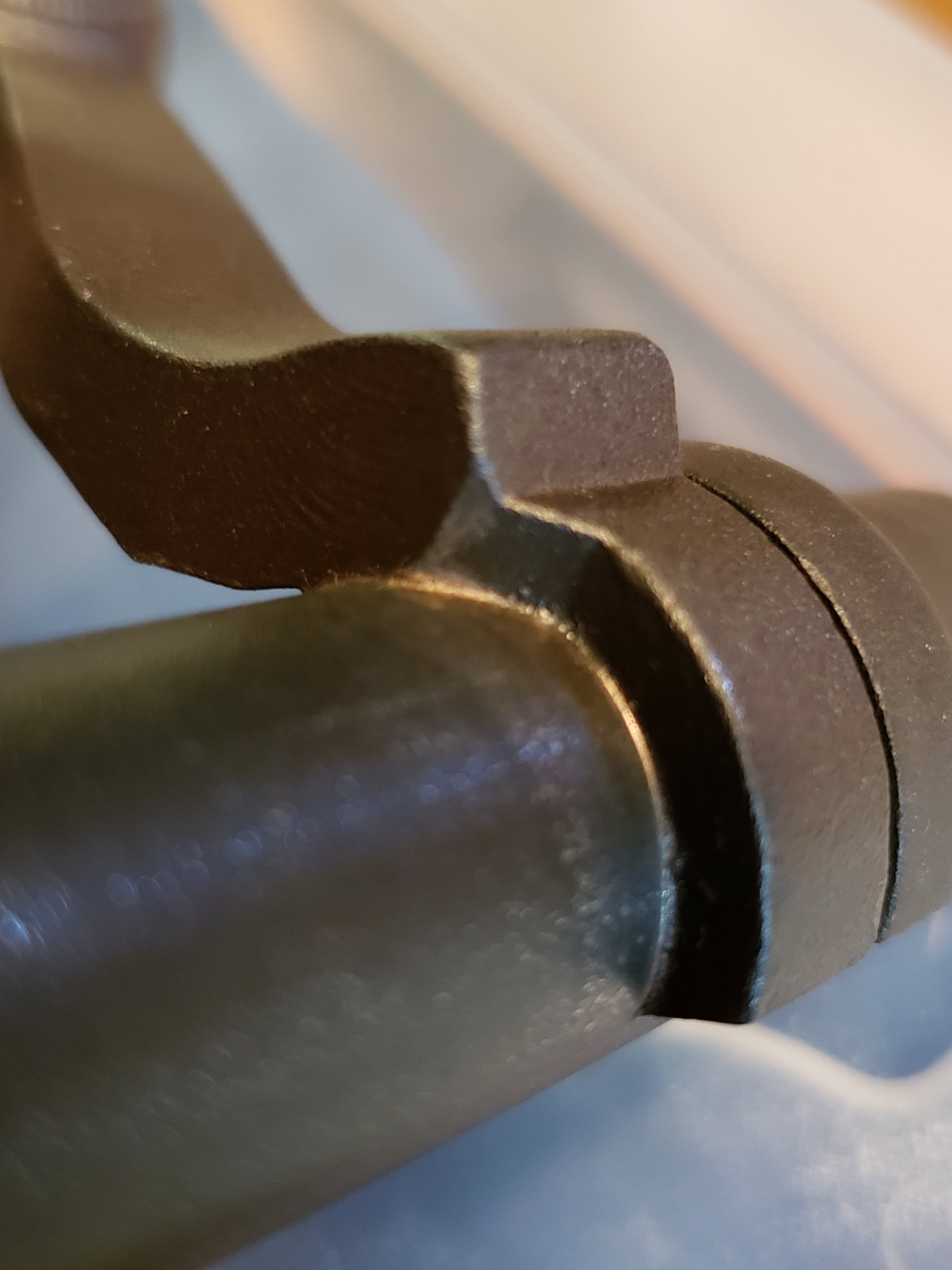

I will attach pics of the contact points on the extracting ramp of the receiver and the bolt handle angle. The lighter marks are where they make contact. On my 2 other Rems, the contact wear is 3x - 4x the area of this one, and I don't seem to have any problems.

Thanks in advance.

Will

I'm having a problem with what I believe is primary extraction. Rifle is a Remage G prefix with a Bartlein barrel in 223. After firing, I lift the bolt to where it contacts the extraction ramp and it won't go any further. It doesn't slide with the angle of the ramp and the bolt will not pull back to extract. There seems to be no primary extraction. The bolt doesn't pull right out, but takes a little whack to break it free so I can extract. This happens with factory and reloads.

In doing some search fu... there seems to be alot of space between the bolt handle and the receiver when in the cocked position, but I don't have feeler gauges to get an exact measurement. I am not a gunsmith and I am still learning, but from what I'm seeing..... is this due to lack of primary extraction?

I will attach pics of the contact points on the extracting ramp of the receiver and the bolt handle angle. The lighter marks are where they make contact. On my 2 other Rems, the contact wear is 3x - 4x the area of this one, and I don't seem to have any problems.

Thanks in advance.

Will

Last edited: