My buddy texted me this pic of his yankee hill ti suppressor. First shot of the day it blew out the side. He said it was factory 308 ammo, I believe Black hills 175. There was not barrel obstruction. Any ideas on what caused this? What are the chances of this getting warrantied? I will try to get some more details.

Suppressors Suppressor blew up

- Thread starter Mooseknuckles

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Definitely looks like some sort of manufacturing defect. How old is the supressor?

Let us know what they say. This is interesting and hopefully the cover it. The problem is I don’t see that being repaired and he’s gonna have to wait for a new tax stamp with a new serial number.

YHM Support

Couldn't they just enscribe the same serial in the new supressor and destroy the defective one?

Couldn't they just enscribe the same serial in the new supressor and destroy the defective one?

NO! Not allowed.

- Nov 3, 2010

- 8,645

- 17,545

If I’m not mistaken YHM used to not warranty suppressors one barrel lengths less than 10.5 inches. That was the case when building my 300BO SBR when I called and asked but that was 10 years ago

Attachments

Was it cleaned prior to this first shot?

It does look like where the Y intersected the diamond may have been a week point.

It does look like where the Y intersected the diamond may have been a week point.

This is what he is worried about.Let us know what they say. This is interesting and hopefully the cover it. The problem is I don’t see that being repaired and he’s gonna have to wait for a new tax stamp with a new serial number.

If it was a baffle strike then I wouldn’t see it being an issue.

Last edited:

My buddy texted me this pic of his yankee hill ti suppressor. First shot of the day it blew out the side. He said it was factory 308 ammo, I believe Black hills 175. There was not barrel obstruction. Any ideas on what caused this? What are the chances of this getting warrantied? I will try to get some more details.

I saw Ti Gemtech blow out like that once. Definitely a problem in the can.

Titanium likes to crack at the engraving. Nothing new.

My buddy texted me this pic of his yankee hill ti suppressor. First shot of the day it blew out the side. He said it was factory 308 ammo, I believe Black hills 175. There was not barrel obstruction. Any ideas on what caused this? What are the chances of this getting warrantied? I will try to get some more details.

View attachment 7305045View attachment 7305046

Moose,

Did your friend call YHM? I am very interested in finding out what they say.

Launched a YHM down range a few years back on an M16. No baffle strike but it got shot in the air if I remember right. Only weld holding it together was the fusion pass on the end of the core to the tube. It failed and launched the guts down range.

Launched a YHM down range a few years back on an M16. No baffle strike but it got shot in the air if I remember right. Only weld holding it together was the fusion pass on the end of the core to the tube. It failed and launched the guts down range.

View attachment 7305463

Was it on Auto or just Semi when it happened? Either way, that is crazy......

Back then we didn’t use the semi auto function much on the MGs. (-:

Semi what?????....LOL

Is the serial in the mid of the can? I wonder how they'll repair it.

They cut it off before the sn and reweld the sleeve that point

Any metal is weaker where its thickness is reduced, as by engraving. They allow for that by keeping the engraving shallow and the wall-thickness up.

