1st a little background (then my problem):

I just got my AR15 recently and unfortunately the range is only open ONE day a week so load development is rediculously slow.

Heres the rifle, Bushmaster Upper 24" Varmint HVY match barrel, LAR grizzly Lower w/ RRA LPK, Stark E-2 grip, Nikon Buckmaster 6-18x scope, Primary arms 1 piece scope mount.

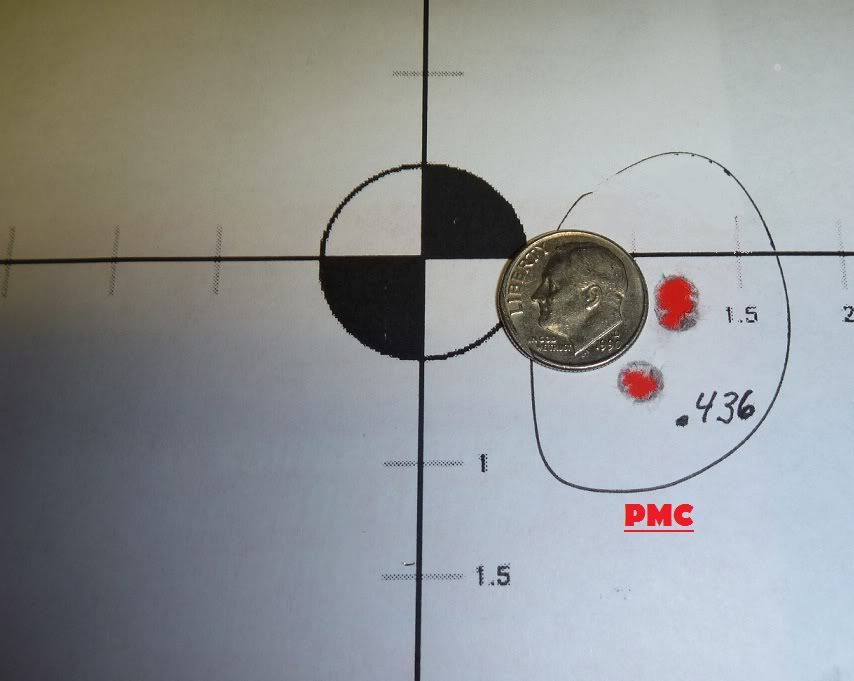

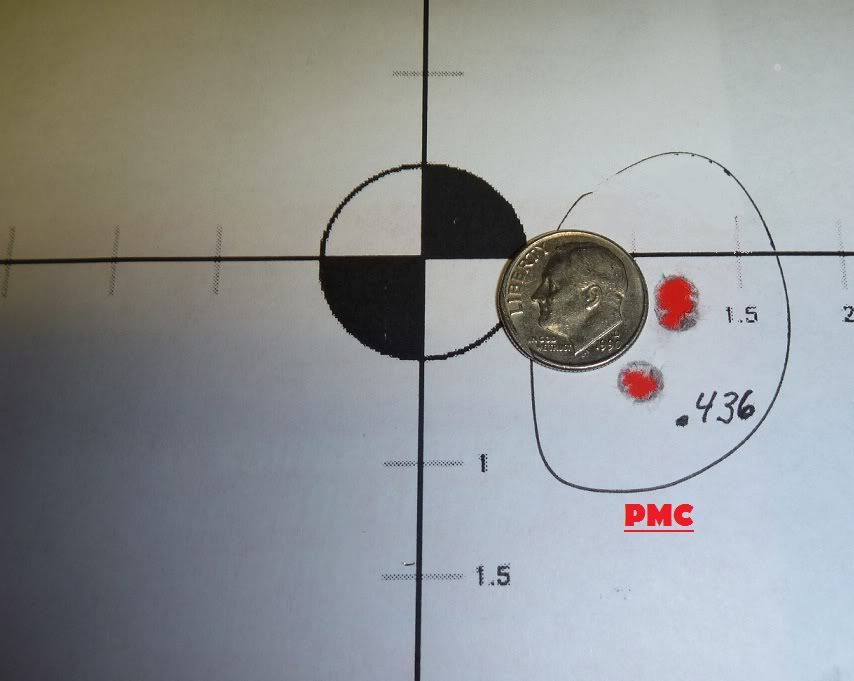

Anyway, the 1st trip to the range was using several brands of factory amo just to see how the gun shot. Here are the four best 100yd groups.

Everything else shot .75 or bigger so I didnt even bother with them. This was better than I had expected with off the shelf ammo even though th ereview I read had a 1/4" 100 yd group (with NICE ammo. I was very excited to think I could get sub .5 moa with factory ammo. I couldnt wait to try out some nice reloads.

