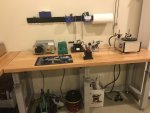

I'm planning on moving my reloading setup from it's current worn out cracked wooden bench to something new.

I was wondering if there's a commonly available easy solution? I've done a little bit of snooping around and I'm not coming up with much. I just want something stout with a low center of gravity (obviously I can help this with bullets). May just need to throw a half inch steel plate on top of something lighter

I was wondering if there's a commonly available easy solution? I've done a little bit of snooping around and I'm not coming up with much. I just want something stout with a low center of gravity (obviously I can help this with bullets). May just need to throw a half inch steel plate on top of something lighter