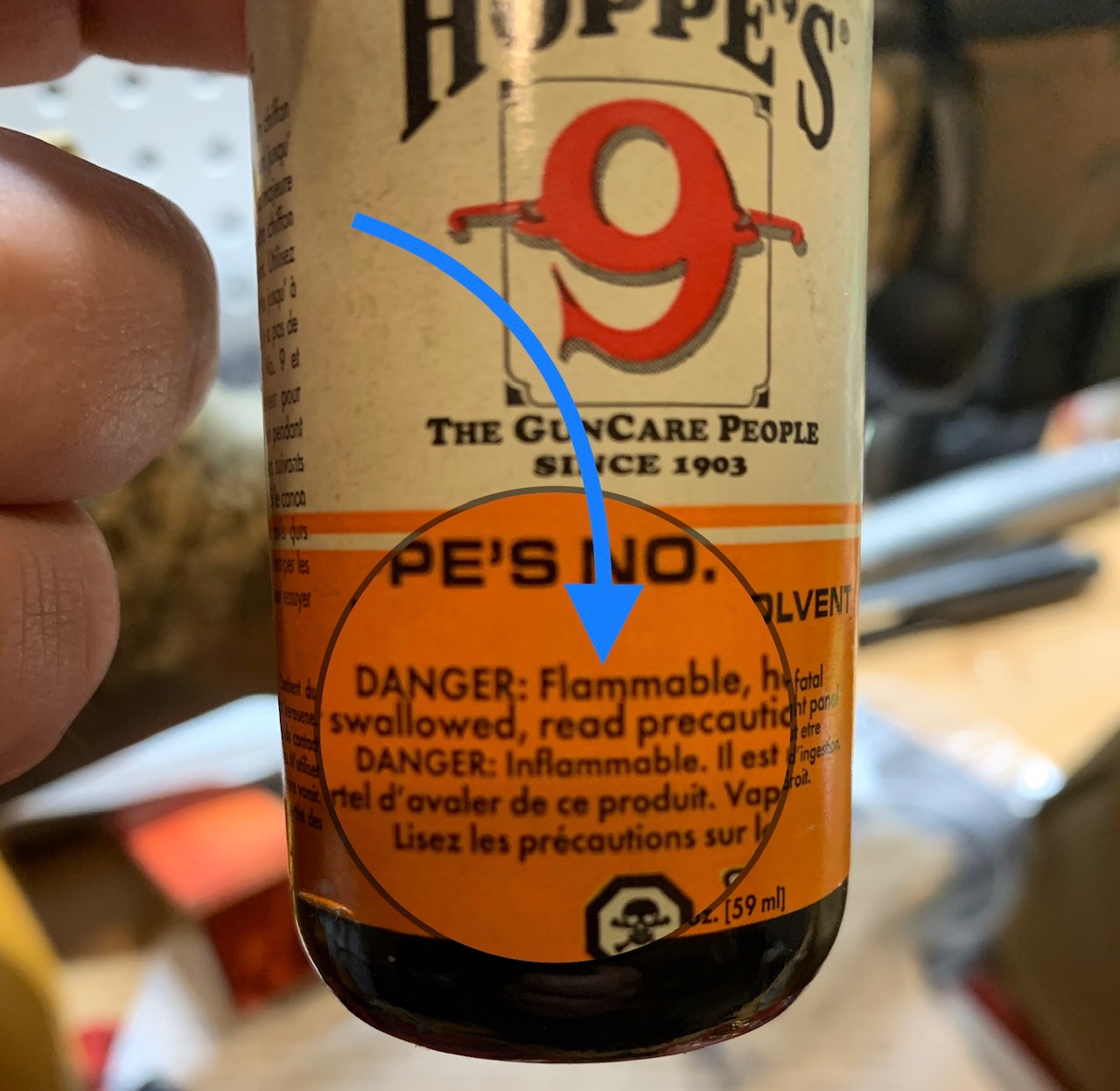

A 5 year old YMH is not going to be shy of wall-thickness. They are nothing if not stout. I also think it would probably have blown up a long time ago if it had some anomaly/defect in the tube. I would like to see the baffles but I'm guessing the ones behind the crack were deformed by the blast, indicating there was some kind of obstruction blocking a baffle hole. Creating a bomb with Hoppe's 9 or some other flammable solvent might also explain it.

A 5 year old YMH is not going to be shy of wall-thickness. They are nothing if not stout. I also think it would probably have blown up a long time ago if it had some anomaly/defect in the tube. I would like to see the baffles but I'm guessing the ones behind the crack were deformed by the blast, indicating there was some kind of obstruction blocking a baffle hole. Creating a bomb with Hoppe's 9 or some other flammable solvent might also explain it.

Moose,

Did your friend call YHM? I am very interested in finding out what they say.

He did call but they are closed right now.

He is a kinda crappy pic of the baffles. They look good. No baffle strikes.

Hope they can get it straight. Wonder how long they will be closed?

