The topic comes up ever so many months and you'll find quite a lot of people will chime in with the blind "you shouldn't have to bed a chassis" line. The recent "what the pros use" chassis article from Precision Rifle Blog revealed some numbers I think many will find surprising. Before getting into the article, let's get one point out of the way:

For that to be a universal truth (chassis should not require bedding), it would mean that any chassis that requires bedding to remove something like a zero shift.......is by default a defective chassis. But, you'll find that most of the time when a chassis requires bedding that it is easily within manufacturing specs and all but identical to a chassis of the same brand that doesn't require bedding. So, you can't have it both ways. Either chassis are subject to bedding when needed, or chassis requiring bedding must be defective.

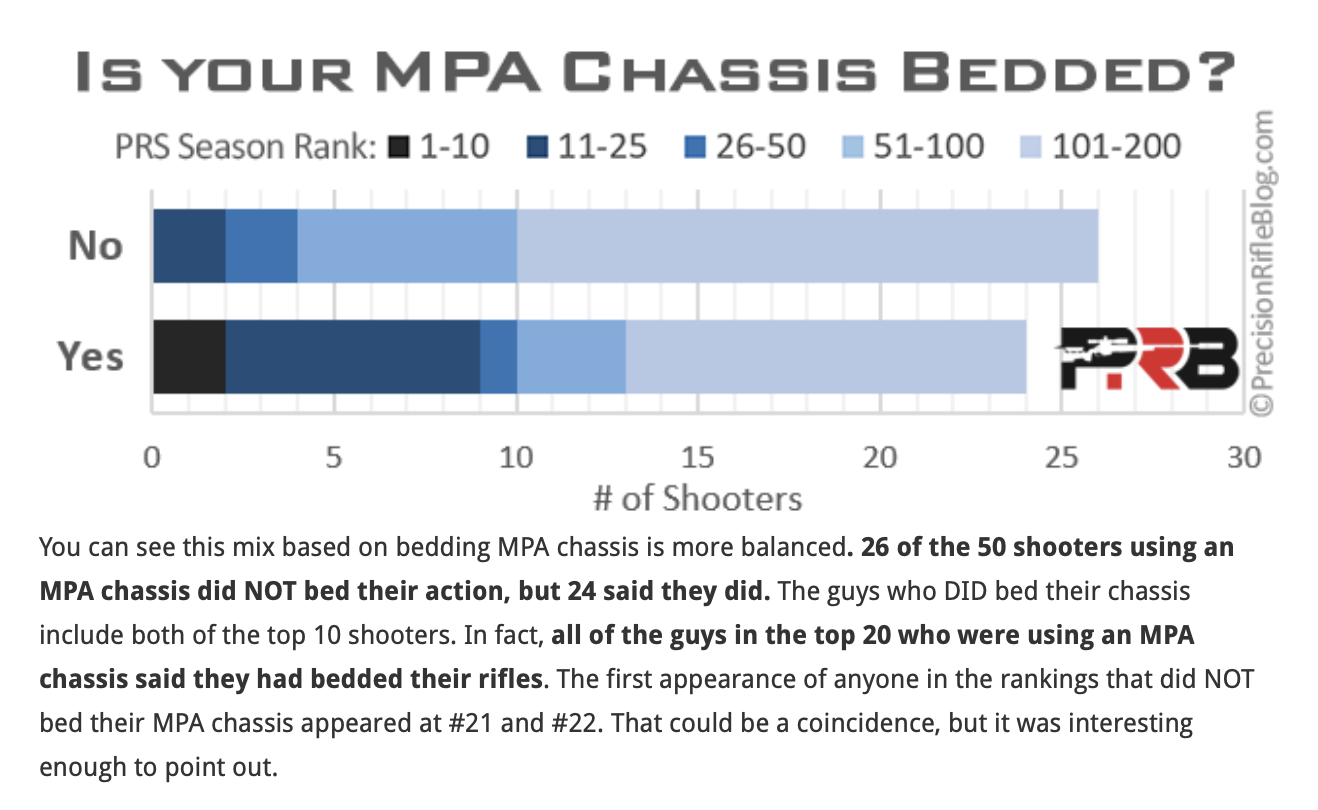

Here is a screenshot from the article pertaining to MPA. There were 50 shooters in the top 200 using an MPA chassis of some sort. Just shy of 50% of those 50 shooters have their chassis bedded. Everyone in the top 20 with an MPA chassis reported their chassis to be bedded.

The TLDR version: it's impossible for universal fit bedding areas will match up to every action enough that bedding will never be required by a properly machined chassis.

It's perfectly fine not to bed a chassis. However, I'd encourage anyone who insists you shouldn't have to bed a chassis to take some time and either rationally reevaluate your opinion, or do some impact testing on various chassis (you'll find that many will experience some zero shift of some sort).

For that to be a universal truth (chassis should not require bedding), it would mean that any chassis that requires bedding to remove something like a zero shift.......is by default a defective chassis. But, you'll find that most of the time when a chassis requires bedding that it is easily within manufacturing specs and all but identical to a chassis of the same brand that doesn't require bedding. So, you can't have it both ways. Either chassis are subject to bedding when needed, or chassis requiring bedding must be defective.

Here is a screenshot from the article pertaining to MPA. There were 50 shooters in the top 200 using an MPA chassis of some sort. Just shy of 50% of those 50 shooters have their chassis bedded. Everyone in the top 20 with an MPA chassis reported their chassis to be bedded.

The TLDR version: it's impossible for universal fit bedding areas will match up to every action enough that bedding will never be required by a properly machined chassis.

It's perfectly fine not to bed a chassis. However, I'd encourage anyone who insists you shouldn't have to bed a chassis to take some time and either rationally reevaluate your opinion, or do some impact testing on various chassis (you'll find that many will experience some zero shift of some sort).