Okay... the self appointed mall cops of reloading might want to go watch a rerun of Gomer Pyle about now...

For the rest of us, here's a short video we made today...

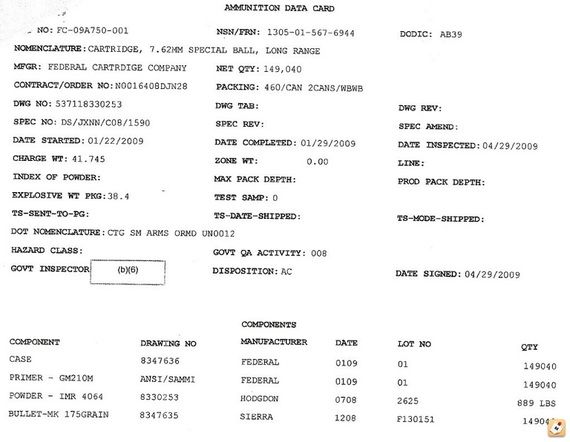

Sleuthing the Federal Gold Medal Match long range load recipe. - YouTube

Dan

For the rest of us, here's a short video we made today...

Sleuthing the Federal Gold Medal Match long range load recipe. - YouTube

Dan