That’s true. Wonder if it cracked or deformed the baffles next to the tube?I don't think you will know the condition of the baffles until they are removed.

Couldn't they just enscribe the same serial in the new supressor and destroy the defective one?

Yea, you can thank Gemtech for this jacked up repair process, and to a lessor extent AAC since they were the instigators of this mess. Research the term "gemtax" and you can draw your own conclusions. Basically daddy ATF got tired of the kids fighting and whining and punished all of them, even the ones who had nothing to do with it and were behaving. Typical government letter agency FUBAR solution decree. BS that bypasses what should have been legislation from congress, not an agency definition ruling.NO! Not allowed.

Any metal is weaker where its thickness is reduced, as by engraving. They allow for that by keeping the engraving shallow and the wall-thickness up.

A 5 year old YMH is not going to be shy of wall-thickness. They are nothing if not stout. I also think it would probably have blown up a long time ago if it had some anomaly/defect in the tube. I would like to see the baffles but I'm guessing the ones behind the crack were deformed by the blast, indicating there was some kind of obstruction blocking a baffle hole. Creating a bomb with Hoppe's 9 or some other flammable solvent might also explain it.

I don't think so, looks like fatigue at a stress riser in the engraving. Fatigue will not necessarily present right away, but it's still a YHM problem and they should fix it.

Also, what's this about Hoppes 9 blowing up cans, I've never heard that, must be what happened to all those Crux cans that blew out at the engraving!

I don't think so, looks like fatigue at a stress riser in the engraving. Fatigue will not necessarily present right away, but it's still a YHM problem and they should fix it.

Also, what's this about Hoppes 9 blowing up cans, I've never heard that, must be what happened to all those Crux cans that blew out at the engraving!

If you take a perfectly good, heavy-walled can and over-pressurize it until the wall fails, it will fail at the engraving every time, because that spot is weaker than the surrounding material. It does not mean there was anything wrong with the can or its engraving, that is just how over-stressed metal works.

Crux utilized a defective design -- the engraving reached too deeply into the walls of many of its cans.

As for the Hoppes, I have no idea if Hoppes was ever even used on the can, or any other solvent, but I do know that there are many substances which will explode with tremendous force in their vapor form. Throw a match into a bucket of gasoline and all you get is a fire. Throw a match into a tank with gasoline (or even just sewage) vapors and you will get an explosion that will hurl your dead body 50 feet. Same thing with fertilizer -- you can hardly get a cup of it to burn but fill a silo with its dust and introduce a flame and you will get one hell of an explosion.

Just because you have never heard of a phenomenon does not mean it does not exist.

The issue with Hoppes is not so much with Hoppes but with any liquid whether flammable or not. The high temp powder gas will turn whatever liquid is left inside the can to vapor pretty quickly and can increase the pressure by a lot. Water turns to steam and even oils turn to vapor. So if you clean your suppressor or use it for a solvent trap leaving liquid inside it can lead to a burst can if things are already marginal.

Rifle caliber cans are frequently toward the marginal end because guys don't want heavy cans on their rifles. Add in the engraving which reduces wall thickness and a little internal corrosion or erosion and pop, the can splits. Gemtech had some issues with a couple models of suppressors where they discovered the engraving was creating stress risers that failed too often to be luck. At the time they were still a good company and took care of things. Later on they kind of turned into an AAC type company where customer service was a dream rather than a reality. Then S&W bought them and turned them into a ????? Not really sure what they turned into.

Pistol caliber cans seldom build enough pressure or heat to reduce the strength of the material they're made of. They're usually overbuilt too so running ablatives in pistol cans is a common thing to do to reduce sound levels. The same is not true of rifle cal cans. I've seen guys squirt oil or other stuff into their high dollar poor quality suppressors to try and get some semblance of sound reduction but its a really bad idea. I've seen a few split or scattered cans from the practice too.

