I started sizing a batch of 223 this morning. I noticed brass shavings and it seems the outside of the neck is being shaved down a bit. I can even feel with my fingernail just before the shoulder a slight edge. What am I doing wrong? This is a standard Lyman sizer.

- Thread starter gary55

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Got pics?

Are you lubing?

Are you lubing?

OAL length is under book maximum of 1.76Check your brass oal, check die set up, check inside of die for grit, debris, imperfections, etc if you haven’t already done these things. If you have, amend your post to reflect that.

Being a full length sizing die is there anymore setup to verify aside from depth in the press? I did back it off some with no improvement.

I cleaned the die before insertion in press.

Have you pulled the die apart to inspect it as I suggested initially?OAL length is under book maximum of 1.76

Being a full length sizing die is there anymore setup to verify aside from depth in the press? I did back it off some with no improvement.

I cleaned the die before insertion in press.

Eta: is this a new die? Or has this problem started recently, where prior to this, the die was working as it should/brass looked normal after sizing?

Last edited:

Exactly which die are you using?

Full length or neck only?

Case itself coming out sized correctly my measurements?

Full length or neck only?

Case itself coming out sized correctly my measurements?

I have disassembled the die and can't see anything not normal.

The die is not new, I got it used from a friend that stated this never happened to him. I personally have not seen it operate correctly.

I'm not sure the neck thickness could be more than is given between the expander and die body, especially with multiple headstamps and every case has a slight amount of material removed.

Using full length, cases are coming out correctly sized. All is good except the neck is losing just a bit of brass.

The die is not new, I got it used from a friend that stated this never happened to him. I personally have not seen it operate correctly.

I'm not sure the neck thickness could be more than is given between the expander and die body, especially with multiple headstamps and every case has a slight amount of material removed.

Using full length, cases are coming out correctly sized. All is good except the neck is losing just a bit of brass.

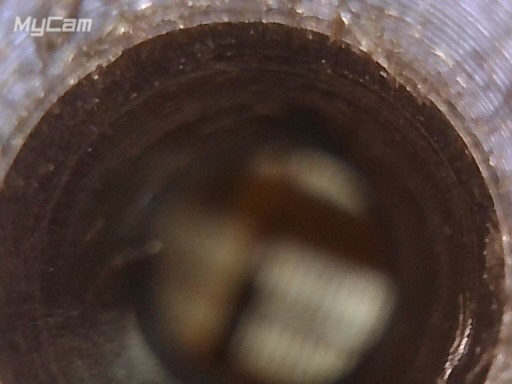

Took some photos with my bore scope. Almost looks like there's part of a neck busted off inside the die. When I run the camera in from the threaded end, where the decapping rod goes in, I don't see an edge though. This, if that's what's going on, had to have been there when I bought it. All my cases have their necks still attached. I measured the ID of a few sized necks and I'm getting .215, what is a 223Rem sized down to normally?

My size down to .246 and expand to .247 and my seated is .249 outside dimensions.Took some photos with my bore scope. Almost looks like there's part of a neck busted off inside the die. When I run the camera in from the threaded end, where the decapping rod goes in, I don't see an edge though. This, if that's what's going on, had to have been there when I bought it. All my cases have their necks still attached. I measured the ID of a few sized necks and I'm getting .215, what is a 223Rem sized down to normally?

View attachment 7816396View attachment 7816397View attachment 7816398

.249-.224=.025 of neck material

.246-.025=.221 inside sized dimension.

You found your issue with that beaver dam of shit.

Now to get it out…

Have a bronze brush? Try running that in and out and then halfway in and try to reverse letting the bristles act as barbs to pull the crap out. Hopefully.

Maybe some sand paper on a dowel for grit to rub it out and then lapping compound to smooth out any scratches.

Or just buy a new die for the 30 bucks or whatever it costs and not deal with the shit.

You could also try a dental pic to see if that can be peeled off without scratching too much. You then can use some 600-800 grit sandpaper to polish the neck area without removing too much metal. I had to do this with a 223 die that had some brass galled in the neck and was scratching the neck. It worked perfectly.

My issue was caused by resizing dirty brass. All of my brass that touches the ground get put into a tumbler for 30 minutes to get any sand / dirt grit off of the brass before sizing.

My issue was caused by resizing dirty brass. All of my brass that touches the ground get put into a tumbler for 30 minutes to get any sand / dirt grit off of the brass before sizing.

Or just buy a new die for the 30 bucks or whatever it costs and not deal with the shit.

This is the perfect excuse to go for that new fancy sizing die you've been eyeing but couldn't justify.

Look at the photos in post #10. You'll see why the necks look peened over.Your case neck looks peened over. your die might be shaving it off

I should think semi- chrome on a bore mob chucked into a drill would do the trick…after he gets the bulk copper out of the die. Right?I sent a die back to the manufacturer because it was goulding causing deep scatches in the neck. They ultra sonic cleaned and polished it. Even if you get cleaned up it will gould up again if you don't polish it.

Similar threads

- Replies

- 5

- Views

- 346

- Replies

- 134

- Views

- 4K