Good morning guys. Needing some help and advise. I recently purchased a proof carbon prefit in 7saum for my tikka t3x and went threw factory suggested brake in and load development. I am noticing a very consistent cold bore shot that is a .5 mil low and .5 mil to the right and after that first cold bore shot the rifle will group .5 moa at point of aim. This is a hunting rifle so first shot accuracy is a must. My question is this normal or something I can fix or file a warranty clam? Iv gone threw the entire rifle for torque specks and tested the optic on a know rifle. Shooting adg brass 168g Berger vld pushed by h4350. Any help would be greatly appreciated guys.

- Thread starter Chance08

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cold bore deviation is a thing, but if it’s consistent then you’ve just got to keep it in mind during that initial shot. It’s definitely a pain when you’ve got a whole mental check list to do before the shot and you need to remember what your cold bore hold is.

ridgelineshooting.com

ridgelineshooting.com

UNDERSTANDING COLD BORE - Ridgeline Defense

In this post we look at the repeatable phenomena of cold bore. We also look at other factors that drive variation shot to shot but are not repeatable.

Is your cold bore shot from a fresh clean bore? If so, after you confirm zero and dope leave the rifle "shot in" as I call it. Leave it dirty till it needs cleaned.

That’s a question I was going to ask as well as if other shooters are experiencing the same shift with that rifle.Is your cold bore shot from a fresh clean bore? If so, after you confirm zero and dope leave the rifle "shot in" as I call it. Leave it dirty till it needs cleaned.

Cold bore shooters are more common than cold bore barrel issues.

No sir its from a Fouled bore the rifle only has 60 rounds threw itIs your cold bore shot from a fresh clean bore? If so, after you confirm zero and dope leave the rifle "shot in" as I call it. Leave it dirty till it needs cleaned.

Did you install the barrel, and if so, what torque?No sir its from a Fouled bore the rifle only has 60 rounds threw it

I installed it myself and called proof and they recommended 75fp and checked with go/no go gaugesDid you install the barrel, and if so, what torque?

Ok, I torque Tikkas to 90 ft. lbs. The factory barrels are beyond that for sure. Just a theory, but maybe the first shot is torquing the barrel, that may explain the low and right first shot. If the shift to zero is up and left that would correspond with right twist rifling. I would try torquing to 90. What muzzle device are you using? If any.No sir its from a Fouled bore the rifle only has 60 rounds threw it

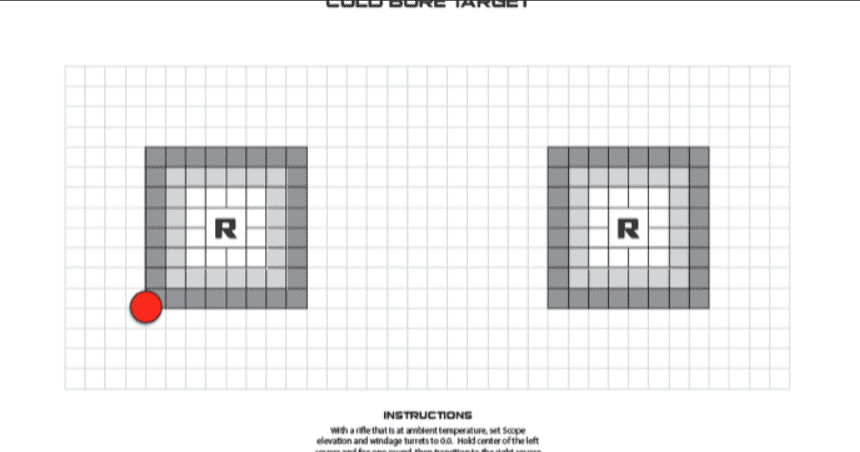

Iv gotten the same results with a silencer co asr break and with just a straight thread protecter covering the muzzle threads. Picture is at 300 yardsOk, I torque Tikkas to 90 ft. lbs. The factory barrels are beyond that for sure. Just a theory, but maybe the first shot is torquing the barrel, that may explain the low and right first shot. If the shift to zero is up and left that would correspond with right twist rifling. I would try torquing to 90. What muzzle device are you using? If any.