Tubes can't be legally replaced without a new transfer anymore. As someone farther up noted the atf decided they were being cut out of cash by allowing manufacturers to do what the regs allowed. They told us for a long time we could replace damaged tubes with a new tube using the same serial number as long as the original was destroyed and only the original manufacturer could do it. The same was true of receivers. Olympia started replacing AR receivers made by other companies during the assault weapons ban and this started the downhill slide that lead to cans being restricted too. If you have to shorten the can to repair it you can only remove 20% or less. They came up with some other silly stuff too but I can't recall it all....

OP is going to probably have to do a new transfer whether YHM will warranty the can or not.

Frank

Rifle caliber cans are frequently toward the marginal end because guys don't want heavy cans on their rifles. Add in the engraving which reduces wall thickness and a little internal corrosion or erosion and pop, the can splits. Gemtech had some issues with a couple models of suppressors where they discovered the engraving was creating stress risers that failed too often to be luck. At the time they were still a good company and took care of things. Later on they kind of turned into an AAC type company where customer service was a dream rather than a reality. Then S&W bought them and turned them into a ????? Not really sure what they turned into.

Pistol caliber cans seldom build enough pressure or heat to reduce the strength of the material they're made of. They're usually overbuilt too so running ablatives in pistol cans is a common thing to do to reduce sound levels. The same is not true of rifle cal cans. I've seen guys squirt oil or other stuff into their high dollar poor quality suppressors to try and get some semblance of sound reduction but its a really bad idea. I've seen a few split or scattered cans from the practice too.

Tubes can't be legally replaced without a new transfer anymore. As someone farther up noted the atf decided they were being cut out of cash by allowing manufacturers to do what the regs allowed. They told us for a long time we could replace damaged tubes with a new tube using the same serial number as long as the original was destroyed and only the original manufacturer could do it. The same was true of receivers. Olympia started replacing AR receivers made by other companies during the assault weapons ban and this started the downhill slide that lead to cans being restricted too. If you have to shorten the can to repair it you can only remove 20% or less. They came up with some other silly stuff too but I can't recall it all....

OP is going to probably have to do a new transfer whether YHM will warranty the can or not.

Frank

Okay then, stupid question for the engineering-interested: Why are they engraved?

No I don't mean why does ATF require engraving, but why engrave on the tube directly? Would it be implausible to have, say... a small thicker area — machined or or welded on — for a dataplate that could take the engraving without sacrificing strength? Or something?

No I don't mean why does ATF require engraving, but why engrave on the tube directly? Would it be implausible to have, say... a small thicker area — machined or or welded on — for a dataplate that could take the engraving without sacrificing strength? Or something?

Its engraved because the regs say you have to. I don't know if they would allow a welded or soldered plate but it may be possible. Thick areas and added plates add to manufacturing costs and difficulty so that is probably a good reason why they don't do that part.

The engraving problem as I see it is that the makers feel a need to use their logo or some elaborate design that can create the problem when tubing thickness is reduced to the minimum for weight savings. Material has a lot to do with it too. Titanium doen't like notches and cuts and alloy steels don't either. A lot of older cans were much thicker than necessary or made from material that was less sensitive to stress risers. Some manufacturers keep the problem in mind and engrave the muzzle end of the tube rather than the middle. This keeps the weak area in a place where stresses and heat are lower. So the main reason for these current failures is due to marketing guys deciding the markings need to be in the middle and must have elaborate designs.

Just my opinion of course but looking at the failures it appears to be true.

Frank

The engraving problem as I see it is that the makers feel a need to use their logo or some elaborate design that can create the problem when tubing thickness is reduced to the minimum for weight savings. Material has a lot to do with it too. Titanium doen't like notches and cuts and alloy steels don't either. A lot of older cans were much thicker than necessary or made from material that was less sensitive to stress risers. Some manufacturers keep the problem in mind and engrave the muzzle end of the tube rather than the middle. This keeps the weak area in a place where stresses and heat are lower. So the main reason for these current failures is due to marketing guys deciding the markings need to be in the middle and must have elaborate designs.

Just my opinion of course but looking at the failures it appears to be true.

Frank

Ah, I was assuming a different material was fine if not easily removable because: Plastic guns with their embedded serial plate. I believe costs, etc.

