I have a Springfield M1A but want something better, possibly in 6.5 CM. Is it possible to build a sub MOA AR10 for around $1000 without optics? If so, what would you recommend in it?

- Thread starter AKMsoldier

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Probably not realistic. $2k is doable and 2500 will get you good quality components. There are a few complete factory built options in that price that might do it like the Springfield saint 308 but I’ve not personally run one.

At that price point if accuracy is a major concern I think you’d be better off running a bolt on a tikka than cutting corners on a gas gun.

At that price point if accuracy is a major concern I think you’d be better off running a bolt on a tikka than cutting corners on a gas gun.

Might be tough, especially now. I built mine in the spring, collected parts for about 6 months. Got in on some Black Friday deals and bought some used parts. Used upper, handguard, JP spring, trigger, blemished lower, new barrel and a few minor parts. I had about $1200 in mine, but it is a sub-MOA 6.5 CM

I actually meant "normal times" prices. Right now everything is inflated. The TIKKA T3X TAC A1 I would consider is at least $1800 now and normally you can get it for $1500 or so. I can wait for a year or so. What made me think of $1000, possibly $1200 are some inexpensive uppers like PSA that include BCG and charging handle in the price. I assume even a 20" barrel should give me a good chance to test 800 yards. I already spent $750 or so on a new TRACT TORIC scope.

20" should easily get you 800 yds in a 6.5. I've had mine out to 1K, no problem, 20" Wilson Combat barrel.

Your Wilson Combat also has a reputation of a high accuracy barrel. Does it make sense to actually buy a very good 24" barrell like Wilson Combat, other upper parts and have the upper assembled to save money or rather pay similar money for better accuracy?

I had a specific size in mind when I built mine, and I assembled it myself. Buying a matched barrel and bolt might help, as well as having it put together.

What would be the best 6.5 CM 20-25" barrel for 1000 yards for less than $400?

The S&W M&P-10’s have been known to be sub MOA, and they offer 6.5CM. I think they come in around or under $1K. Personally I think full size cartridges in a semi-auto have way too many draw backs, particularly for long range.

ar10 can be finicky builds by them selves, but anything it is possible if you wait for big sale days. Buy a matched barrel / bolt from a reputable shop and a matched upper / lower of the same quality and the rest can be budget friendly.

Buy a psa10 and swap the barrel and there you go. Won’t look like a Gucci rifle or anything but it’ll work

Tikka t3x tac 1a does look like Gucci IMHO and for 1000 yards it probably will shoot better than nor so expensive ar10. If I have the new rifle mainly for 500 yards, Getting a psa10 and swapping the barrel may be the best optin.

Glad for you. I was looking at the same DPMS model for a while until DPMS stopped making and selling ARs. PSA may be not a bad gamble. If ot doesnt work well for 1 MIA, I will just have to replace the barrel. I now more worried abour reliability of AR vs bolt. If you have just 1 chance to make thet 1 shot at a long range, is AR reliable enough to use it

I got a stock bushmaster for $600 a few months ago, free-floated the barrel and installed an adj gas block. Shoots sub moa with 175gr fgmm and handloads. I spent about $400 on trigger, handguard, stock, and pistol grip. So yeah, $1k gas gun is doable.

ARs are as reliable as you make them. Honestly, I’ve seen way more issues with bolt rifles in prs comps than I have with ARs. Mags are the major failing point of any firearm, and the plethora of stocks and actions seems to make the mags problematic. Not to mention that the industry seems to have standardized on the AICS, which I think is a crap mag. The AR mag, however, is pretty damned good. It is not uncommon to see multiple people in one squad have issues with their bolt gun. I’ve had a mag issue in one comp with my AR. Replaced the mag and no more problems. Elander’s suck with the 6.5 Grendel. Here’s a not uncommon issue I’ve seen with bolt guns and aics mags...

the industry seems to have standardized on the AICS, which I think is a crap mag.

Truth

Whoops posted in the wrong thread (the general AR10 thread) but will repost here as well.

Here's my build. It came in at $1015 with 2 pmags and it was a few years ago. Also note that I spent a bit more because I did 80% and you could probably shave a few bucks there and minus irons and optics I have on the gun too. It's an absolute zero frills budget build when it comes to furniture however I put the money where I thought it counted (e.g. barrel, trigger.)

The Sportical upper was kind of a mistake since I wanted to have iron sights as well but if you had a piece of glass with a large objective I could appreciate why you'd want it.

