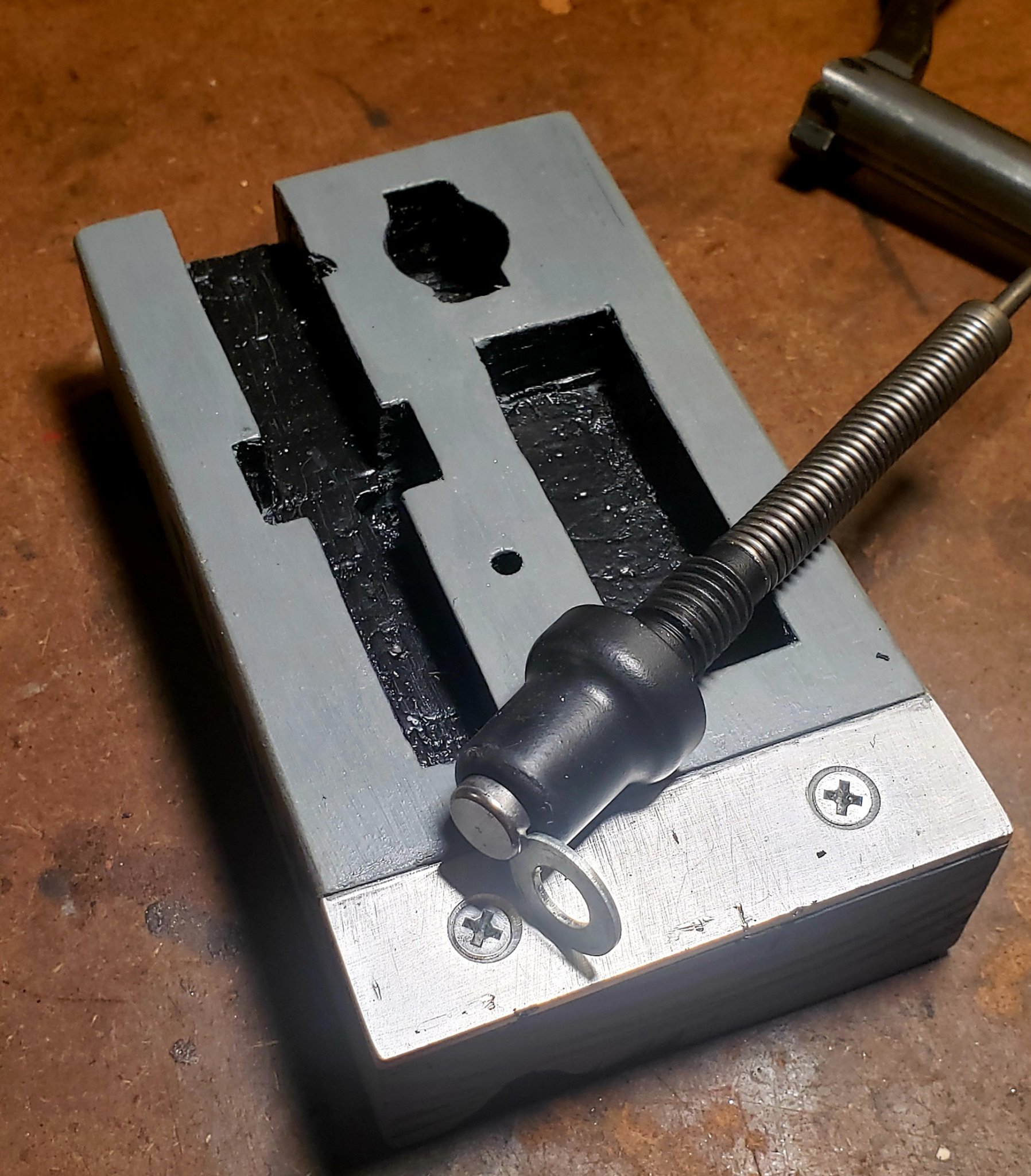

Originally I posted one of these in the M24 thread based loosely on a diagram of a "maintenance block" in the back of the M24 TM but I added some features and this is the Mod 1 version . Except for the piece of brass, everything came from the hardware store, a piece of 2x4, nylon spacer, washer, aluminum, wood screws, that's about it. The various pockets were done using Forstner bits and a chisel mostly and the v-notches done with a saw and cleaned up with wood block and sandpaper.

The parts tray also serves to store any accessory tools needed for disassembly and the foam keeps everything in place.

The aluminum edge is for pulling the cocking piece back so a coin, washer, or dog tag can be slipped into the notch to remove the firing pin assembly.

