I just bedded my bottom metal on my B series Rem 700 BDL.

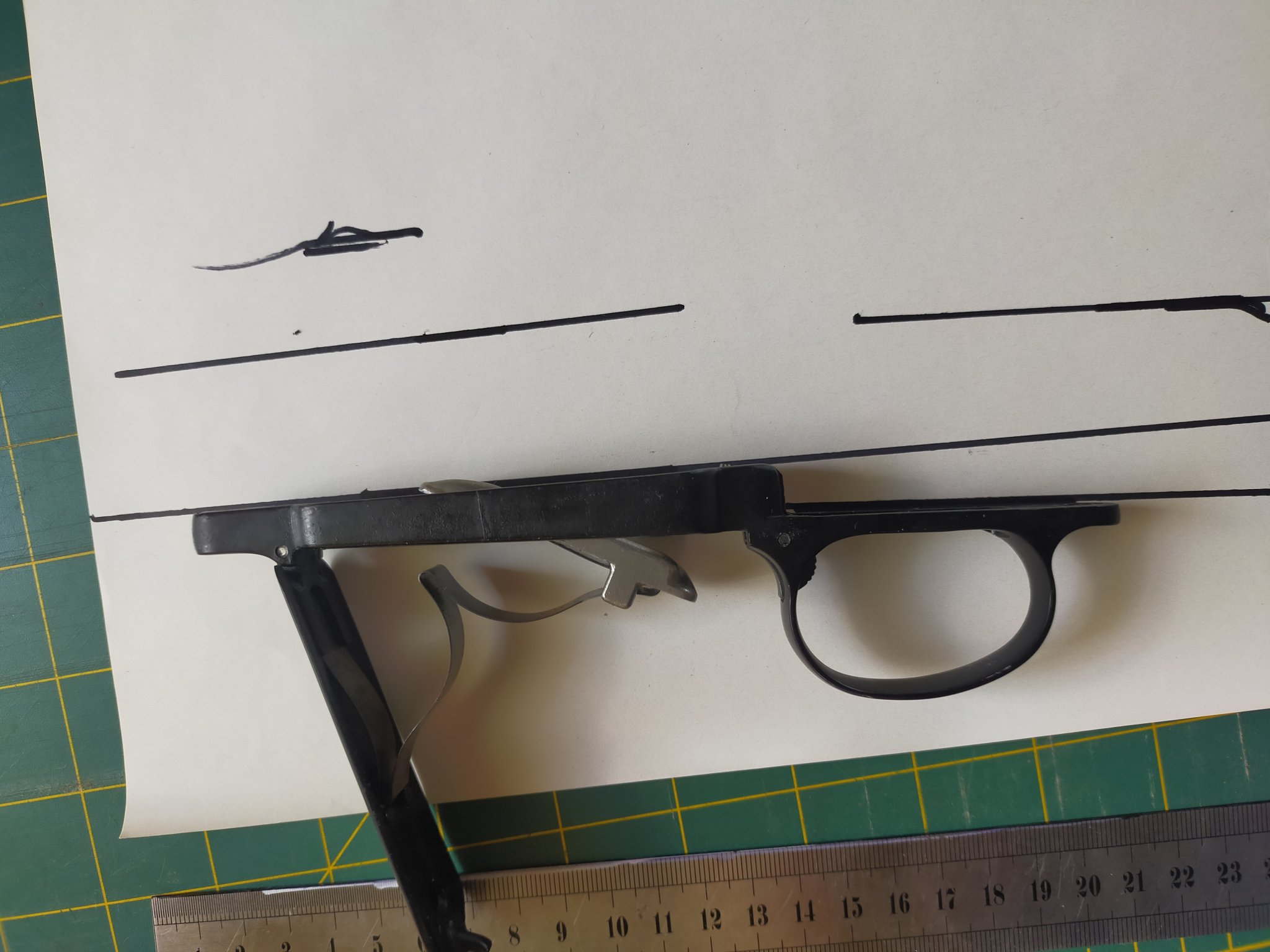

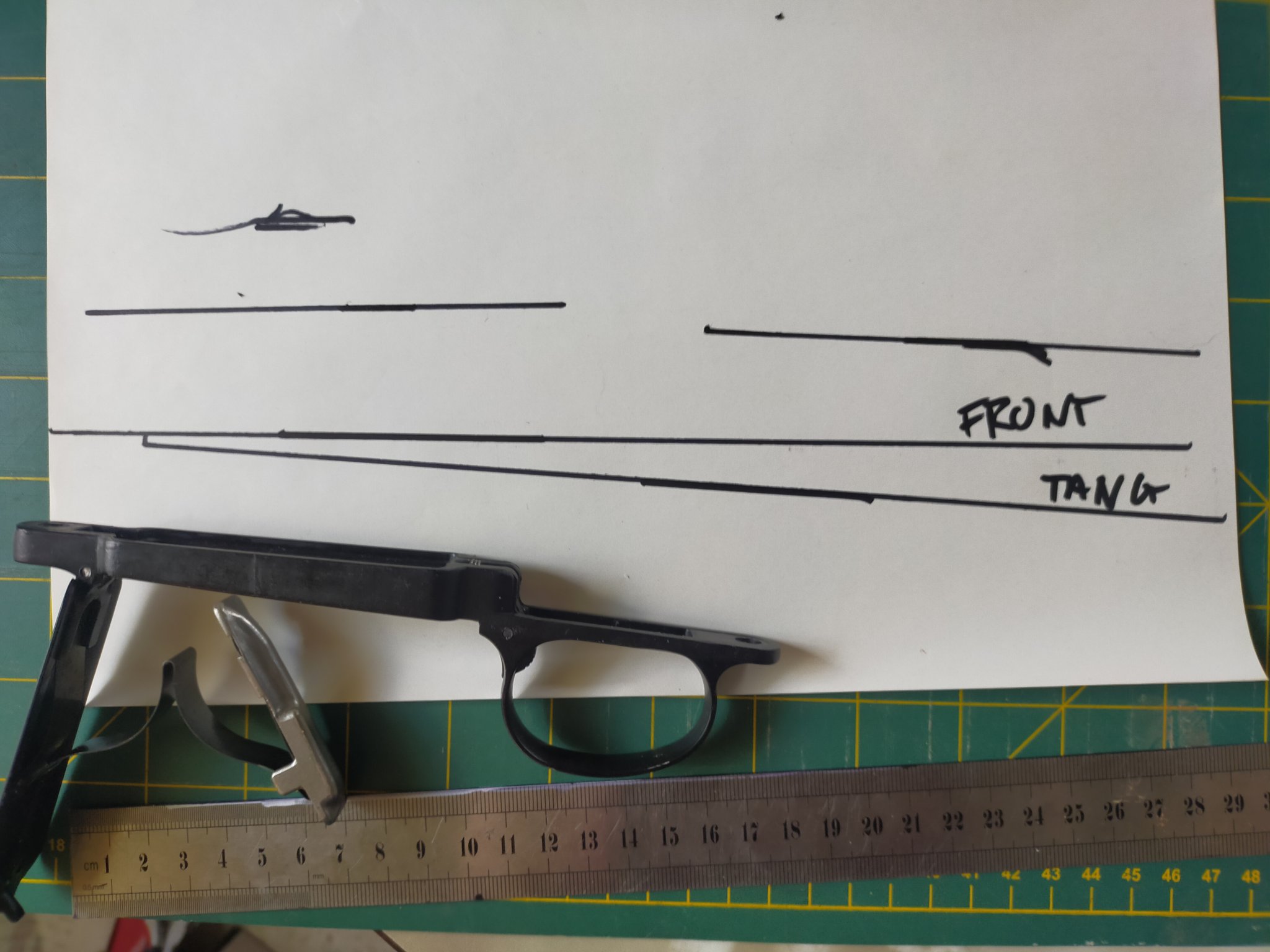

It was rocking between front and back (tang) slightly...with a gap about a matchstick thick at back.

Now....tang screw half fills hole...might get a longer replacement.

But...what caught my eye was that the action screw recesses are not parallel.

This means that tang end tightening flexes the floor plate, prior to bedding...when screws are tightened down!

Is this normal?

If so..

What's the idea behind it...

Thanks.

It was rocking between front and back (tang) slightly...with a gap about a matchstick thick at back.

Now....tang screw half fills hole...might get a longer replacement.

But...what caught my eye was that the action screw recesses are not parallel.

This means that tang end tightening flexes the floor plate, prior to bedding...when screws are tightened down!

Is this normal?

If so..

What's the idea behind it...

Thanks.