Worth noting is that you have to do your homework if you build an LR308 or AR10 style gun. The parts aren't as universal as an AR15 even within the lines. There's something like 3 heights of LR308 uppers for instance.

If I was looking for a pre built gun I'd be looking at the M&P 10 or the PA10 6.5 Creed. With reloading I'd think either could break into the sub MOA range. If you haven't yet look at Elfster's series on the PA10 6.5 CM.

Here's my build. It came in at $1015 with 2 pmags and it was a few years ago. Also note that I spent a bit more because I did 80% and you could probably shave a few bucks there and minus irons and optics I have on the gun too. It's an absolute zero frills budget build when it comes to furniture however I put the money where I thought it counted (e.g. barrel, trigger.)

The Sportical upper was kind of a mistake since I wanted to have iron sights as well but if you had a piece of glass with a large objective I could appreciate why you'd want it.

Worth noting is that you have to do your homework if you build an LR308 or AR10 style gun. The parts aren't as universal as an AR15 even within the lines. There's something like 3 heights of LR308 uppers for instance.

If I was looking for a pre built gun I'd be looking at the M&P 10 or the PA10 6.5 Creed. With reloading I'd think either could break into the sub MOA range. If you haven't yet look at Elfster's series on the PA10 6.5 CM.

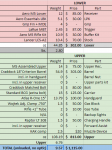

| upper/lower/jig | $279.00 | Upper “sportical” |

| Rail | $50.00 | Ebay Tube |

| Barrel | $250.00 | Mcgowen Black Friday |

| Trigger | $100.00 | POF 3.5# Black Friday |

| Gas Tube | $15.00 | Rifle length |

| Gas Block | $23.00 | DPMS LR308 |

| Stock, Buffer, Spring | $70.00 | |

| Sighting | ||

| Charging Handle | $60.00 | (wanting to say this came out cheaper, stock style with "tactical latch." |

| Bolt | $123.00 | Daytona Tactical |

| Flash Hider/brake(?) | ||

| Mags | $45.00 | Pair of PMAG 25rd |

| 1015 before flash hider and glass |

I got a 16" DPMS barrel and bolt Carrier from here. I was going to get a faxon 16" with the head spaced bolt but they have been out of stock sense forever. I took apart a palmetto state armory 6.5 CM upper and sold the barrel and BCG. I lapped the receiver face and assemble it all on my lower with the Rock River two stage for less than a grand. It is on average firing .9 MOA sometimes a little better, sometimes a little worse. It can be done with some accurizing and patience.

Not gonna happen. A worthy barrel and trigger is going to eat up over half of that budget. I don’t think there’s even a “reliable” AR10 for a grand, let alone a sub MOA one.

Best bang for the buck for a large frame precision gasser is a Seekins SP10 bought with a 30% off coupon (you can get them on here for like $25) or a LMT MWS.

Best bang for the buck for a large frame precision gasser is a Seekins SP10 bought with a 30% off coupon (you can get them on here for like $25) or a LMT MWS.

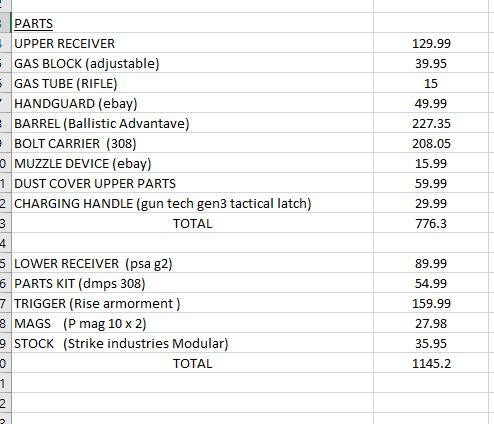

I built one in 2018 PSA Gen2 Upper and lower, Rise Armament trigger, Ballistic advantage barrel, Not even sure of the name brand Bolt carrier and all associated parts and pieces were under 1200

Some parts took some fitting since i wasnt loyal to one brand because i was shopping best deals.

Found the barrel, adjustable gas block on clearance. Waited for sales on other parts

Shots 1/2 moa 3 shot groups (doesnt tell too much but im impressed with its precision)

Some parts took some fitting since i wasnt loyal to one brand because i was shopping best deals.

Found the barrel, adjustable gas block on clearance. Waited for sales on other parts

Shots 1/2 moa 3 shot groups (doesnt tell too much but im impressed with its precision)

Last edited:

Impressive.... Ballistic advantage means .308barrel. I dont think they make 6.5 CM.

