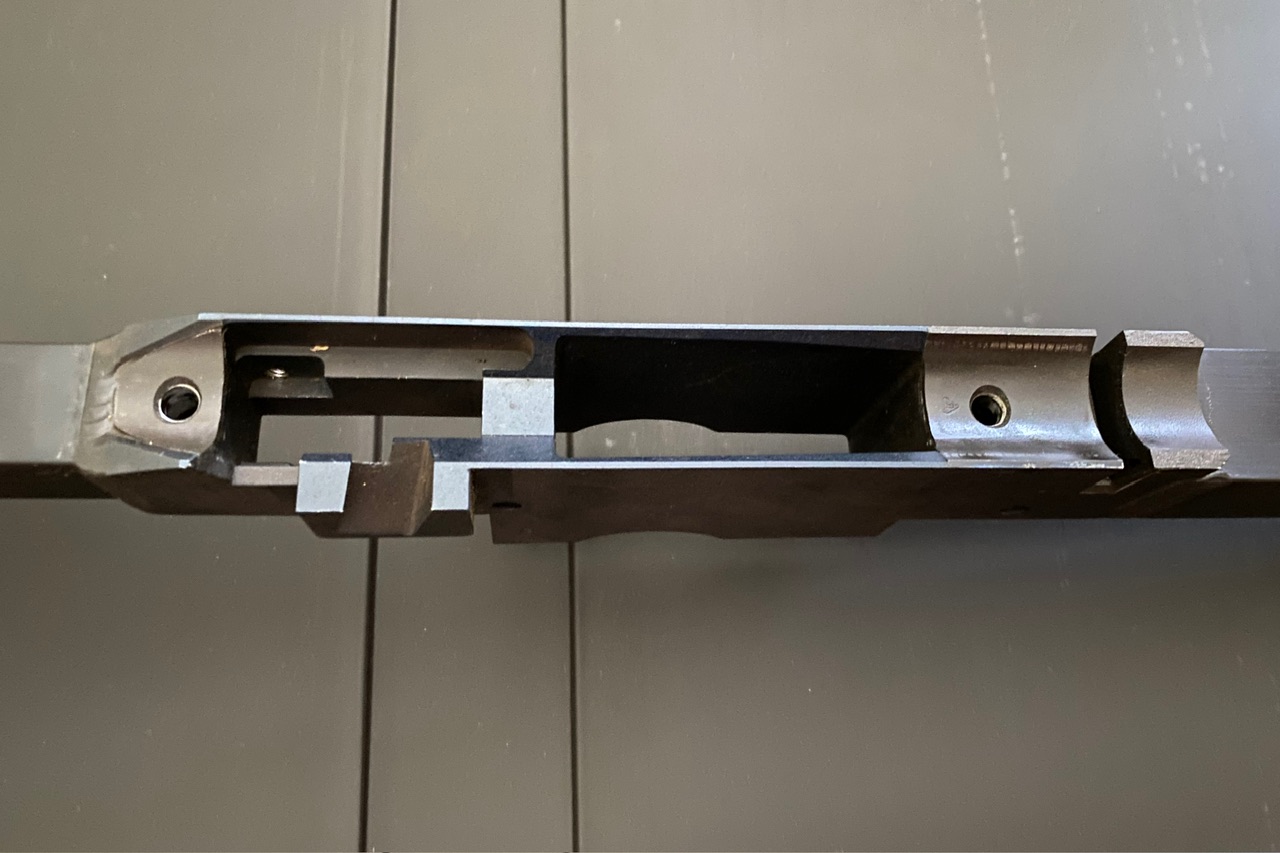

Picked up this AICS recently and it is bedded to the previous action. Anyone know someone that can professionally remove the bedding and get the chassis back to its original action frame? Will pay for the service, of course. Thanks in advance!

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Removing Bedding From AICS Chassis

- Thread starter kft101

- Start date

Do you know what they've bedded it with? I've removed JB Weld bedding from an aluminum bedding block using a soldering iron with a chisel tip after I let it heat up really good, it rolled the bedding material right off. Mask up and wear eye protection.

The person I got the AICS from is not sure. Maybe marinetex.Do you know what they've bedded it with? I've removed JB Weld bedding from an aluminum bedding block using a soldering iron with a chisel tip after I let it heat up really good, it rolled the bedding material right off. Mask up and wear eye protection.

Regardless, I live in a tiny place in a big city, so best to send it off to a professional shop that can do it right. Lol

I think most epoxy will come off with heat. If you have a heat gun, you could try it and see if it softens up. It seems to be how most people separate the bedding on factory AI rifles.

If this were me:

I'd find a slug of steel with a similar diameter to the receiver. Warm that bugger up with a torch until it starts to smoke/show some tempering color change (400-600 degrees). Grab it with some slip joint pliers and just set it on the bedded area. I'd strip the chassis down of all its plastic first.

When the thing starts to smell like a nail salon in the mall, you're in business. Remove the slug and tap on the resin with a ball peen hammer. The residual resin will peen and fall off. Once it cools a bit, scrape the remainder with a stick of plastic ground to a sharp edge.

