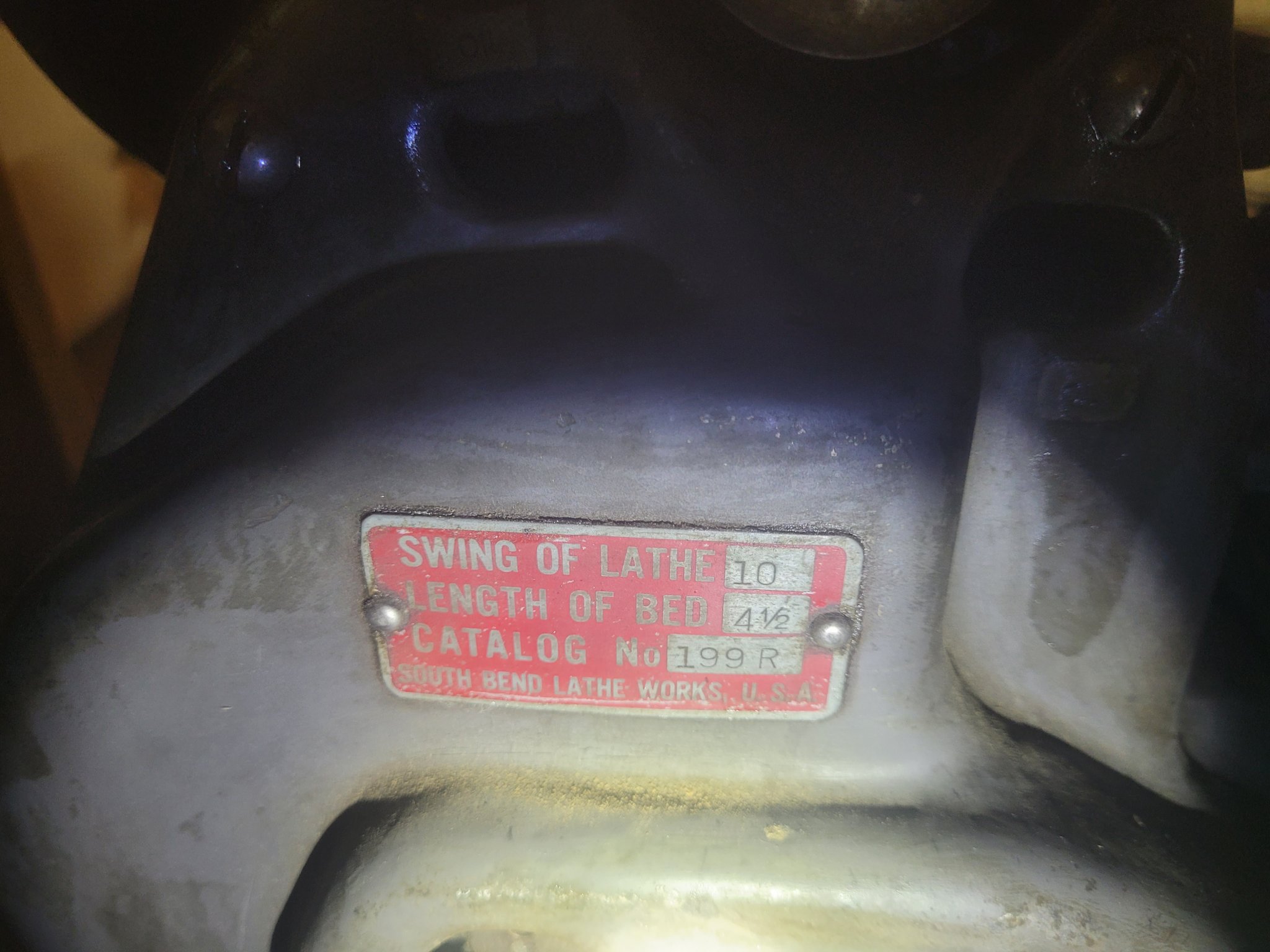

I picked this guy up today for 100 bucks plus some work.

