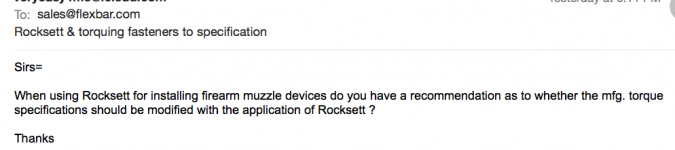

I can't find this specific answer so... I'm about to mount my first muzzle brake using rocksett. Does the addition of rocksett add or take away torque from my initial dry setup with just the shims?

Put another way, will the brake turn more or less to achieve the same torque value? I'm having a very frustrating time finding the correct shim combo and don't want to be back to square one upon adding rocksett.

Put another way, will the brake turn more or less to achieve the same torque value? I'm having a very frustrating time finding the correct shim combo and don't want to be back to square one upon adding rocksett.