More nerd questions: So would stamped info — instead of engraved — retain more of the strength of the substrate? Stamping and casting are also allowed methods, doesn't have to be engraved per se. (§ 479.102 a 1 "By engraving, casting, stamping (impressing),..." )

More nerd questions: So would stamped info — instead of engraved — retain more of the strength of the substrate? Stamping and casting are also allowed methods, doesn't have to be engraved per se. (§ 479.102 a 1 "By engraving, casting, stamping (impressing),..." )

Last edited:

If you take a perfectly good, heavy-walled can and over-pressurize it until the wall fails, it will fail at the engraving every time, because that spot is weaker than the surrounding material. It does not mean there was anything wrong with the can or its engraving, that is just how over-stressed metal works.

Crux utilized a defective design -- the engraving reached too deeply into the walls of many of its cans.

As for the Hoppes, I have no idea if Hoppes was ever even used on the can, or any other solvent, but I do know that there are many substances which will explode with tremendous force in their vapor form. Throw a match into a bucket of gasoline and all you get is a fire. Throw a match into a tank with gasoline (or even just sewage) vapors and you will get an explosion that will hurl your dead body 50 feet. Same thing with fertilizer -- you can hardly get a cup of it to burn but fill a silo with its dust and introduce a flame and you will get one hell of an explosion.

Just because you have never heard of a phenomenon does not mean it does not exist.

I did my PE in materials and machine design, I have some familiarity with stress, metals, fatigue, etc. I'm not saying it's impossible that the OP squirted some flammable liquid in his can and blew it up, but I don't think it's likely, and it's certainly not the simplest explanation.

The simplest explanation to me would be that the stress risers from the engraving, be it as designed, or maybe cut a bit deeper than intended, possibly in conjunction with a flaw, or inclusion, etc caused the localized stress to rise above the fatigue strength of the material leading to a low cycle fatigue failure. Just because something survives the first several hundred or thousand cycles doesn't mean that when it breaks on cycle 1,001, the failure isn't the product of a problem in design or manufacture... The entire fields of study on fatigue and fracture mechanics are built around this reality.

So your supposition could be correct, that the OP put a bunch of flammable liquid in the can and happened to hit the right fuel air mixture to cause a detonation (usually has to be fairly well controlled at a certain mixture if you want an actual fuel-air detonation), but I don't think so. I think the picture very likely shows the product of fatigue and a manufacturer defect as I said above. Speculation along the lines of "YHM usually makes heavy cans so the wall on this can is probably pretty thick" don't really do much to change my thought process on this. I also think YHM will probably cover this under warranty, although it may still involve the OP waiting on another stamp.

OP, can you clear up the issue, did you squirt a flammable liquid in your can prior to this kaboom?

Edit: Whups, forgot the can actually belongs to the OP's buddy, not the OP himself.

Last edited:

Yes I can clarify that not cleaning solvent entered into the suppressor before the kaboom. He always cleans the gun with the suppressor off the rifle and has not tried to clean the suppressor him self.

You engineers, they never teach you to read. I did not "suppose" anything. I just pointed out that there were more possible explanations than simply "engraving stress-points.". OP's friend says no way on the solvent, but that still leaves a possible obstruction in the can.

I point this out because YHM has been making suppressors for many years, and I find it a little difficult to believe that 5 years ago, when this can was made, they suddenly screwed up and engraved it too deeply. Certainly possible, perhaps even the most probable, but there are other possibilities.

I point this out because YHM has been making suppressors for many years, and I find it a little difficult to believe that 5 years ago, when this can was made, they suddenly screwed up and engraved it too deeply. Certainly possible, perhaps even the most probable, but there are other possibilities.

I did my PE in materials and machine design, I have some familiarity with stress, metals, fatigue, etc. I'm not saying it's impossible that the OP squirted some flammable liquid in his can and blew it up, but I don't think it's likely, and it's certainly not the simplest explanation.