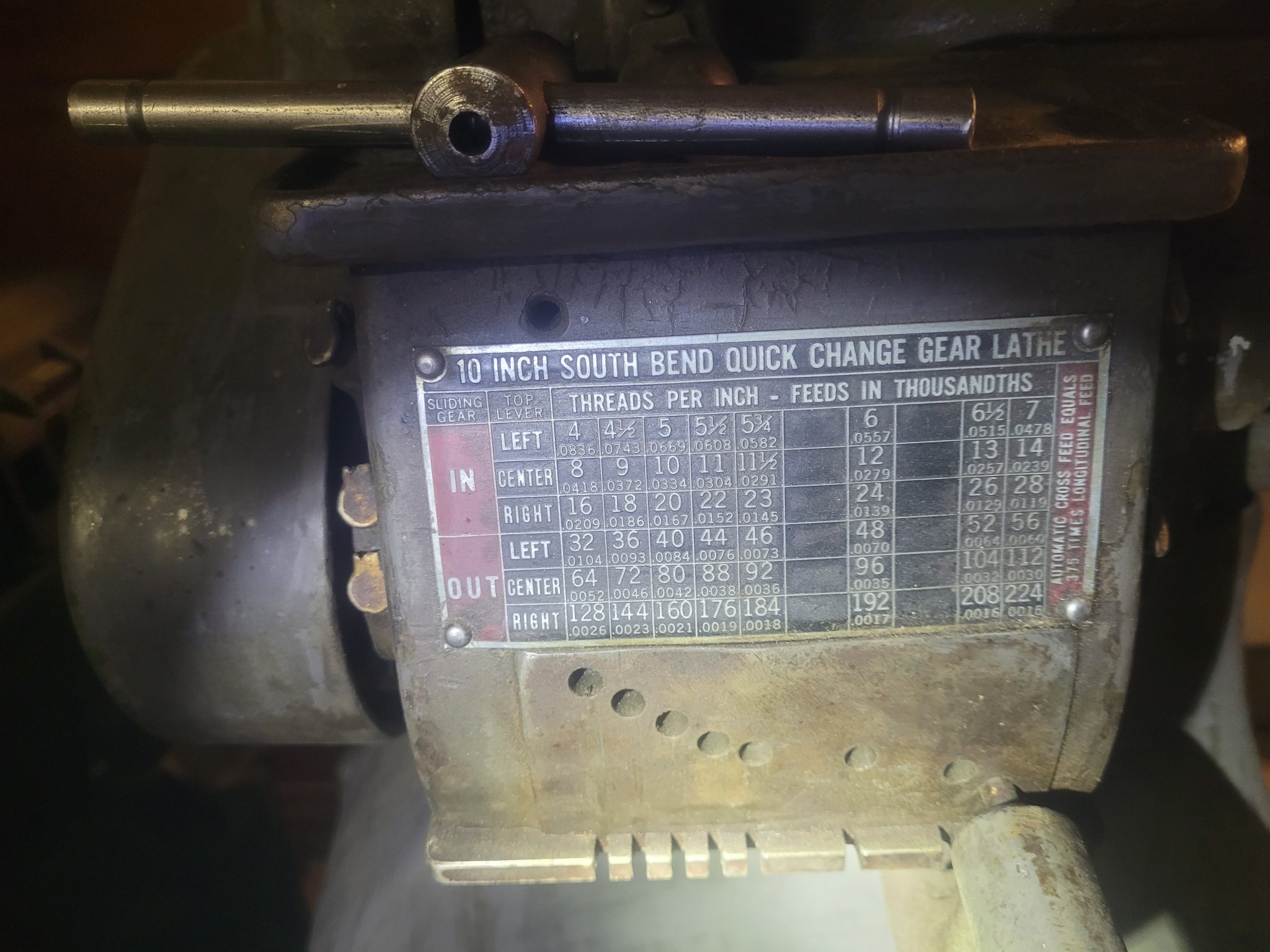

Anyone know where I can get a manual for this guy? The ways have no wear and scrape marks along the whole length of the ways.

Serial is just above 170,000.

@sirhrmechanic

Anyone know where I can get a manual for this guy? The ways have no wear and scrape marks along the whole length of the ways.

Serial is just above 170,000.

@sirhrmechanic