Attachments

alright, I would try torquing to 90 then. It's any easy thing to try before considering contacting proof.Iv gotten the same results with a silencer co asr break and with just a straight thread protecter covering the muzzle threads. Picture is at 300 yards

Id second what Fisher said. Add some torque, and I dont think the exact amount matters as long as you can vice the barrel securely and you have a good wrench. 90, 100, 125 ft lbs, whatever.Iv gotten the same results with a silencer co asr break and with just a straight thread protecter covering the muzzle threads. Picture is at 300 yards

I appreciate it guys I’ll give it a shot and see what happensId second what Fisher said. Add some torque, and I dont think the exact amount matters as long as you can vice the barrel securely and you have a good wrench. 90, 100, 125 ft lbs, whatever.

no way it's the torque. I shot f class with guys that would barely torque to 50 and would not experience shift. The amount of headspace change with theta little rotation is virtually zero. I would check the action screws and look at space at lug nut I would suspect bedding may be of more use than torquing barrel.

Also first round shift is a real thing. but yours sounds a bit extreme. are you cleaning barrel every time you shoot?

Also first round shift is a real thing. but yours sounds a bit extreme. are you cleaning barrel every time you shoot?

No sir it’s a fouled barrel And action screws are torqued to 65 inch poundsno way it's the torque. I shot f class with guys that would barely torque to 50 and would not experience shift. The amount of headspace change with theta little rotation is virtually zero. I would check the action screws and look at space at lug nut I would suspect bedding may be of more use than torquing barrel.

Also first round shift is a real thing. but yours sounds a bit extreme. are you cleaning barrel every time you shoot?

I agree, but would point out that the F class guys are likely shooting hand fitted barrels, with much tighter clearance in the threads. This is an easy way for the OP to check a box before he goes through the warranty return process.no way it's the torque. I shot f class with guys that would barely torque to 50 and would not experience shift. The amount of headspace change with theta little rotation is virtually zero. I would check the action screws and look at space at lug nut I would suspect bedding may be of more use than torquing barrel.

Also first round shift is a real thing. but yours sounds a bit extreme. are you cleaning barrel every time you shoot?

What’s that other one that isn’t circled? What’s a 5 round look like? What do two different groups look like.Iv gotten the same results with a silencer co asr break and with just a straight thread protecter covering the muzzle threads. Picture is at 300 yards

I’d say with just 60 rounds on it this is just you seeing a fluke and your groups are actually that big.

That other one that isn’t circled is the cold bore shot and then shot 2,3,4 are circled to show the difference. Iv even waited for barrel to cool down all the way and it still throws that first shot offWhat’s that other one that isn’t circled? What’s a 5 round look like? What do two different groups look like.

I’d say with just 60 rounds on it this is just you seeing a fluke and your groups are actually that big.

Have you had someone else shoot it... just to see if it does the same thing for them? Just a thought.

Have you checked scope mounts?

It's not likely but I recently thought a rifles barrel had gone to shit and discovered my rings weren't tight. It can happen to any one.

It's not likely but I recently thought a rifles barrel had gone to shit and discovered my rings weren't tight. It can happen to any one.

I understand that alot of F Class and other benchrest barrels are torqued on lightly. Those barrel are usually straight 1.25 blanks or barely tapered which means they're heavy. The 6mm cartridges used for F class like 6x47 can't torque those heavy barrels enough to be affected by a light torque value.

In the case of a 7 SAUM on a light rifle it definitely has an effect. The CF barrel simply doesn't have the mass to counter the force on the barrel created by the 7 SAUM, it has to be torqued tight enough to counter the energy. That's my theory why the cause could be torque value.