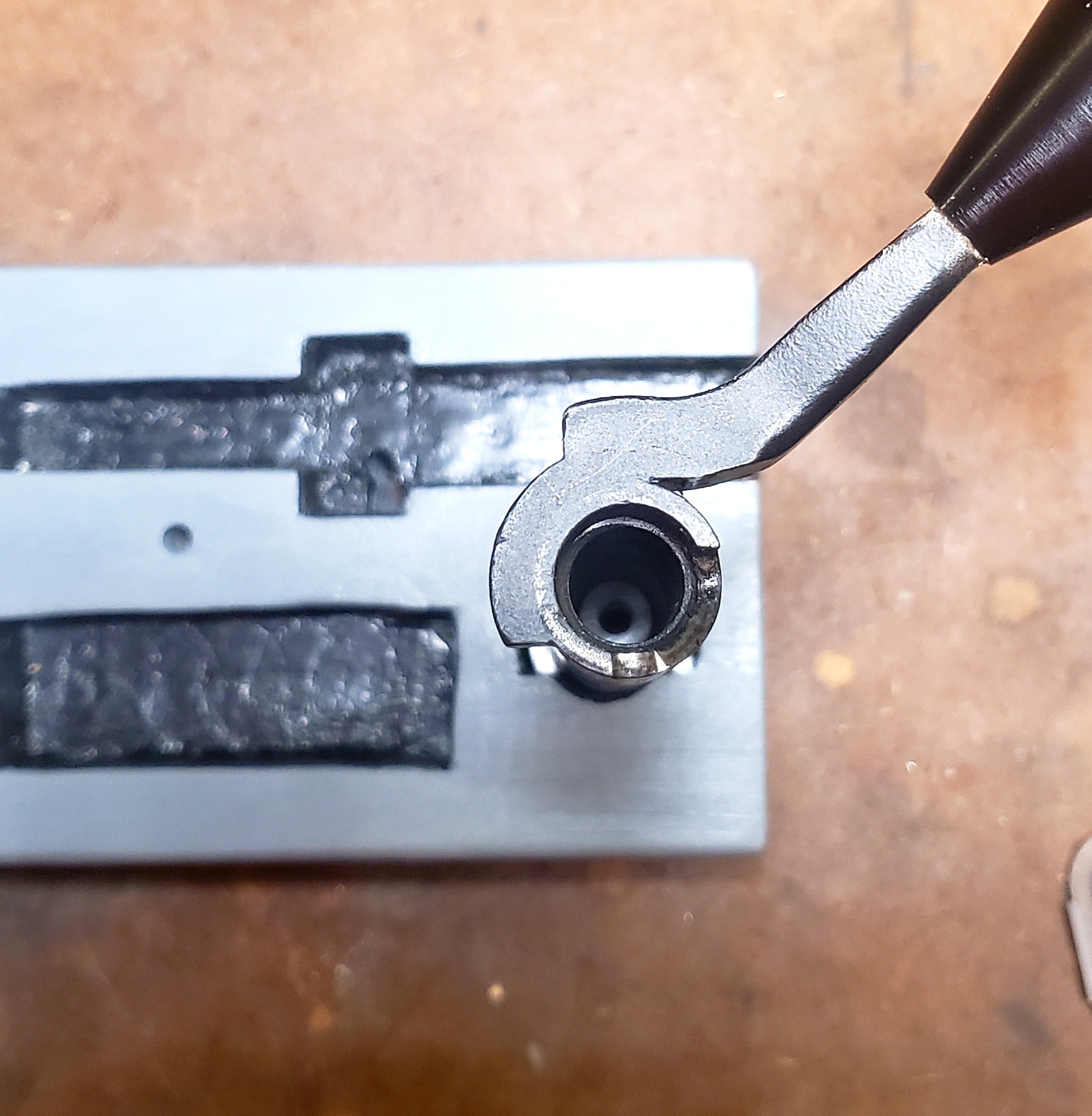

A .375" OD X .750 OAL nylon spacer goes into the bolt body and the FPA reinserted and screwed in until the retaining pin is visible and can be removed. The bolt shroud is then unscrewed and the FPA is disassembled to replace the firing pin and/or firing pin spring.

The bolt shaped notch is sized so that a fired case can be held in place to compress the ejector spring and the pin knocked out for removal. I tested the notch with a Springfield Waypoint, Remington 700, and Bergara B14 bolt.

The bottom side was notched and drilled so that I could lay a SA receiver on it and punch out the trigger pins.

So, that's that, admittedly it's not the best craftsmanship but better than the last one so that counts for something lol.

Cheers

The parts tray also serves to store any accessory tools needed for disassembly and the foam keeps everything in place.

The aluminum edge is for pulling the cocking piece back so a coin, washer, or dog tag can be slipped into the notch to remove the firing pin assembly.

A .375" OD X .750 OAL nylon spacer goes into the bolt body and the FPA reinserted and screwed in until the retaining pin is visible and can be removed. The bolt shroud is then unscrewed and the FPA is disassembled to replace the firing pin and/or firing pin spring.

The bolt shaped notch is sized so that a fired case can be held in place to compress the ejector spring and the pin knocked out for removal. I tested the notch with a Springfield Waypoint, Remington 700, and Bergara B14 bolt.

The bottom side was notched and drilled so that I could lay a SA receiver on it and punch out the trigger pins.

So, that's that, admittedly it's not the best craftsmanship but better than the last one so that counts for something lol.

Cheers