It amazing what setting up your dies correctly can do for you. If you recall, I had some issues recently with Lapua brass failing and significant pressure signs with what should have been normal loads and it turned out to be incorrect headspace (read here).

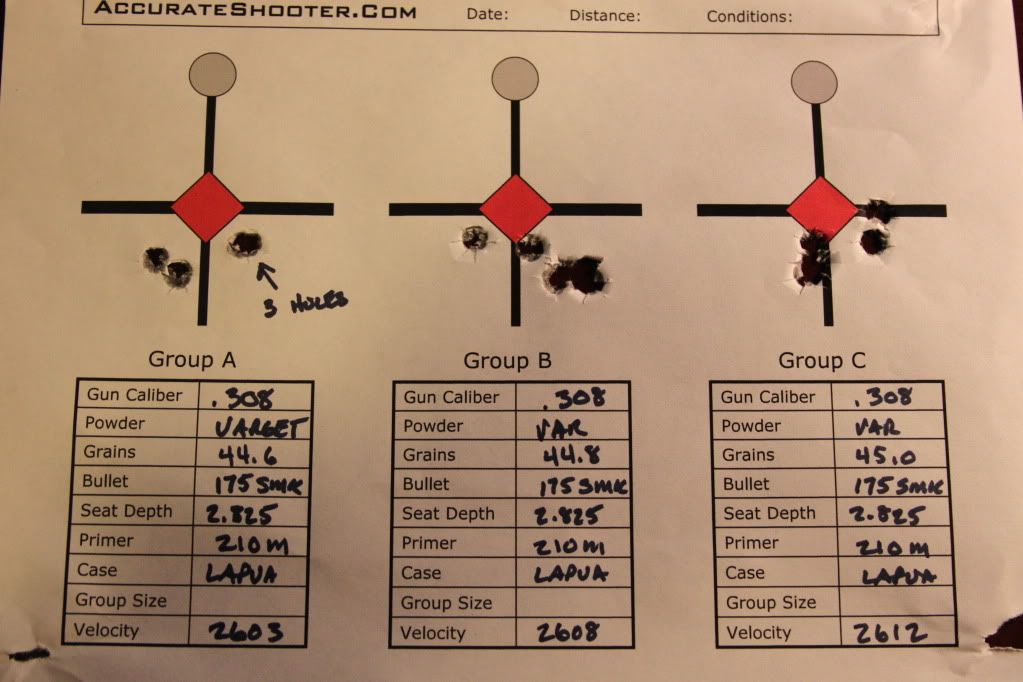

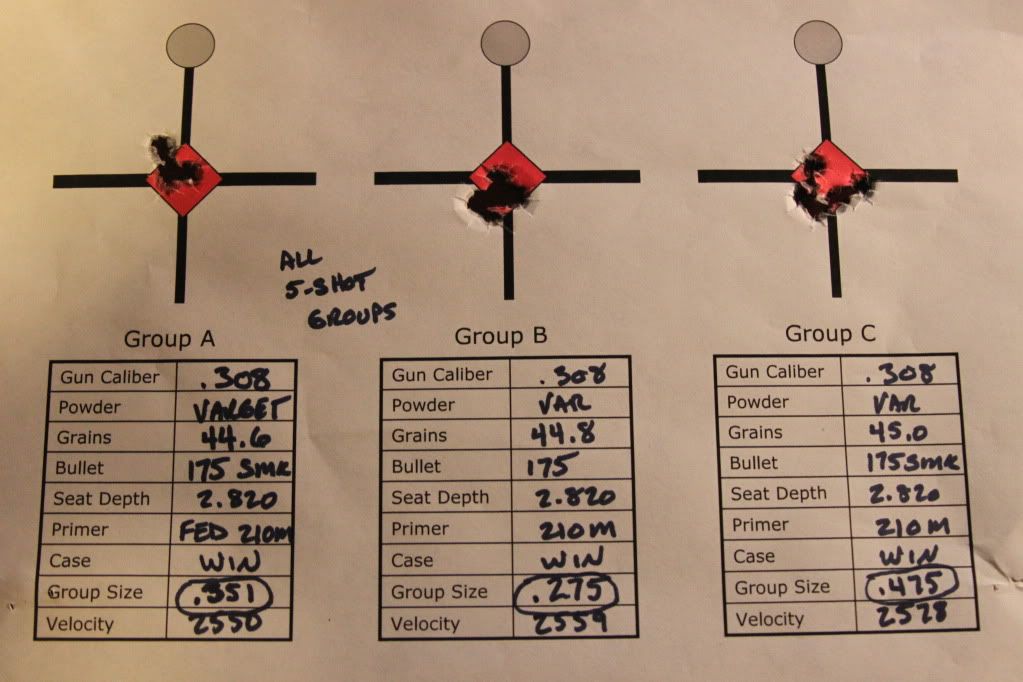