The simplest explanation to me would be that the stress risers from the engraving, be it as designed, or maybe cut a bit deeper than intended, possibly in conjunction with a flaw, or inclusion, etc caused the localized stress to rise above the fatigue strength of the material leading to a low cycle fatigue failure. Just because something survives the first several hundred or thousand cycles doesn't mean that when it breaks on cycle 1,001, the failure isn't the product of a problem in design or manufacture... The entire fields of study on fatigue and fracture mechanics are built around this reality.

So your supposition could be correct, that the OP put a bunch of flammable liquid in the can and happened to hit the right fuel air mixture to cause a detonation (usually has to be fairly well controlled at a certain mixture if you want an actual fuel-air detonation), but I don't think so. I think the picture very likely shows the product of fatigue and a manufacturer defect as I said above. Speculation along the lines of "YHM usually makes heavy cans so the wall on this can is probably pretty thick" don't really do much to change my thought process on this. I also think YHM will probably cover this under warranty, although it may still involve the OP waiting on another stamp.

OP, can you clear up the issue, did you squirt a flammable liquid in your can prior to this kaboom?

Edit: Whups, forgot the can actually belongs to the OP's buddy, not the OP himself.

You engineers, they never teach you to read. I did not "suppose" anything. I just pointed out that there were more possible explanations than simply "engraving stress-points.". OP's friend says no way on the solvent, but that still leaves a possible obstruction in the can.

I point this out because YHM has been making suppressors for many years, and I find it a little difficult to believe that 5 years ago, when this can was made, they suddenly screwed up and engraved it too deeply. Certainly possible, perhaps even the most probable, but there are other possibilities.

they have been making cans forever and yet they are not very popular. This isn’t 2005 anymore and people don’t buy YHM. Take that YHM and put it on a Larue so you can go retro.

No need for flammable material to be used. Anything can be vaporized and thus increase the internal pressure. An ignition is a really unlikely thing due to the reduced oxygen content in the powder gas. This is demonstrated frequently by the muzzle flash that shows up. Most of the flash is due to hydrogen and carbon monoxide in the gasses mixing with oxygen in the atmosphere at a temperature above the ignition point.

You're right on about the engraving and the failures though. Over pressure will find the weakest point to start the failure.

It is quite possible that stamped markings would be less likely to cause cracks but the real failure is parts designed too close to the limits encountered in my opinion. Older cans didn't seem to have the frequency of failures that newer ones do. I think its because they're trying to reduce weight to the minimum. Its a big selling point to have a few grams less weight than the competition. Sound reduction seems to be less important now too. Marketers are designing the cans by forcing designers to do stuff not necessarily improving performance but rather improving looks or cool factor. One of these important factors is weight. Less weight reduces durability though so keep this in mind. Seeing some of the warnings that were included with titanium rifle suppressors a few years ago was an education. "Do not fire more than one shot per minute up to a total of 10 shots in 10 minutes. After that the suppressor should be allowed to cool for 10 minutes." For a hunting rifle on a hunt its not a big deal to do that. For the average Joe who wants to shoot his AR it makes no sense. I've had a couple cans come through the shop where the owners didn't read the notice til after they popped the can. Ti doesn't transfer heat well and it weakens quickly as the temp goes up. Not saying the OP did anything wrong. First shot pops shouldn't happen unless you're running your 223 can on your 338 Lapua. Just things to consider...

Frank

You're right on about the engraving and the failures though. Over pressure will find the weakest point to start the failure.

It is quite possible that stamped markings would be less likely to cause cracks but the real failure is parts designed too close to the limits encountered in my opinion. Older cans didn't seem to have the frequency of failures that newer ones do. I think its because they're trying to reduce weight to the minimum. Its a big selling point to have a few grams less weight than the competition. Sound reduction seems to be less important now too. Marketers are designing the cans by forcing designers to do stuff not necessarily improving performance but rather improving looks or cool factor. One of these important factors is weight. Less weight reduces durability though so keep this in mind. Seeing some of the warnings that were included with titanium rifle suppressors a few years ago was an education. "Do not fire more than one shot per minute up to a total of 10 shots in 10 minutes. After that the suppressor should be allowed to cool for 10 minutes." For a hunting rifle on a hunt its not a big deal to do that. For the average Joe who wants to shoot his AR it makes no sense. I've had a couple cans come through the shop where the owners didn't read the notice til after they popped the can. Ti doesn't transfer heat well and it weakens quickly as the temp goes up. Not saying the OP did anything wrong. First shot pops shouldn't happen unless you're running your 223 can on your 338 Lapua. Just things to consider...