I Maybe wrong, it happens often. I just hope it's not some delamination issue with the carbon fiber and the OP has to go through a warranty process.

Chase

In the case of a 7 SAUM on a light rifle it definitely has an effect. The CF barrel simply doesn't have the mass to counter the force on the barrel created by the 7 SAUM, it has to be torqued tight enough to counter the energy. That's my theory why the cause could be torque value.

I Maybe wrong, it happens often. I just hope it's not some delamination issue with the carbon fiber and the OP has to go through a warranty process.

Chase

300 wsm is the preferred caliber in F open around here, so plenty of torque, but I agree that it's most likely not the issue. It is easy to do and eliminate. Just like rings and bases. Next step would be bedding.

I really don't think it's any of that. Most likely just a barrel with cold bore shift and I doubt proof will do anything about it.

I really don't think it's any of that. Most likely just a barrel with cold bore shift and I doubt proof will do anything about it.

A full moa of cold bore shift from a premium barrel. Yikes, I wouldn't put up with that.300 wsm is the preferred caliber in F open around here, so plenty of torque, but I agree that it's most likely not the issue. It is easy to do and eliminate. Just like rings and bases. Next step would be bedding.

I really don't think it's any of that. Most likely just a barrel with cold bore shift and I doubt proof will do anything about it.

I'm not saying it's good. That's why you should check everything else.

I couldn’t accept that from a premium carbon fiber barrel. Proof warrantied one of my barrels for accuracy so I would report it to them. I have several CF barrels and they do not experience a cold bore shift. That barrel is stressed in some manner.

Yes sir I re torqued everything this evening and nothing was looseHave you checked scope mounts?

It's not likely but I recently thought a rifles barrel had gone to shit and discovered my rings weren't tight. It can happen to any one.

I have notHave you had someone else shoot it... just to see if it does the same thing for them? Just a thought.

Have someone else shoot it. I had a similar issue with a 300wsm, except mine was .4 mil straight down. I tried everything, including shooting 10+ rounds from a different rifle to make sure I was warmed up. Still .4 low on the first shot.I have not

Then one day I decided to completely free recoil the first group. Wouldn’t you know it, no more shift. I was just psyching myself out the whole time.

I have notHave you had someone else shoot it... just to see if it does the same thing for them? Just a thought.

thanks for the input! I will definitely try that this week when I go to the rangeHave someone else shoot it. I had a similar issue with a 300wsm, except mine was .4 mil straight down. I tried everything, including shooting 10+ rounds from a different rifle to make sure I was warmed up. Still .4 low on the first shot.

Then one day I decided to completely free recoil the first group. Wouldn’t you know it, no more shift. I was just psyching myself out the whole time.

Feniks Technologies

Premium Ammunition and Loading Supplies

Supporter

Commercial Supporter

Full Member

Minuteman

I have heard of a few doing this. Each time proof replaced the barrel. It’s very rare, but have heard it. From trusted shooters I know who got barrels replaced.

I would check everything just like everyone has suggested. And if nothing shows a problem, then contact proof.

Just be sure to test it with another barrel and optic and other such things.

FWIW, I haven’t heard of this happening lately. I want to say it was a couple years ago last one I heard about.

I would check everything just like everyone has suggested. And if nothing shows a problem, then contact proof.

Just be sure to test it with another barrel and optic and other such things.

FWIW, I haven’t heard of this happening lately. I want to say it was a couple years ago last one I heard about.