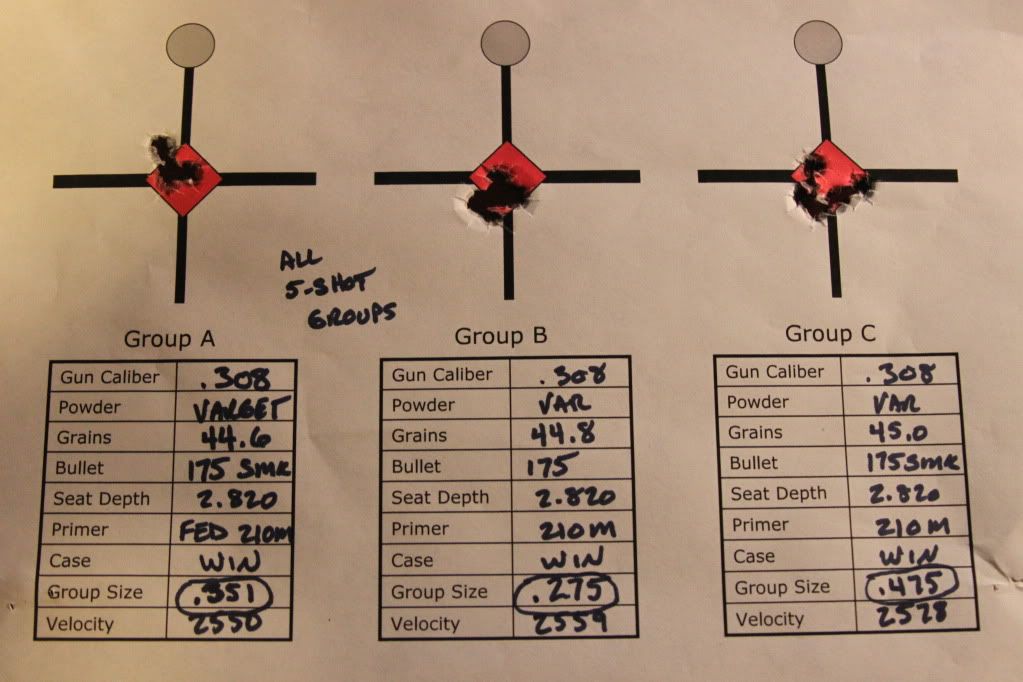

So I found some promising loads after going back and resetting up my FL sizing die using Doc's instructions to get the headspace correct for my new chamber. So I went out and re-shot some loads across the chrono today and got these results:

Upper left (44.6 Varget) is a cold clean bore.

