Hello,

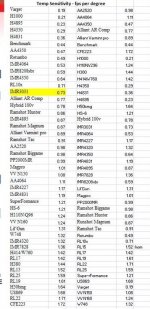

I am seeking the max powder charge to find out where the pressure signs start to show. Mostly to see how far off my charge is from unsafe. I also want to then compare the loads done in the summer to get a feeling of how many grains are needed to drop from winter loads to summer for future reference. I will make one load for all weather since that is maybe the strong side of N140 in addition to good accuracy.

My gun is MR223, it probably has 556 chamber.

I have already loaded 70gr VLD to 25.8gr of N140 and had very slight primer flattening in . I now loaded few 25.9, 26.1 and 26.2gr loads to see where it starts to show. Do you have any idea how far off I need to go? I doubt I will make ammo with more than 25.8 in it as it gets quite compressed beyond that and I want also to not weight the charges, just throw them.

I do not think that going higher than 26.2 is necessary for testing if I settle at 25.6 and some of the throws might stretch to 25.8? How much do you estimate I will have to drop the charge by for the 100F temperatures if at all?

I will not be shooting 70VLD much more, I am switching to scenars but this same issue still stands.

In short:

How pressure/charge aware should I be, considering variance from throwing and temperature?

I am seeking the max powder charge to find out where the pressure signs start to show. Mostly to see how far off my charge is from unsafe. I also want to then compare the loads done in the summer to get a feeling of how many grains are needed to drop from winter loads to summer for future reference. I will make one load for all weather since that is maybe the strong side of N140 in addition to good accuracy.

My gun is MR223, it probably has 556 chamber.

I have already loaded 70gr VLD to 25.8gr of N140 and had very slight primer flattening in . I now loaded few 25.9, 26.1 and 26.2gr loads to see where it starts to show. Do you have any idea how far off I need to go? I doubt I will make ammo with more than 25.8 in it as it gets quite compressed beyond that and I want also to not weight the charges, just throw them.

I do not think that going higher than 26.2 is necessary for testing if I settle at 25.6 and some of the throws might stretch to 25.8? How much do you estimate I will have to drop the charge by for the 100F temperatures if at all?

I will not be shooting 70VLD much more, I am switching to scenars but this same issue still stands.

In short:

How pressure/charge aware should I be, considering variance from throwing and temperature?