I have searched everywhere I could find for best loads for the AR15 223. I found several and decided to try 6 of them for the 1st test run using 50gr sierra blitzkings? (green tips),55gr vmax, and 69gr SMK's. I seated the bullets back off the lands a few thousands.

I have several brands of brass (range brass) sorted by brand but right now I dont rem which brand I used for these tests. I do know is was 223 brass not 5.56 brass.

When I 1st started to reload for this AR I used the standard RCBS FL die but noticed the bolt wouldnt copmpletely close on this brass if I closed the bolt slowly with the charging handle. It closes just fine on new factory ammo. My friend said he knew what the problem was. I needed a Small Base die. So I bought one and tried it.

The bras still wont close all the way if I close it slowly. Is that ok? If I just pull the bolt back and let go it slams the bolt closed just fine. but with factory ammo it closes fine even going slow. Is that normal?

I have the SB die just barely touching the shell holder to get the most I can from the die.

I measuered the factory brass and the only difference is the factory brass is .003-.004 smaller than the fully resized brass at the base. Length is right at 1.750, neck and shoulder measurements match the factory loads. just the base is off a few thousands. I'm assuming that is why the bolt wont close slowly all the way.

#1 - Is this something I should be worried about?

#2 - Does it have any effect on accuracy?

The reason I ask #2 is that I took my handloads to the range and they all 6 shot horribly. Not one group under 1". I was totaly diqusted. I dont know if i was just having a terrible day or the loads for some reason sucked in my gun even though MANY people claim they are the best loads theyve shot in their AR15's. The only 2 things I can think of are I need to find the right OAL and that the reloads dont feed a easily as the factory stuff.

I've used the SB die on several different brands of bras with the same results. I guess the bushmaster upper chamber just has very tight tolerances? But if I cant shoot reloads that are more accurate than cheap factory stuff with it I dont want it.

And ideas? Its supposed to rain all week so no range time this week it looks like.

frustrated,

Rodney

I just got my AR15 recently and unfortunately the range is only open ONE day a week so load development is rediculously slow.

Heres the rifle, Bushmaster Upper 24" Varmint HVY match barrel, LAR grizzly Lower w/ RRA LPK, Stark E-2 grip, Nikon Buckmaster 6-18x scope, Primary arms 1 piece scope mount.

Anyway, the 1st trip to the range was using several brands of factory amo just to see how the gun shot. Here are the four best 100yd groups.

Everything else shot .75 or bigger so I didnt even bother with them. This was better than I had expected with off the shelf ammo even though th ereview I read had a 1/4" 100 yd group (with NICE ammo. I was very excited to think I could get sub .5 moa with factory ammo. I couldnt wait to try out some nice reloads.

I have searched everywhere I could find for best loads for the AR15 223. I found several and decided to try 6 of them for the 1st test run using 50gr sierra blitzkings? (green tips),55gr vmax, and 69gr SMK's. I seated the bullets back off the lands a few thousands.

I have several brands of brass (range brass) sorted by brand but right now I dont rem which brand I used for these tests. I do know is was 223 brass not 5.56 brass.

When I 1st started to reload for this AR I used the standard RCBS FL die but noticed the bolt wouldnt copmpletely close on this brass if I closed the bolt slowly with the charging handle. It closes just fine on new factory ammo. My friend said he knew what the problem was. I needed a Small Base die. So I bought one and tried it.

The bras still wont close all the way if I close it slowly. Is that ok? If I just pull the bolt back and let go it slams the bolt closed just fine. but with factory ammo it closes fine even going slow. Is that normal?

I have the SB die just barely touching the shell holder to get the most I can from the die.

I measuered the factory brass and the only difference is the factory brass is .003-.004 smaller than the fully resized brass at the base. Length is right at 1.750, neck and shoulder measurements match the factory loads. just the base is off a few thousands. I'm assuming that is why the bolt wont close slowly all the way.

#1 - Is this something I should be worried about?

#2 - Does it have any effect on accuracy?

The reason I ask #2 is that I took my handloads to the range and they all 6 shot horribly. Not one group under 1". I was totaly diqusted. I dont know if i was just having a terrible day or the loads for some reason sucked in my gun even though MANY people claim they are the best loads theyve shot in their AR15's. The only 2 things I can think of are I need to find the right OAL and that the reloads dont feed a easily as the factory stuff.

I've used the SB die on several different brands of bras with the same results. I guess the bushmaster upper chamber just has very tight tolerances? But if I cant shoot reloads that are more accurate than cheap factory stuff with it I dont want it.

And ideas? Its supposed to rain all week so no range time this week it looks like.

frustrated,

Rodney