I tested effect of different torque values in the RPRF over the weekend. I read some other post (not sure if on here or elsewhere) that found no appreciable difference in torque tuning, but my test seemed to indicate otherwise.

Setup:

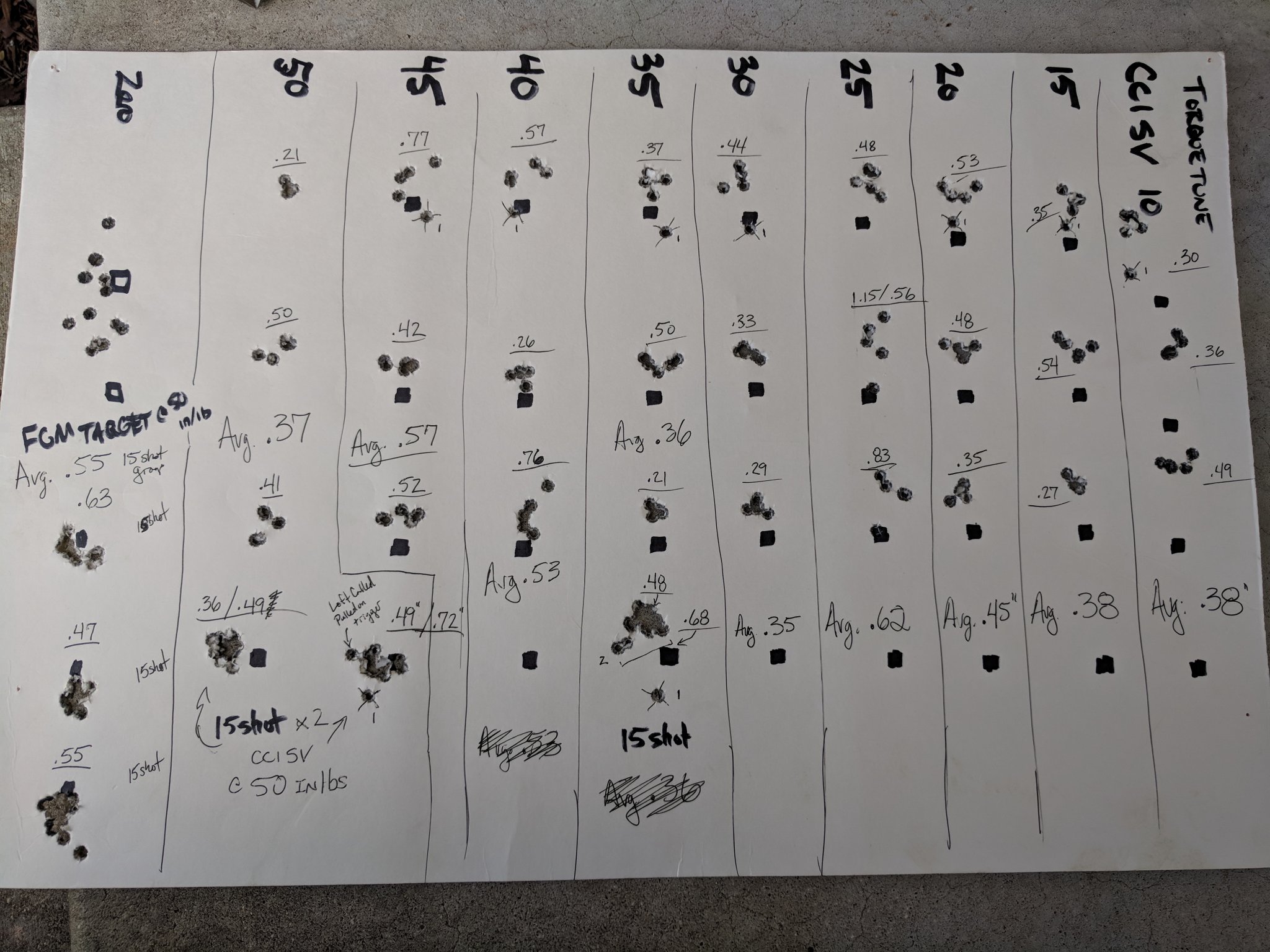

Barrel was cleaned thoroughly prior to test and 50 rounds fired to settle in barrel before shooting groups and torque tuning. Results below, picture at bottom. Shot from right to left (10inlb to 50inlb).

Note that I pulled the first shot from most groups as it drops 1-2MOA low virtually every new mag loaded, regardless of number of rounds loaded. Not sure why but this would skew results significantly so I pulled them out. My theory is that barrel cools down slightly between loadings, so wax hardens and slows bullet.

Please post results if you run this test yourself.

Setup:

- ER Shaw Barrel - ~600 Rounds prior to test.

- Action Block has "Foil Tape" bedding

- Harris bipod

- Trigger at lightest setting 1.5-1.75lbs

- Shot from prone with rear bag at 50yds

- Average of (3) 5-shot groups

- All shot with CCI Standard Velocity

Barrel was cleaned thoroughly prior to test and 50 rounds fired to settle in barrel before shooting groups and torque tuning. Results below, picture at bottom. Shot from right to left (10inlb to 50inlb).

Note that I pulled the first shot from most groups as it drops 1-2MOA low virtually every new mag loaded, regardless of number of rounds loaded. Not sure why but this would skew results significantly so I pulled them out. My theory is that barrel cools down slightly between loadings, so wax hardens and slows bullet.

- 10in/lb .38"

- 15in/lb .38"

- 20in/lb .45"

- 25in/lb .62"

- 30in/lb .35"

- 35in/lb .36" (factory setting)

- 40in/lb .53"

- 45in/lb .57"

- 50in/lb .37"

- 35 in lbs - first round low still present and second shot low left. Excluding first round, group measured .68" including last 14 shots but .48" for last 12 shots.

- 50inlbs - .49" 15 shot including all and .36" tossing first round (lowest round in left group). A second 15 shot group produced .49"/.72" group. Again tossed the first and, one called pull opened group full bullet diameter. Velocity was 1103 avg with SD of 12.

- 50inlbs with Federal Gold Medal Target: 3 15-shot groups with FGM Target produced .55" avg group. Not likely to get any better as they are traveling at 1120fps so a few rounds crack sound barriers and produced weird flyers. SD was 7.8.

Please post results if you run this test yourself.