Hello everyone.

I am currently trying to resolve some issues I am having with my Proof Research prefit carbon fiber RPR barrel I ordered. It is chambered in 6.5 creedmoor with a 1:7.5 twist. After installing the barrel in my RPR it has been shooting terribly. Consistently shooting 2moa at 100 yards. My factory barrel held about .4 moa at 100 yards. I was hoping to get a second opinion before sending the barrel in for warranty work. Below is the conversation I have been having with the factory. The blue text is the response I am getting back from them. I have found what appears to be an issue with the lands described below. Their lead engineer is claiming that there are no major issues with the bore scope video.

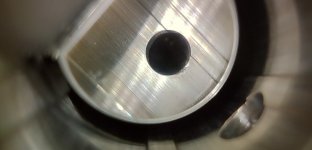

I have attached the videos below. I should add they have given me an RMA number. For the more experienced guys here, do you see anything wrong with the bore video?

Thank You

Hello

I ordered a proof research ruger precision rifle prefit barrel 6.5 creedmoor 24" carbon fiber barrel on march 29.

After installing the barrel and shooting I have discovered that it was shooting terribly. The accuracy was considerably worse than the stock barrel.

Upon inspection I discovered that the bullet no matter how far it is seated out of the cartridge will not make contact with the lands.

It is currently shooting about 2 moa at 100 yards.

Please let me know what the next steps are to resolve this issue.

Ryan –

What ammo are you running? Factory or hand loads?

Hand loads. Berger 140 grain. I have also tried hornady factory with even worse performance.

I bore scoped the barrel and compared it to the factory. In the factory barrel the lands ramp down and terminate at the same line that spans the internal circumference of the barrel. On the proof barrel there is no ramp down for the lands. They appear to be sheared off. Moreover they aren't sheared along the same internal line. Where they are sheered the edge looks like hundreds of small needles. Not a clean cut at all.

It appears to me that a throat reamer was never used on it. I am attaching 2 videos. One of my factory barrel with 250 rounds through it that holds .4 to .5 moa at 100 yards.

https://www.amazon.com/photos/shared/WJDc7AC_TceEU0JnppVLNQ.xUfDCRih7HzmCMmw0WRQLv

The second video is of the proof barrel that is struggling to hold 2 moa at 100 yards.

https://www.amazon.com/photos/shared/ouzvpwc4TAO1UfWTXYdp8w.JxosDcN2Dl52tfrr8TKdkA

Never seen lands deformed like that. This barrel has less than 40 rounds through it.

Ryan –

I got with our lead engineer and here is what I got back:

I don’t see any major issues in his bore scope video.

The one thing that sticks out is that he states he can’t seat the bullets to the lands although that’s not necessary for good accuracy. What is the cartridge overall length he is running? It’s possible that the barrel was installed with excessive headspace. Did he check it with headspace gauges? Can he measure the change in the cartridge shoulder position before and after firing with a new case? How much does it change? Has he had any light primer strikes after the barrel was installed?

I would expect our barrel to match the accuracy of his factory barrel.

I dont seat to the lands. I use an oal guage to measure the distance to the lands and then back off by 1 hundredth.

The measurement to the lands in the proof barrel without being installed is 2.2740"

This is taken with a pair of Mitutoyo calipers and hornaday bullet comparator using the 5-26 adapter for the 6.5 creedmoor.

The measurement on the factory barrel is 2.0335"

That is .24" off. Almost a quarter of an inch. Attached is a picture of what each looks like compared to a factory bullet on the right side.

The smaller bullet pic on the left is the factory barrel.

The larger is the proof barrel.

The third picture is showing the bullet seated in the proof barrel compared to the magazine.

I am currently trying to resolve some issues I am having with my Proof Research prefit carbon fiber RPR barrel I ordered. It is chambered in 6.5 creedmoor with a 1:7.5 twist. After installing the barrel in my RPR it has been shooting terribly. Consistently shooting 2moa at 100 yards. My factory barrel held about .4 moa at 100 yards. I was hoping to get a second opinion before sending the barrel in for warranty work. Below is the conversation I have been having with the factory. The blue text is the response I am getting back from them. I have found what appears to be an issue with the lands described below. Their lead engineer is claiming that there are no major issues with the bore scope video.

I have attached the videos below. I should add they have given me an RMA number. For the more experienced guys here, do you see anything wrong with the bore video?

Thank You

Hello

I ordered a proof research ruger precision rifle prefit barrel 6.5 creedmoor 24" carbon fiber barrel on march 29.

After installing the barrel and shooting I have discovered that it was shooting terribly. The accuracy was considerably worse than the stock barrel.

Upon inspection I discovered that the bullet no matter how far it is seated out of the cartridge will not make contact with the lands.

It is currently shooting about 2 moa at 100 yards.

Please let me know what the next steps are to resolve this issue.

Ryan –

What ammo are you running? Factory or hand loads?

Hand loads. Berger 140 grain. I have also tried hornady factory with even worse performance.

I bore scoped the barrel and compared it to the factory. In the factory barrel the lands ramp down and terminate at the same line that spans the internal circumference of the barrel. On the proof barrel there is no ramp down for the lands. They appear to be sheared off. Moreover they aren't sheared along the same internal line. Where they are sheered the edge looks like hundreds of small needles. Not a clean cut at all.

It appears to me that a throat reamer was never used on it. I am attaching 2 videos. One of my factory barrel with 250 rounds through it that holds .4 to .5 moa at 100 yards.

https://www.amazon.com/photos/shared/WJDc7AC_TceEU0JnppVLNQ.xUfDCRih7HzmCMmw0WRQLv

The second video is of the proof barrel that is struggling to hold 2 moa at 100 yards.

https://www.amazon.com/photos/shared/ouzvpwc4TAO1UfWTXYdp8w.JxosDcN2Dl52tfrr8TKdkA

Never seen lands deformed like that. This barrel has less than 40 rounds through it.

Ryan –

I got with our lead engineer and here is what I got back:

I don’t see any major issues in his bore scope video.

The one thing that sticks out is that he states he can’t seat the bullets to the lands although that’s not necessary for good accuracy. What is the cartridge overall length he is running? It’s possible that the barrel was installed with excessive headspace. Did he check it with headspace gauges? Can he measure the change in the cartridge shoulder position before and after firing with a new case? How much does it change? Has he had any light primer strikes after the barrel was installed?

I would expect our barrel to match the accuracy of his factory barrel.

I dont seat to the lands. I use an oal guage to measure the distance to the lands and then back off by 1 hundredth.

The measurement to the lands in the proof barrel without being installed is 2.2740"

This is taken with a pair of Mitutoyo calipers and hornaday bullet comparator using the 5-26 adapter for the 6.5 creedmoor.

The measurement on the factory barrel is 2.0335"

That is .24" off. Almost a quarter of an inch. Attached is a picture of what each looks like compared to a factory bullet on the right side.

The smaller bullet pic on the left is the factory barrel.

The larger is the proof barrel.

The third picture is showing the bullet seated in the proof barrel compared to the magazine.