Impressive.... Ballistic advantage means .308barrel. I dont think they make 6.5 CM.

They make 6.5

This was 227.35 shipped on clearance

Here is a picture of one of the groups @ 100 yards with Hornaday Black.

Impressive.... Ballistic advantage means .308barrel. I dont think they make 6.5 CM.

22" on sale now for $250

Wow! That's a good accuracy and a good deal! Is it easy to replace the barrel by myself?

Wow! That's a good accuracy and a good deal! Is it easy to replace the barrel by myself?

yes, just go to hobby lobby and get a wooden dowel that matches the BCG diameter and hit it out the front. having the receiver in a vice is a good idea also

I think I will just a pay gunsmith to do it. If buy a 20" PSA upper, can I put a 22 or 24" barrel on ot? Also, do I need fluted or non fluted?

I think I will just a pay gunsmith to do it. If buy a 20" PSA upper, can I put a 22 or 24" barrel on ot? Also, do I need fluted or non fluted?

not trying to talk you into doing something you're uncomfortable with but.... I built an AR10 because its modular to an extent and changing out parts doesnt require a gunsmith. At the end of the day i know that everything good or bad with my gun was done by me. Its hard to buy that type of quality control.

Barrel Length- thats a personal choice Longer is higher velocity but more weight and less maneuverability

Fluted - less weight and more cost.

These all depend on what you want to do with the gun.

I think I will just a pay gunsmith to do it. If buy a 20" PSA upper, can I put a 22 or 24" barrel on ot? Also, do I need fluted or non fluted?

So you want to piece together a sub $1000 rifle but your paying a gunsmith to build it?

Thats not how it works. If your going to do that, simply buy a complete rifle or at least upper.

not trying to talk you into doing something you're uncomfortable with but.... I built an AR10 because its modular to an extent and changing out parts doesnt require a gunsmith. At the end of the day i know that everything good or bad with my gun was done by me. Its hard to buy that type of quality control.

Barrel Length- thats a personal choice Longer is higher velocity but more weight and less maneuverability

Fluted - less weight and more cost.

These all depend on what you want to do with the gun.

If you have an automotive torque wrench they're not bad provided you don't have a pinned gas block. If that's the case they can be a pain. This is pretty much it and I'm sure there's a YT video somewhere:

-Pop the FH off if your gas block hole is smaller than it is. You need this off because the gas tube goes through the nut.

-Pull the raill off. This will expose the barrel nut. There's a lot of depends here, not sure on how the PSA one is set up.

-Get the barrel nut off. This is probably the one real proprietary tool you'll need perhaps something to hold it in a vise.

-After this the barrel should just slide out with some wiggling. You may need a dowel as mentioned but not a biggie.

Install is a hint more complicated. The range they give for torquing a barrel nut is REAL diverse (double check but it's something around 30-70 ft-lbs) and that's good because you need to get one of the gas tube holes to line up when you're torquing it in. If you have to loosen it up and re-torque and that will give you the last bit you need some times. After that put the gas block, hand guard, and muzzle device on and you're squared away. A go/no go gauging here is probably a good idea but many many people get away without doing it on an AR build. That I leave up to you decision wise.

The only real proprietary tool you've got there is the barrel nut wrench. There are a myriad of them be careful to get the right one. Ask around your local gun club someone may be able to help you out/lend you a torque wrench and barrel nut wrench as needed.

Also, you may or may not be able to re-use the gas tube and block depending on the barrel you order. Keep it in mind not huge expenses but an extra $75ish if you need to get both. May as well spend a few bucks and do adjustable gas and possibly a +2 or +3 tube at the same time. I'm not sure what the PA10 in 6.5 comes with but I'd want rifle length minimally and would possibly prefer +2 or +3 inch gas depending on if I were reloading for it or not.

In terms of having a smith do it, I would probably hesitate unless you can't access the tools cheap/free. It should only really be a shop hour IMO so the cost may end up being a wash if you have to pay for tools. That said this is a beer budget gun you don't always get luxuries like having someone smith your stuff for you (as said above.)

If you have an automotive torque wrench they're not bad provided you don't have a pinned gas block. If that's the case they can be a pain. This is pretty much it and I'm sure there's a YT video somewhere:

-Pop the FH off if your gas block hole is smaller than it is. You need this off because the gas tube goes through the nut.

-Pull the raill off. This will expose the barrel nut. There's a lot of depends here, not sure on how the PSA one is set up.

