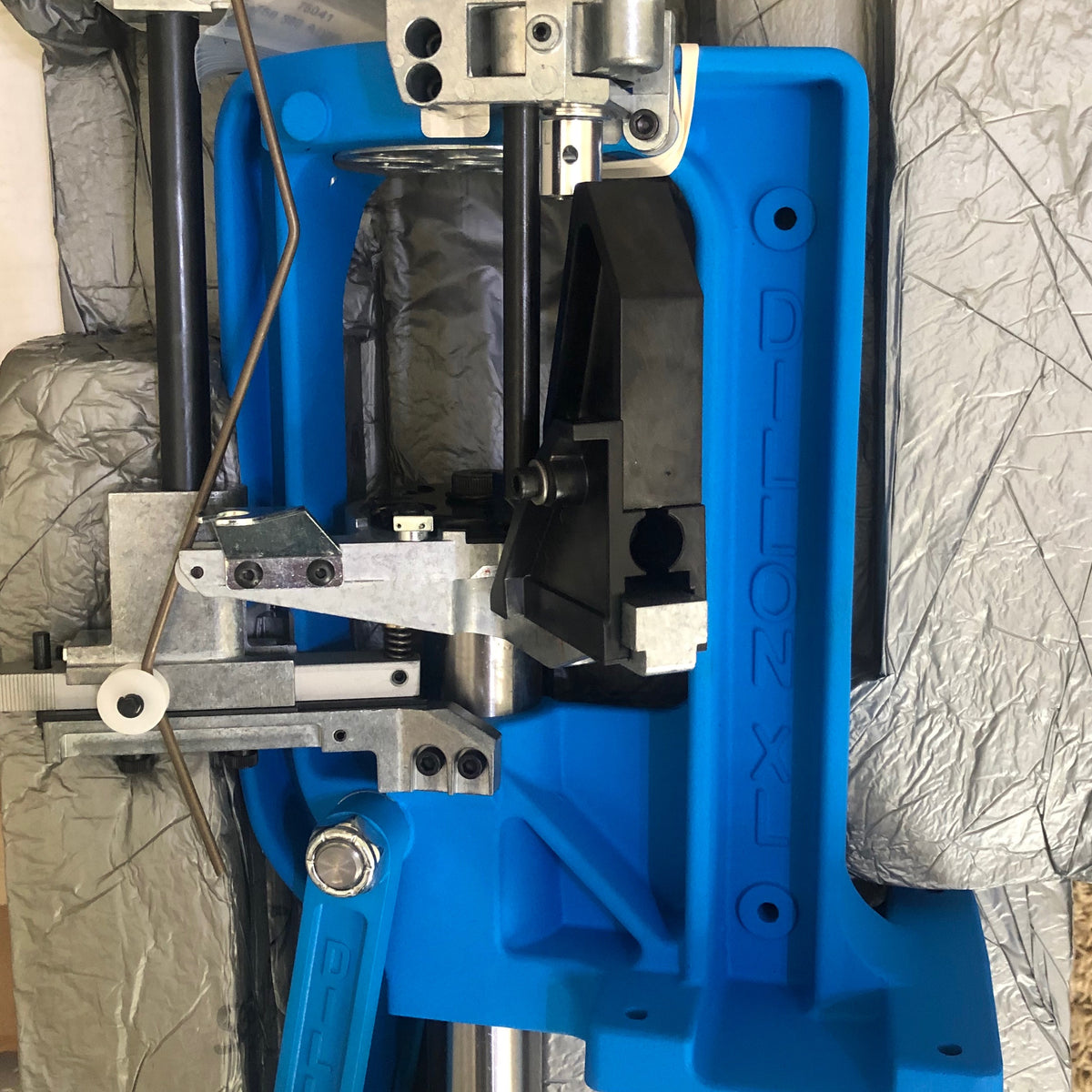

I’ve come across a 750 for sale. Has the 9x19 and the 6.5 man bun conversion kits and a set of Hornady 6.5 dies.

Also comes with 1700 primers and all the OEM accessories.

There’s a roller handle installed too, but other than that, it’s a factory setup.

The guy selling has pumped out about 300 round with it and doesn’t use it anymore.

Other than an Inline Fabrication mount, is there any other things that helped make it easier to use the press? Meaning make it more ergonomically friendly?

I don’t want to dump a ton of money into it as I don’t shoot enough to justify the extra costs quite yet.

Initially, I’ll only load pistol rounds on it. Start with 9 and then maybe buy another setup for 40.

Is there anything you learned that was an “oh shit” moment?

Also comes with 1700 primers and all the OEM accessories.

There’s a roller handle installed too, but other than that, it’s a factory setup.

The guy selling has pumped out about 300 round with it and doesn’t use it anymore.

Other than an Inline Fabrication mount, is there any other things that helped make it easier to use the press? Meaning make it more ergonomically friendly?

I don’t want to dump a ton of money into it as I don’t shoot enough to justify the extra costs quite yet.

Initially, I’ll only load pistol rounds on it. Start with 9 and then maybe buy another setup for 40.

Is there anything you learned that was an “oh shit” moment?