Has anybody used one of these tools mentioned by Larry Medler in his reloading tips. Raise this because ethe rims seem to be an issue on some second hand brass I have bought. Seems a nifty tool.

Uniform the extractor grove

Now here is a step the most bench rest guys don’t even do. Re-cut the extractor grove on the cartridge base. I saw this in one of the articles in Precision Shooting a few years back and give a copy to two friends, which both just happen to be machinist types. Low and behold I got two of these things. Never have told them that I have two. Both think I am using the one they made. Tool works great and the biggest difference I have noticed after re-cutting all the extractor grove happens while seating the primers. The shell holder on my Lee primer-seating tool is very discriminating towards cartridges, which have an ever so slightly larger diameter or damaged extractor grove. Before re-cutting the extractor grove on other brass, I would notice every now and then a case that would not slide into the shell holder very easily. It would hang up on something. But after re-cutting the extractor groves, they all slip into the Lee priming tool shell holder with the greatest of ease. Now when I priming some 45ACP I get some cases that stick in the Lee Priming Tool on burred and damaged rims.

The re-cutting of the extractor grove also kisses the web or rim. This makes all of the rims the same. All of this should make things better when the bolt closes and the extractor slips into the grove. I have noticed less or no brass shavings in the bolt face and extractor after re-cutting the cartridges extractor groves. Can’t say that my (standing) groups are any smaller, but this step really makes me feel good so it must help me shoot better.

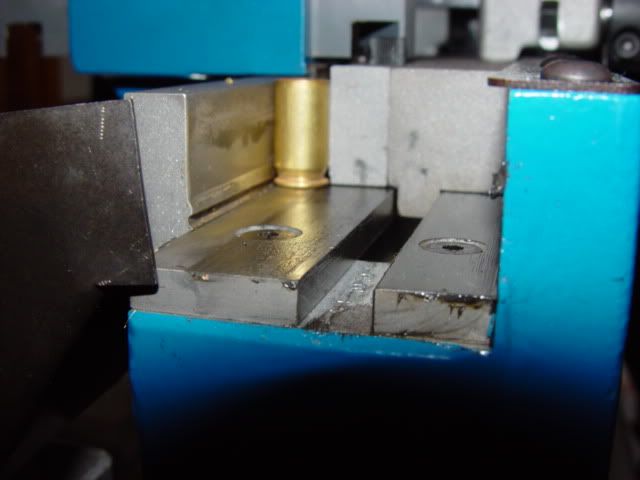

The case holder in the picture was made from a small piece of oak. A hole was drilled into the oak, which the case shoulder would get stuck if pushed. Actually I drilled the hole in the piece of oak and with a little help from some epoxy, formed a hole that the case could be press into and it would hold the case during the re-cutting process. After re-cutting, I put a ¼ in. steel rod into the case and tap it off the oak holder.

Back to Case Preparation Index

Uniform the extractor grove

Now here is a step the most bench rest guys don’t even do. Re-cut the extractor grove on the cartridge base. I saw this in one of the articles in Precision Shooting a few years back and give a copy to two friends, which both just happen to be machinist types. Low and behold I got two of these things. Never have told them that I have two. Both think I am using the one they made. Tool works great and the biggest difference I have noticed after re-cutting all the extractor grove happens while seating the primers. The shell holder on my Lee primer-seating tool is very discriminating towards cartridges, which have an ever so slightly larger diameter or damaged extractor grove. Before re-cutting the extractor grove on other brass, I would notice every now and then a case that would not slide into the shell holder very easily. It would hang up on something. But after re-cutting the extractor groves, they all slip into the Lee priming tool shell holder with the greatest of ease. Now when I priming some 45ACP I get some cases that stick in the Lee Priming Tool on burred and damaged rims.

The re-cutting of the extractor grove also kisses the web or rim. This makes all of the rims the same. All of this should make things better when the bolt closes and the extractor slips into the grove. I have noticed less or no brass shavings in the bolt face and extractor after re-cutting the cartridges extractor groves. Can’t say that my (standing) groups are any smaller, but this step really makes me feel good so it must help me shoot better.

The case holder in the picture was made from a small piece of oak. A hole was drilled into the oak, which the case shoulder would get stuck if pushed. Actually I drilled the hole in the piece of oak and with a little help from some epoxy, formed a hole that the case could be press into and it would hold the case during the re-cutting process. After re-cutting, I put a ¼ in. steel rod into the case and tap it off the oak holder.

Back to Case Preparation Index