Frank

Gemtax created this ruling with ATF.

NO! Not allowed.

I did my PE in materials and machine design, I have some familiarity with stress, metals, fatigue, etc. I'm not saying it's impossible that the OP squirted some flammable liquid in his can and blew it up, but I don't think it's likely, and it's certainly not the simplest explanation.

The simplest explanation to me would be that the stress risers from the engraving, be it as designed, or maybe cut a bit deeper than intended, possibly in conjunction with a flaw, or inclusion, etc caused the localized stress to rise above the fatigue strength of the material leading to a low cycle fatigue failure. Just because something survives the first several hundred or thousand cycles doesn't mean that when it breaks on cycle 1,001, the failure isn't the product of a problem in design or manufacture... The entire fields of study on fatigue and fracture mechanics are built around this reality.

So your supposition could be correct, that the OP put a bunch of flammable liquid in the can and happened to hit the right fuel air mixture to cause a detonation (usually has to be fairly well controlled at a certain mixture if you want an actual fuel-air detonation), but I don't think so. I think the picture very likely shows the product of fatigue and a manufacturer defect as I said above. Speculation along the lines of "YHM usually makes heavy cans so the wall on this can is probably pretty thick" don't really do much to change my thought process on this. I also think YHM will probably cover this under warranty, although it may still involve the OP waiting on another stamp.

OP, can you clear up the issue, did you squirt a flammable liquid in your can prior to this kaboom?

Edit: Whups, forgot the can actually belongs to the OP's buddy, not the OP himself.

Improperly purged atmosphere during the laser engraving process.

they have been making cans forever and yet they are not very popular. This isn’t 2005 anymore and people don’t buy YHM. Take that YHM and put it on a Larue so you can go retro.

YHM is one of the single most popular silencer brands in the US.

YHM is one of the single most popular silencer brands in the US.

And Bushmaster is one of the single most popular AR brands in the US. ........

The difference is that engineers tend to use evidence and experience to offer up potential failure modes. Like the picture showing that the failure was clearly at the engraving stressor. Others like yourself would like to make up unlikely possibilities not supported by the evidence on front of them.You engineers, they never teach you to read. I did not "suppose" anything. I just pointed out that there were more possible explanations than simply "engraving stress-points.". OP's friend says no way on the solvent, but that still leaves a possible obstruction in the can.

The fact that YHM has been making suppressors for years means nothing, unless you consider that the more product a manufacturer makes increases the likelihood that the variations inherent in the manufacturing process will eventually produce a can with a better chance for failure.I point this out because YHM has been making suppressors for many years, and I find it a little difficult to believe that 5 years ago, when this can was made, they suddenly screwed up and engraved it too deeply. Certainly possible, perhaps even the most probable, but there are other possibilities.

It’s not necessarily a slam of YHM that they had a failure. However, it’s an opportunity for them to do a thorough analysis of the materials, process and tolerances used in their manufacture. Whether they see that opportunity and take it will tell a lot about them as a company.

I have a preban bushmaster that has close to 20000 rounds through it. In that time I replaced the gas key because it carboned up from not being cleaned. And the bolt broke a couple months ago. Carbine gas + a old suppressor + non AGB prolly contributed to that. Nothing wrong with bushmasterAnd Bushmaster is one of the single most popular AR brands in the US. ........

Last edited:

they have been making cans forever and yet they are not very popular. This isn’t 2005 anymore and people don’t buy YHM. Take that YHM and put it on a Larue so you can go retro.

