Shooters,

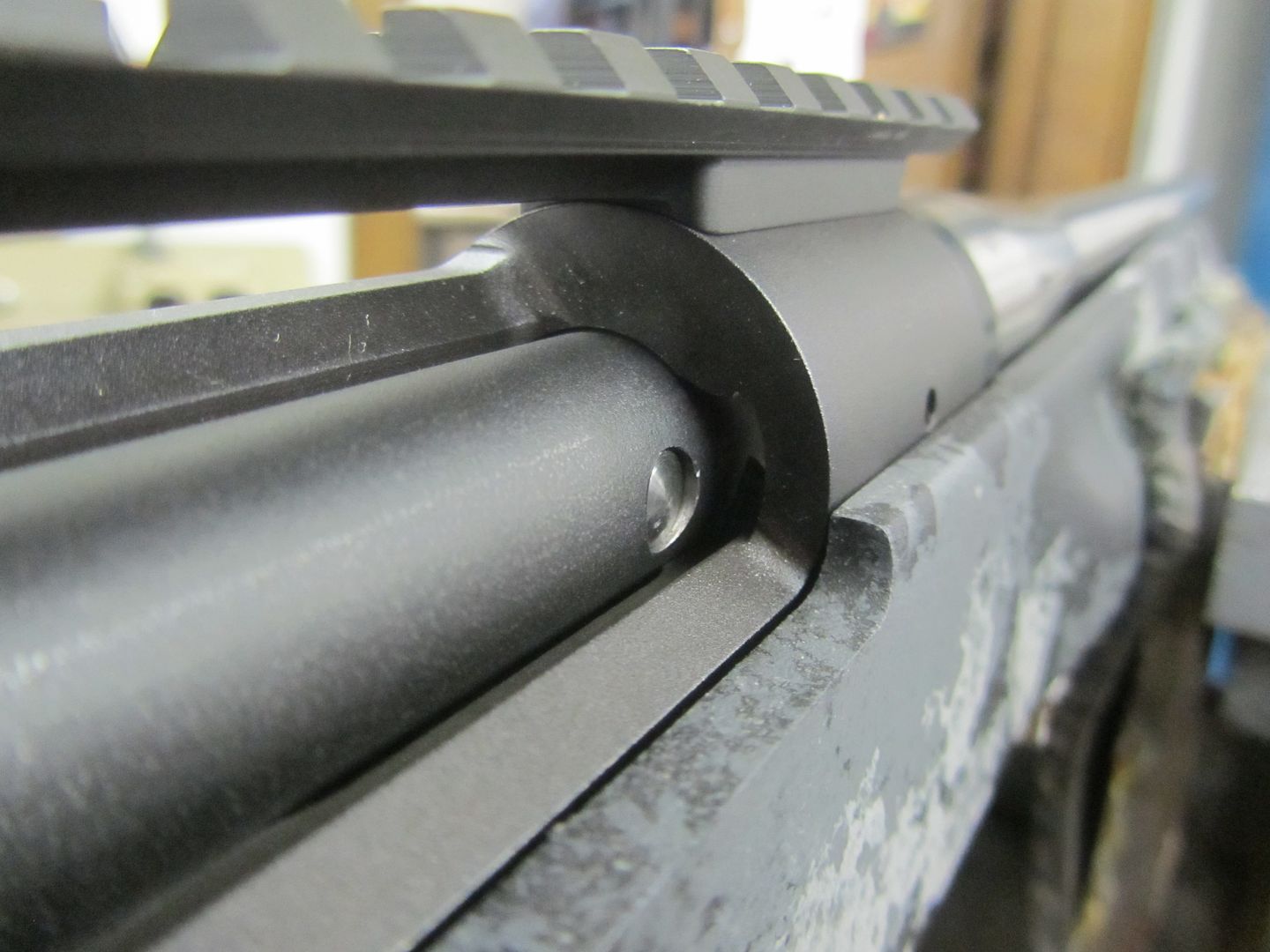

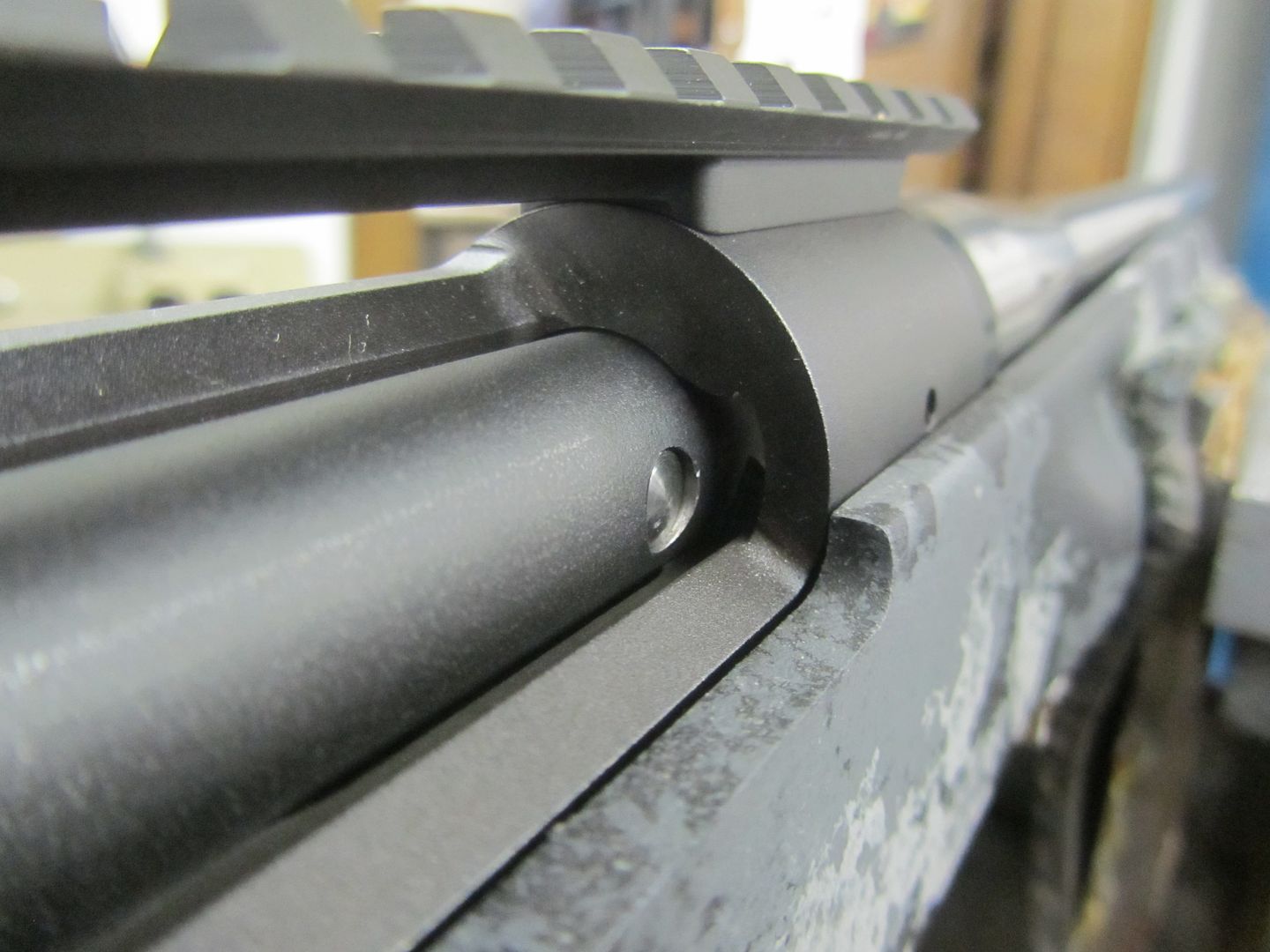

I posted this in another thread, but I thought I would share it here. I have been working on a floating bolt head Remington 700 conversion. It is not that difficult to do and has lots of benefits. I'm in the process of doing the accuracy testing and playing around with this rifle more and more. So far so good.

On paper, there should always be square lug contact, square bolt face and assuming the action is trued as mentioned above, it would yield near maximum accuracy potential with one negative effect that I can think of. Due to a sloppy bolt clearance, the firing pin will not be traveling perfectly parallel with the centerline of the action. This is something I can live with considering the benefits.

By adding the floating bolt head, I gain these benefits.

-I can install the bolt head in a fashion that brings the bolt handle as far as possible in the bolt handle cutout for maximum extraction.

-I can time the bolt handle timing perfectly

-Maintain Rem 700 reliability from the loose raceway while maintaining square bolt lug/face

-Guided, minimal clearance firing pin

-Post 64 style extractor.

-Gas Check behind the lugs

-Superior metallurgy on the lugs.

Mark

I posted this in another thread, but I thought I would share it here. I have been working on a floating bolt head Remington 700 conversion. It is not that difficult to do and has lots of benefits. I'm in the process of doing the accuracy testing and playing around with this rifle more and more. So far so good.

On paper, there should always be square lug contact, square bolt face and assuming the action is trued as mentioned above, it would yield near maximum accuracy potential with one negative effect that I can think of. Due to a sloppy bolt clearance, the firing pin will not be traveling perfectly parallel with the centerline of the action. This is something I can live with considering the benefits.

By adding the floating bolt head, I gain these benefits.

-I can install the bolt head in a fashion that brings the bolt handle as far as possible in the bolt handle cutout for maximum extraction.

-I can time the bolt handle timing perfectly

-Maintain Rem 700 reliability from the loose raceway while maintaining square bolt lug/face

-Guided, minimal clearance firing pin

-Post 64 style extractor.

-Gas Check behind the lugs

-Superior metallurgy on the lugs.

Mark