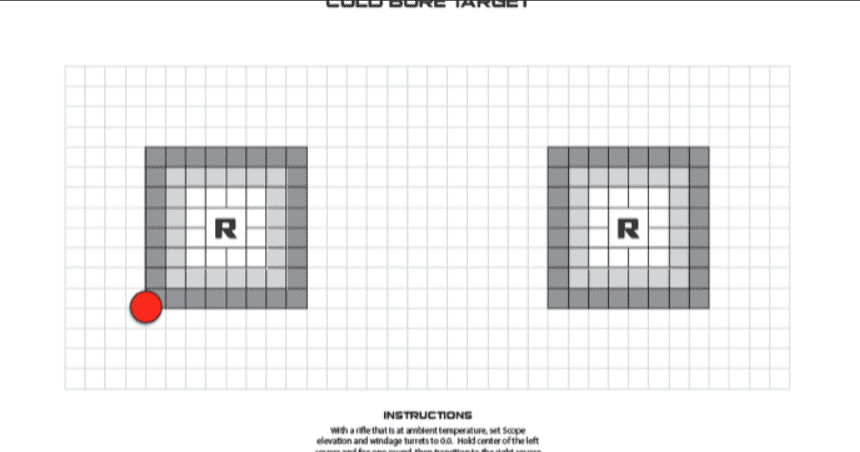

I stripped the rifle completely apart with the exception of taking the barrel off the action and re torqued everything. My cold bore shot moved from low to high. The barrel is not making contact at all it’s in a phenix greyboe stock. Do y’all think it’s a bedding issue with the action? This is a pic of my groups at 300 yards green is the 3rd group I shot out of a warm barrelI have heard of a few doing this. Each time proof replaced the barrel. It’s very rare, but have heard it. From trusted shooters I know who got barrels replaced.

I would check everything just like everyone has suggested. And if nothing shows a problem, then contact proof.

Just be sure to test it with another barrel and optic and other such things.

FWIW, I haven’t heard of this happening lately. I want to say it was a couple years ago last one I heard about.

Attachments

I stripped the rifle completely apart with the exception of taking the barrel off the action and re torqued everything. My cold bore shot moved from low to high. The barrel is not making contact at all it’s in a phenix greyboe stock. Do y’all think it’s a bedding issue with the action? This is a pic of my groups at 300 yards green is the 3rd group I shot out of a warm barrelI've shot hand tight CF barrels and not had a zero shift. I think I have one barrel that's torqued on harder that 40ftlbs and I haven't shot it in 5 years. I just melted my AI out of the chassis, took the scope off, completely disassembled the trigger, action down to individual components, re-bedded the action in the chassis and assembled the rifle. It was .2mrad high when I shot it.

Don't accept a cold bore. It's your rifles mechanical cry for help.

It's not barrel torque

How did the rifle shoot before that barrel?

Is the action bedded?

Have you shot a 10rd dot drill with it?

Attachments

How are you torquing the action screws? Snug & straight to 65 or in steps 15-35-65. Which screw are you torquing first front or back?

That shift down to up. It kinda seams like maybe the first time you torqued the front first & on reassembly reversed the order.

Either way I'm thinking this looks like a stock/bedding issue.

That shift down to up. It kinda seams like maybe the first time you torqued the front first & on reassembly reversed the order.

Either way I'm thinking this looks like a stock/bedding issue.

Try torquing the front screw to 65 and the back to 45 make sure you do the front screw first. Make sure the tang is seated properly before to tighten everything up

I did front back front back in increments of 20 till both where at 65How are you torquing the action screws? Snug & straight to 65 or in steps 15-35-65. Which screw are you torquing first front or back?

That shift down to up. It kinda seams like maybe the first time you torqued the front first & on reassembly reversed the order.

Either way I'm thinking this looks like a stock/bedding issue.

I used to have a chrome moly 308 parkerhale barrel that after cleaning used to shoot 4moa low for the first shot. But if I left the rifle dirty for a week that first shot was always with the rest of the group, now that barrel was a real hummer ! And .5 moa was normal for well over 1500 rounds but then it started throwing shots, I believe that the barrel needed to be fouled to shoot, and maybe your one is the same, just look at some rimfire barrels and fouling.

But looking at your latest pictures it could be bedding and also the last and most important thing that people often miss is loose barrel threads !!! The barrel should screw into the action with virtually no sideways movement of the barrel at all. This is how the very best benchrest target rifles are built,now you can have exceptional rifles with a slightly loose barrel that will shoot but most will change their poi as they heat up.