YHM is selling the shit out the Turbo T2, Turbo K, and Resonator R2. I’d hazard a guess that the Turbo K is one of the top selling cans out there.

I’m waiting on stamps for 2 Turbo K’s. One is going to live and work on my PS90 SBR with whatever damn voodoo they’ve put in that can on it that makes it work so well on those rifles.

The difference is that engineers tend to use evidence and experience to offer up potential failure modes. Like the picture showing that the failure was clearly at the engraving stressor. Others like yourself would like to make up unlikely possibilities not supported by the evidence on front of them.

A real engineer will tell you that no matter how over-built a suppressor may be, with no matter how much wall-thickness in the tube, if you presssure-stress it to the point that it fails it will always fail at the engraving, because regardless of how strong it is, that is still the weakest point.

It’s not necessarily a slam of YHM that they had a failure. However, it’s an opportunity for them to do a thorough analysis of the materials, process and tolerances used in their manufacture. Whether they see that opportunity and take it will tell a lot about them as a company.

You keep talking as if YHM must have had a flaw in the design or manufacture of that can, but you're the one jumping to "possibilities not supported by the evidence." Every YHM suppressor I have seen was nothing if not stout. They are heavier than most of your more popular cans because of that stoutness, including wall-thickness.

In the "Do you clean your suppressor?" thread there are several people who have described, when they finally got around to cleaning their suppressor, getting big chunks of carbon out of them and . . . here is the key . . . some could hardly fit them through the (bigger) threaded hole. That is a prescription for blockage of a baffle or end-cap hole that could easily account for the rupture of the YHM can, just as a small amount of snow has accounted for the rupture of hundreds of rifle barrels. As one gunsmith I know puts it -- "it is surprising how little snow it takes make a barrel blow up."

Now, of course, all the people here selling sealed cans and their sycophants will scream that that is just ridiculous blah, blah, blah, but it is not -- just ask any experienced, non-affiliated gunsmith if "big chunks of carbon" could cause a can to blow up.

That is just one more reason I will not even consider buying another non-user-serviceable can.

Last edited:

So, are you a “real engineer?” Because you sound like you are reaching and guessing.A real engineer will tell you that no matter how over-built a suppressor may be, with no matter how much wall-thickness in the tube, if you presssure-stress it to the point that it fails it will always fail at the engraving, because regardless of how strong it is, that is still the weakest point.

You keep talking as if YHM must have had a flaw in the design or manufacture of that can, but you're the one jumping to "possibilities not supported by the evidence." Every YHM suppressor I have seen was nothing if not stout. They are heavier than most of your more popular cans because of that stoutness, including wall-thickness.

In the "Do you clean your suppressor?" thread there are several people who have described, when they finally got around to cleaning their suppressor, getting big chunks of carbon out of them and . . . here is the key . . . some could hardly fit them through the (bigger) threaded hole. That is a prescription for blockage of a baffle or end-cap hole that could easily account for the rupture of the YHM can, just as a small amount of snow has accounted for the rupture of hundreds of rifle barrels. As one gunsmith I know puts it -- "it is surprising how little snow it takes make a barrel blow up."

Now, of course, all the people here selling sealed cans and their sycophants will scream that that is just ridiculous blah, blah, blah, but it is not -- just ask any experienced, non-affiliated gunsmith if "big chunks of carbon" could cause a can to blow up.

That is just one more reason I will not even consider buying another non-user-serviceable can.

I, on the other hand, am using the reality of statistical analysis known by any manufacturer. Even a capable design and manufacturing process will eventually produce an outlier that will fail. That is a fact and not guessing.

You are manufacturing possibilities and straw man arguments, even after being told that the owner of said can did none of the things you’re projecting. You are coming off as a big fanboi whether you mean to or not.

I never indicated that YHM produced inferior products or designs. You would do well to take your own advice and learn how to read. That is unless you are a real engineer and then you probably don’t know how, per your own words.

Similar threads

- Replies

- 24

- Views

- 1K

- Replies

- 28

- Views

- 460

- Replies

- 27

- Views

- 866