-Get the barrel nut off. This is probably the one real proprietary tool you'll need perhaps something to hold it in a vise.

-After this the barrel should just slide out with some wiggling. You may need a dowel as mentioned but not a biggie.

Install is a hint more complicated. The range they give for torquing a barrel nut is REAL diverse (double check but it's something around 30-70 ft-lbs) and that's good because you need to get one of the gas tube holes to line up when you're torquing it in. If you have to loosen it up and re-torque and that will give you the last bit you need some times. After that put the gas block, hand guard, and muzzle device on and you're squared away. A go/no go gauging here is probably a good idea but many many people get away without doing it on an AR build. That I leave up to you decision wise.

The only real proprietary tool you've got there is the barrel nut wrench. There are a myriad of them be careful to get the right one. Ask around your local gun club someone may be able to help you out/lend you a torque wrench and barrel nut wrench as needed.

Also, you may or may not be able to re-use the gas tube and block depending on the barrel you order. Keep it in mind not huge expenses but an extra $75ish if you need to get both. May as well spend a few bucks and do adjustable gas and possibly a +2 or +3 tube at the same time. I'm not sure what the PA10 in 6.5 comes with but I'd want rifle length minimally and would possibly prefer +2 or +3 inch gas depending on if I were reloading for it or not.

In terms of having a smith do it, I would probably hesitate unless you can't access the tools cheap/free. It should only really be a shop hour IMO so the cost may end up being a wash if you have to pay for tools. That said this is a beer budget gun you don't always get luxuries like having someone smith your stuff for you (as said above.)

I dont see alot of Pinned gas blocks on AR10's

You might have been able to get a sub $1,000 MOA capable rifle before the pandemic, but even then you'd need to be patient and shop sales. These days you will have a hard time finding sales with most parts selling out at MSRP. I think you'd need to spend a minimum of $1500 today, and that's if you're patient and get lucky on Black Friday. If you want to get something quickly, you might be creeping up to the $2000+ range.

I started picking up parts around late 2018 for my build, with the most expensive part being a Craddock Precision Criterion barrel that was on clearance for $300 (excellent deal!). I waited for sales on literally everything else. I picked up a blemished lower, got an upper builders kit & charging handle from the Schuyler Arms Black Friday sale, and had some other parts (gas block, buffer/tube, triggers) left over from old builds. The rest were picked up used or on clearance. I attached my build list & pricing - mine came out to $1115 before taxes, fees, optics or magazines. I didn't skimp out on quality, but didn't pay extra for premium parts either.

Whatever you do, start with a quality barrel & matched bolt for the highest likelihood of getting a precise shooter. Most of the rest comes down to personal preference. If you can, be sure to true the receiver and bed the barrel for more consistency.

I started picking up parts around late 2018 for my build, with the most expensive part being a Craddock Precision Criterion barrel that was on clearance for $300 (excellent deal!). I waited for sales on literally everything else. I picked up a blemished lower, got an upper builders kit & charging handle from the Schuyler Arms Black Friday sale, and had some other parts (gas block, buffer/tube, triggers) left over from old builds. The rest were picked up used or on clearance. I attached my build list & pricing - mine came out to $1115 before taxes, fees, optics or magazines. I didn't skimp out on quality, but didn't pay extra for premium parts either.

Whatever you do, start with a quality barrel & matched bolt for the highest likelihood of getting a precise shooter. Most of the rest comes down to personal preference. If you can, be sure to true the receiver and bed the barrel for more consistency.

Attachments

I dont see alot of Pinned gas blocks on AR10's

True but mentioned it because old man murphy likes that sort of shit.

If you only plan on doing one it doesn't make much sense to buy the tools needed to do it right. If you're going to be building a few then yeah you might as well get all the tools to do-it-yourself. If you're taking it to a smith make sure that they lap the upper receiver before setting the barrel.

If you're taking it to a smith make sure that they lap the upper receiver before setting the barrel.

Fuck that. Buy a quality upper with good machining tolerances instead. Do you really think a $40 lapping tool slapping around in the raceway like a dick in a loose hooker pussy and attached to a dewalt is going to get the receiver face straighter than a CNC? Nahhhhh. That’s how you ruin a good receiver.

If you only plan on doing one it doesn't make much sense to buy the tools needed to do it right. If you're going to be building a few then yeah you might as well get all the tools to do-it-yourself. If you're taking it to a smith make sure that they lap the upper receiver before setting the barrel.

lapped vs not lapped. what real world results do you get from this.