Now for the hard part: Whoever bedded this should have scuffed the surfaces with a file, sanding roll, carbide burr, etc... That is a bell you can't really unring. Assuming that's the case, you are now left with a problem to solve, and the only practical solution is to make a new casting of your receiver tang.

FWIW:

When bedding the tang of AI stuff was all the rage ten or so years ago, I looked for an alternative solution as I didn't care much for how they turned out. What I did was a little more extreme, but it proved to work well.

Another thing we tried a couple of times was 3D surface machining the alloy chassis to allow the receiver to be fully supported. The issue here is the cascading effects it has on the system as a whole. Magazine guides, release levers, trigger assemblies, safety selector switches, bolt handles, lug wells -basically everything must be moved down as well. It proved to be cost-prohibitive as it was a great deal of work.

EDIT :

After thinking about this a little more, OP, the solution for removing the resin is super easy. Put all that heat gun/torch stuff away. Just send us the aluminum chassis piece completely stripped down. 10minutes in my new blast cabinet (a $40k positive feed monster) will strip that thing down to the bare metal. From there, we can Cerakote it Graphite Black or send it out to be anodized.

It won't solve the issue of someone scuffing up the surface, but it'll remove every trace of the bedding material. If you are planning to make a new receiver casting, it'll at least give you a virgin canvas to work from.

Good luck.

I'd find a slug of steel with a similar diameter to the receiver. Warm that bugger up with a torch until it starts to smoke/show some tempering color change (400-600 degrees). Grab it with some slip joint pliers and just set it on the bedded area. I'd strip the chassis down of all its plastic first.

When the thing starts to smell like a nail salon in the mall, you're in business. Remove the slug and tap on the resin with a ball peen hammer. The residual resin will peen and fall off. Once it cools a bit, scrape the remainder with a stick of plastic ground to a sharp edge.

Now for the hard part: Whoever bedded this should have scuffed the surfaces with a file, sanding roll, carbide burr, etc... That is a bell you can't really unring. Assuming that's the case, you are now left with a problem to solve, and the only practical solution is to make a new casting of your receiver tang.

FWIW:

When bedding the tang of AI stuff was all the rage ten or so years ago, I looked for an alternative solution as I didn't care much for how they turned out. What I did was a little more extreme, but it proved to work well.

- Drill and tap the rear guard screw hole from the top to 1/2-20.

- Turn/thread a stick of brass to the same thread pitch and install it into the chassis so that it looks like a golden stump poking out the back half of the register.

- Drill the center to accept the guard screw.

- I made a tool with a .675 radius on the bottom. I'd make incremental cuts with it until the "stump" was whittled down far enough to allow the receiver to simultaneously purchase the flanks and the saddle created by the brass slug. I did this using high spot indicating paste.

Another thing we tried a couple of times was 3D surface machining the alloy chassis to allow the receiver to be fully supported. The issue here is the cascading effects it has on the system as a whole. Magazine guides, release levers, trigger assemblies, safety selector switches, bolt handles, lug wells -basically everything must be moved down as well. It proved to be cost-prohibitive as it was a great deal of work.

EDIT :

After thinking about this a little more, OP, the solution for removing the resin is super easy. Put all that heat gun/torch stuff away. Just send us the aluminum chassis piece completely stripped down. 10minutes in my new blast cabinet (a $40k positive feed monster) will strip that thing down to the bare metal. From there, we can Cerakote it Graphite Black or send it out to be anodized.

It won't solve the issue of someone scuffing up the surface, but it'll remove every trace of the bedding material. If you are planning to make a new receiver casting, it'll at least give you a virgin canvas to work from.

Good luck.

Last edited:

Try some Zip Strip gel it will eat most epoxies. I haven't had it damage Cerakote but it will remove paint. You can apply it with a cotton swab and let it work awhile then wipe it off with a paper towel. It will take several applications to completely remove the compound. You can use a sharpened popsicle stick to scrape on it when the Zip Strip softens it up. All the supplies should be available at most hardware stores. That's the least invasive method I've found for removing bedding.

@FisherT&C Thanks for this recommendation. I’ve read this recommended on other sites/posts with the same question.Try some Zip Strip gel it will eat most epoxies. I haven't had it damage Cerakote but it will remove paint. You can apply it with a cotton swab and let it work awhile then wipe it off with a paper towel. It will take several applications to completely remove the compound. You can use a sharpened popsicle stick to scrape on it when the Zip Strip softens it up. All the supplies should be available at most hardware stores. That's the least invasive method I've found for removing bedding.

Does it need to be Zip Strip, or should other paint/varnish/epoxy removers like Klean-Strip or Citristrip paste work as well? Can’t seem to find any Zip Strip brand gel in stock anywhere near me.

Those should work. Use the gel version it's a lot easier to work with.@FisherT&C Thanks for this recommendation. I’ve read this recommended on other sites/posts with the same question.

Does it need to be Zip Strip, or should other paint/varnish/epoxy removers like Klean-Strip or Citristrip paste work as well? Can’t seem to find any Zip Strip brand gel in stock anywhere near me.

Similar threads

- Replies

- 9

- Views

- 823

- Replies

- 2

- Views

- 521