But looking at your latest pictures it could be bedding and also the last and most important thing that people often miss is loose barrel threads !!! The barrel should screw into the action with virtually no sideways movement of the barrel at all. This is how the very best benchrest target rifles are built,now you can have exceptional rifles with a slightly loose barrel that will shoot but most will change their poi as they heat up.

Last edited:

The high and low 1st shot impacts tell me there is an issue with the bedding between tear downs. It started out throwing a high 1st shot flyer, you tore in down and put it back together and now it's throwing a low 1st shot flyer. This would indicate to me that it does not repeat its bedding setup. Being able to repeat is critical. Buy some Jarrows inletting black or some Prussian blue and brush it on your bedding areas and torque it into the stock. Tear it down and inspect the inlet for contact. You want your contact at the front and rear screws and relieved between the screws, center of receiver. Pay close attention for print marking on the tops of the pillars, if the tops of the pillars are proud the receiver is teetering on those slightly too tall pillars. You want to achieve a good print at the front and rear screws. Inspect the recoil lug pocket, both bottom and sides of the pocket. Also inspect the top corner of the recoil lug pocket where it intersects with the recoil lug corner on the receiver, a nice chamfer on the top back corner of the lug pocket ensures a small amount of tolerance for the inside corner of the recoil lug on the receiver. If its hung up on that corner then the recoil lug on the receiver can't sit all the way back on the recoil face of the stock and receiver. Do the same printing technique for the bottom metal, making small changes to achieve proper uniform contact in the inlet. Repeat this process as it will take a couple fittings and inspections to get it perfect. Do all of this with the optic removed as it is essentially in the way for this process. Remove your printing agent with brake cleaner on a shop towel. Ensure that the magazine box floats, it only needs a small amount of vertical travel between the receiver and bottom metal .020 will do. Ensure that no part of the trigger is in contact with the bottom metal and or stock, if so, correct it. Ensure that the action screws are in no way in contact with the interior of the pillars. With all this sorted out, torque the B/A into the stock, 45 to 65 IP. Mount your scope rings in the positions you intend to use, with the correct diameter bar lap the scope rings with 120 thru 240gt lapping compound, what you are looking for is to remove the high spots in the rings and attain good uniform contact, alignment and surface area. The Greyboe stock is an injected mass produced product as many are and in no way are perfect. final fitting for best results may be required. Knowing that the barreled action is correctly bedded is better than thinking/assuming that it is. With this work correctly executed you can then make the assessment of barrel quality. The barrel shows good potential as it puts 2 and 3 in there, at this point I don't think its the barrel. However, checking how the barrel infaces with the receiver could also be inspected. A simple and quick way to do this is use a candle or smoke lamp to apply soot to the receiver face, screw the barrel and receiver together, just by hand, what you are looking for is a nice full print the full circumference of the barrel diameter to the receiver face and any interruptions that could be preventing proper receiver face contact with the barrel, pay close attention to the corner at the barrel shoulder, barrels that hang up in the corner at the shoulder will exhibit flyers. I do realize this has turned into a wall of text and if you've read this far then you may have gained some knowledge as to why your rifle is producing that 1st shot flyer. In my 35 years of rifle work for a living I've learned that the small details correctly executed make for very satisfying results. Buying a bunch of parts and screwing it all together does not guarantee a supremely accurate set up. You have decent components, ensuring they are together perfectly, not close or good enough, I mean perfectly. Only then can you realize the true performance of that rifle system and your ability as a marksman/shooter. I would say " good luck" but supreme rifle accuracy is .5% luck and 99.5% having it perfect. Make perfect happen.

That is a truly excellent large bite of advice and experience. Not the OP, but applicable to many of us. Thank you.

Similar threads

- Replies

- 4

- Views

- 427