Maybe dont buy your tools from china.Fuck that. Buy a quality upper with good machining tolerances instead. Do you really think a $40 lapping tool slapping around in the raceway like a dick in a loose hooker pussy and attached to a dewalt is going to get the receiver face straighter than a CNC? Nahhhhh. That’s how you ruin a good receiver.

If you have cheap off the rack parts not much but if you're spending the money on a barrel and other quality parts it helps to stack the tolerances. I haven't done any before and after comparing with the intent to see, but I think I should.lapped vs not lapped. what real world results do you get from this.

Thanks for all advice! I definitely will do most of the shopping after the pandemic is gone. I do have some tools in the garage but when I was building my AR15 the local gun shop sales guy did assemble the lower and everything except for the upper for just $30. I guess its just fun for him - not the way to make money. Since the objective is to do consistent reliable and reasonably accurate shooting to up to 1000 yards, I may have to stick with 24" barrel. Weight does not matter here. For short range action I would still only trust my Soviet made SKS.

Maybe dont buy your tools from china.

If you have cheap off the rack parts not much but if you're spending the money on a barrel and other quality parts it helps to stack the tolerances. I haven't done any before and after comparing with the intent to see, but I think I should.

Curious if you do, post results. Also do forged vs billet uppers too. It amuses me that people will be all "a billet upper is stiffer" and yet I have as of yet to ever see word one about a quantifiable gain it offers.

Last edited:

1. end of barrel centered in handguard.lapped vs not lapped. what real world results do you get from this.

2. rear iron sight not maxed out on windage when zero'ing.

3. good flat contact for barrel extension flange on receiver face.

it doesn't make the gun "more accurate", just provides a more solid, stable mounting of barrel to receiver.

1. end of barrel centered in handguard.

2. rear iron sight not maxed out on windage when zero'ing.

3. good flat contact for barrel extension flange on receiver face.

it doesn't make the gun "more accurate", just provides a more solid, stable mounting of barrel to receiver.

Now that you mentioned that I've done 3 fixed sight builds since I started lapping and they are all at mechanical 0 on windage compared to others needing a click or few one way or the other.

1. end of barrel centered in handguard.

2. rear iron sight not maxed out on windage when zero'ing.

3. good flat contact for barrel extension flange on receiver face.

it doesn't make the gun "more accurate", just provides a more solid, stable mounting of barrel to receiver.

looks like im in the market for a new tool lol

You aren't near as smart as you think you are. A smith that knows what he is doing can take a 1980s piece of shit cast receiver and make it shoot 1/2 MOA but you don't know how do you?Fuck that. Buy a quality upper with good machining tolerances instead. Do you really think a $40 lapping tool slapping around in the raceway like a dick in a loose hooker pussy and attached to a dewalt is going to get the receiver face straighter than a CNC? Nahhhhh. That’s how you ruin a good receiver.

The DPMS G2 has a pretty good 2 stage in it, swap the barrel to a Creed or 260 with the proper size gas port or an adjustable gas block and do a few tricks and it will work. The old style DPMS LR can be built to do it also but they will need a better trigger, The RRA 2 stage is about as cheap as you can get away with. Lots of people bad mouth the DPMS but it's a base that can be built on and they really don't take that much to get Sub MOA, not near as much as a M1A does. I have 1 of each DPMS, both weigh around 7lbs with 16 and 18" barrels and both are easily sub-MOA.I have a Springfield M1A but want something better, possibly in 6.5 CM. Is it possible to build a sub MOA AR10 for around $1000 without optics? If so, what would you recommend in it?

The double lug M1As I had back in the 90s took a crap load of work and still weren't as accurate. Most HP shooters will say 1 MOA is fine for HP because the shooters position and technique will affect score more than the accuracy of the firearm.

Last edited:

First off it makes sure the lugs of the barrel extension are square with the receiver bore and the bolt lugs bear the thrust evenly. Same as squaring the receiver threads and lapping lugs on a bolt gun.lapped vs not lapped. what real world results do you get from this.

If the barrel extension fits tight in the receiver you don't need to square the receiver since the ID of the receiver and OD of the extension hold everything .

The other thing is you want a strong rigid connection at the barrel and receiver since that is part of the scope to barrel connection. Since the 80s we have been bedding the extension in the receiver to make that connection as strong as possible.

Right about 1k. Very much SUB moa with some load development

www.youtube.com

www.youtube.com

PSA 6.5 CREEDMOOR GEN3 AR10 SERIES!

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

Similar threads

- Replies

- 35

- Views

- 937