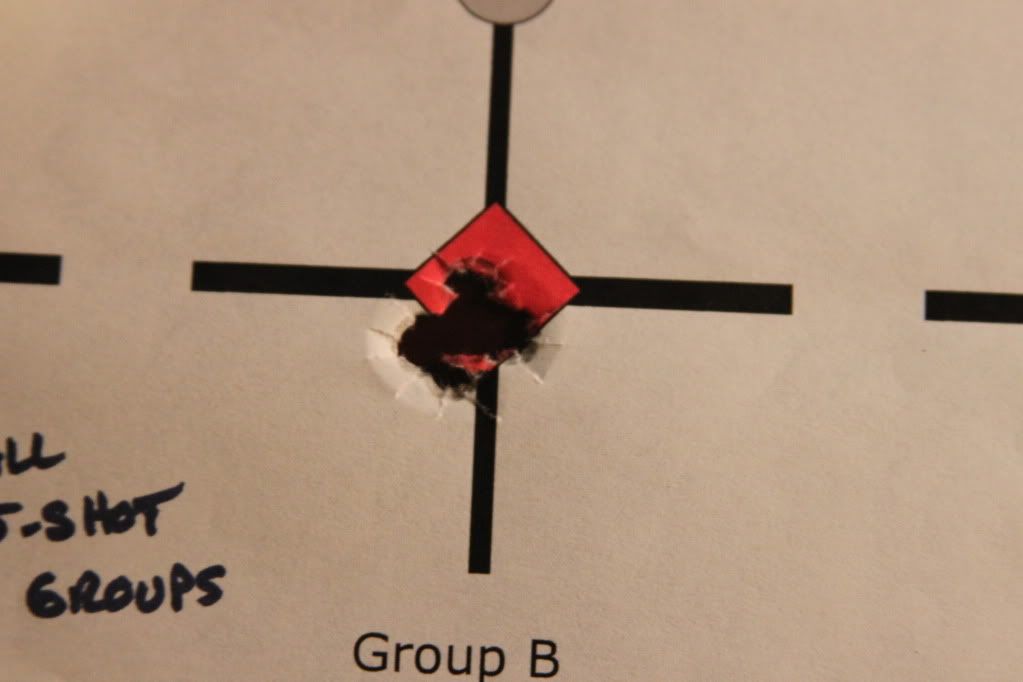

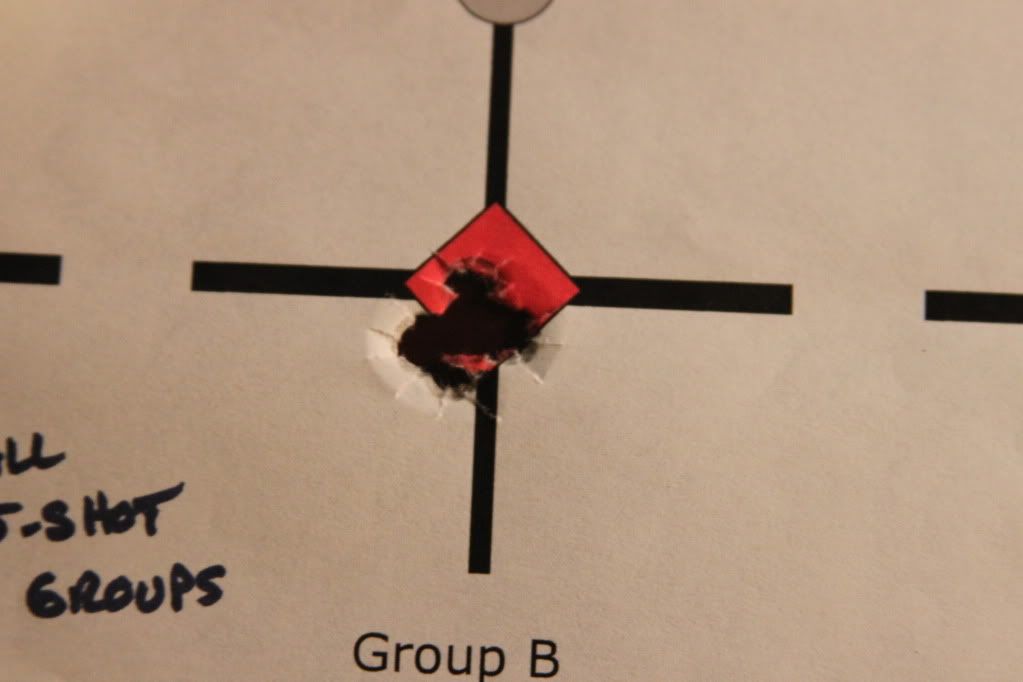

2nd group of the day was the best by far. Here's a closeup:

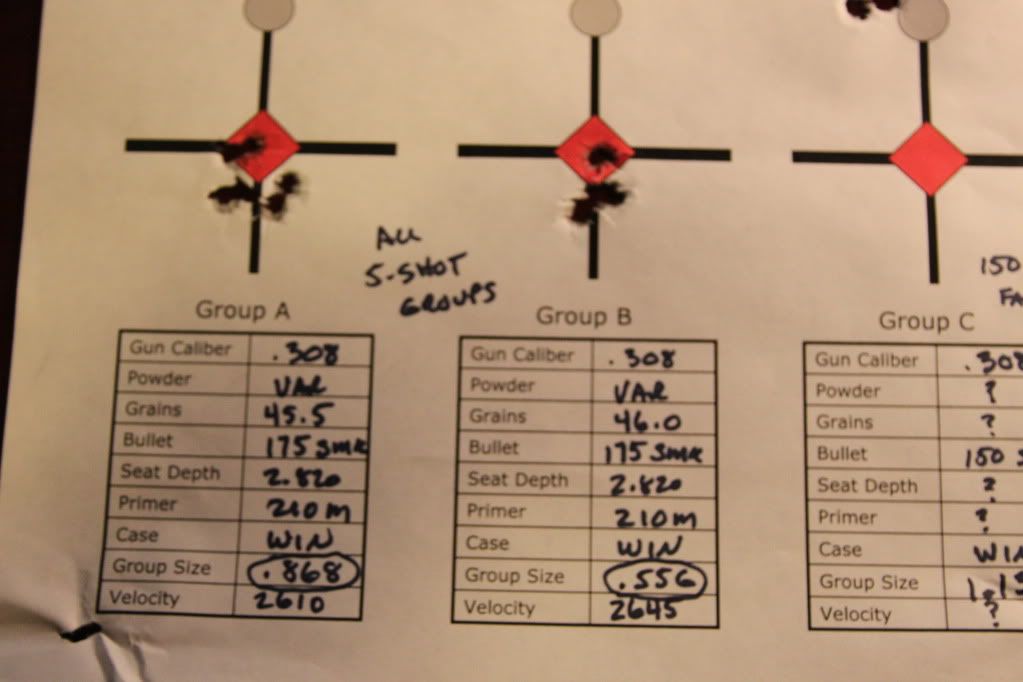

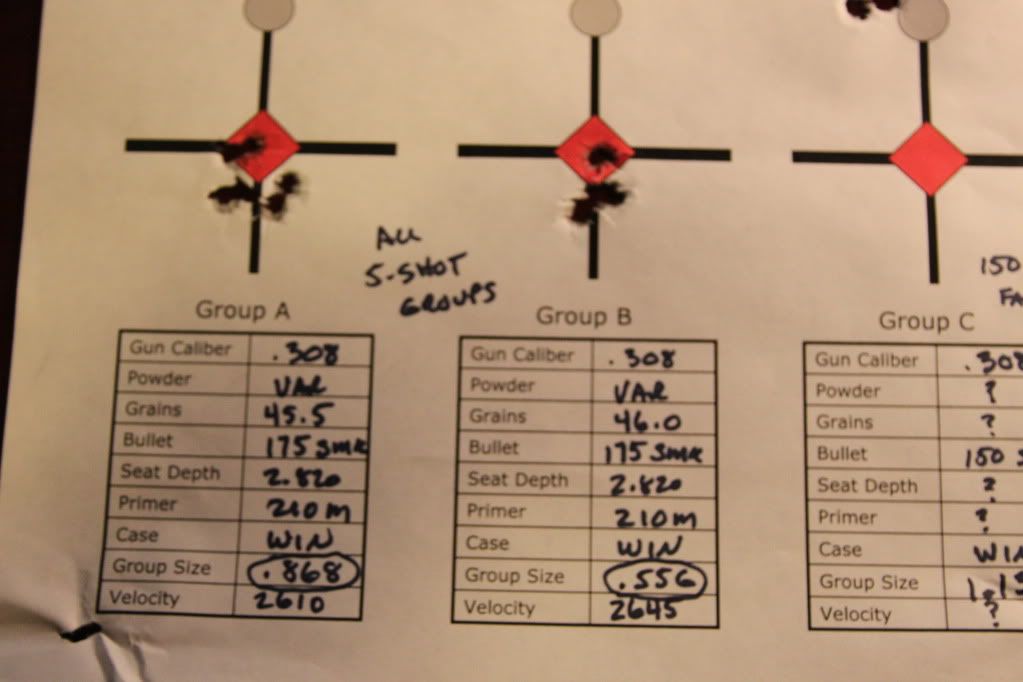

QL said I should be able to get up into the 2600's by going above 45.0 Varget/175SMK since I was using Win brass, so I tried a 45.5 and a 46.0. The plan was to stop the moment I got any pressure signs. But surprisingly even the 46.0 Varget/175SMK had no issues at all.

One thing that I did different this time as opposed to the times I was getting 1/2 to 3/4 MOA groups with the same load was I played with the neck tension a bit. On this batch of WIN brass, I tried two new tricks: 1) I neck sized the brass in two steps, 1st from .343 down to .339 and then I FL sized them with a .333 neck bushing which gave me very LIGHT neck tension. I think the .001 less neck tension really helped the accuracy. Thanks again to everyone for all the help and tips in my Lapua brass failed thread. Your help really got me back on track!

So I found some promising loads after going back and resetting up my FL sizing die using Doc's instructions to get the headspace correct for my new chamber. So I went out and re-shot some loads across the chrono today and got these results:

Upper left (44.6 Varget) is a cold clean bore.

2nd group of the day was the best by far. Here's a closeup:

QL said I should be able to get up into the 2600's by going above 45.0 Varget/175SMK since I was using Win brass, so I tried a 45.5 and a 46.0. The plan was to stop the moment I got any pressure signs. But surprisingly even the 46.0 Varget/175SMK had no issues at all.

One thing that I did different this time as opposed to the times I was getting 1/2 to 3/4 MOA groups with the same load was I played with the neck tension a bit. On this batch of WIN brass, I tried two new tricks: 1) I neck sized the brass in two steps, 1st from .343 down to .339 and then I FL sized them with a .333 neck bushing which gave me very LIGHT neck tension. I think the .001 less neck tension really helped the accuracy. Thanks again to everyone for all the help and tips in my Lapua brass failed thread. Your help really got me back on track!