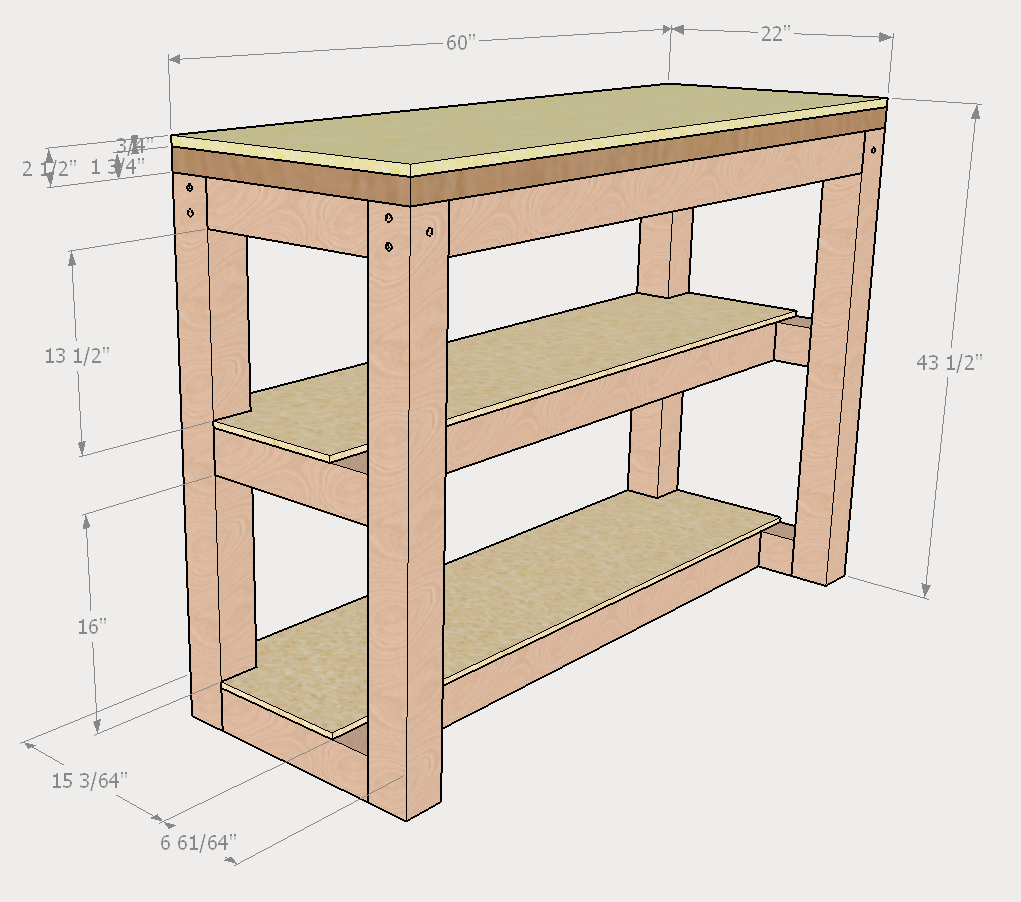

Hey folks, first post here, I have seen some pretty nice bench builds and some improvised benches from Harbor Freight. I want to build my own so after scouring the forum I came up with a design I think will work well. I am planning to build the base out of 4x4 lumber. The base pieces will be assembled with 3/8" x 7" lag screws. For the top I plan on a combination of a 1.75" solid core door and .75" MDF for a total thickness of 2.5". I stepped the bottom shelves back about 6' so I can get my knees under the table a bit to sit comfortably. I will be mounting my Lyman T-Mag 2 press that sits on a 9" riser base from inline fabrication.

I am new to reloading and this will be my first bench built for that purpose. Any reasons why this bench wouldn't work? Any considerations I may have not thought of?

I am new to reloading and this will be my first bench built for that purpose. Any reasons why this bench wouldn't work? Any considerations I may have not thought of?