I built my own 308 AR out of a conglomeration of parts. Let me be the first to say, I know it’s not the same as small frame ARs. I am using a Wilson Arms barrel and a tool craft bcg, JP rail and palmetto upper/lower. I was trying to build it on the cheap and I’m paying for it in down time. My first outing I tried to chamber my first round it would not go fully into battery.

I’ve read several threads on large frame failures and decided the next step (probably should have been the first step while putting everything together) was to check headspace. I pulled the barrel and stripped the bolt.

Go gauge in the barrel.

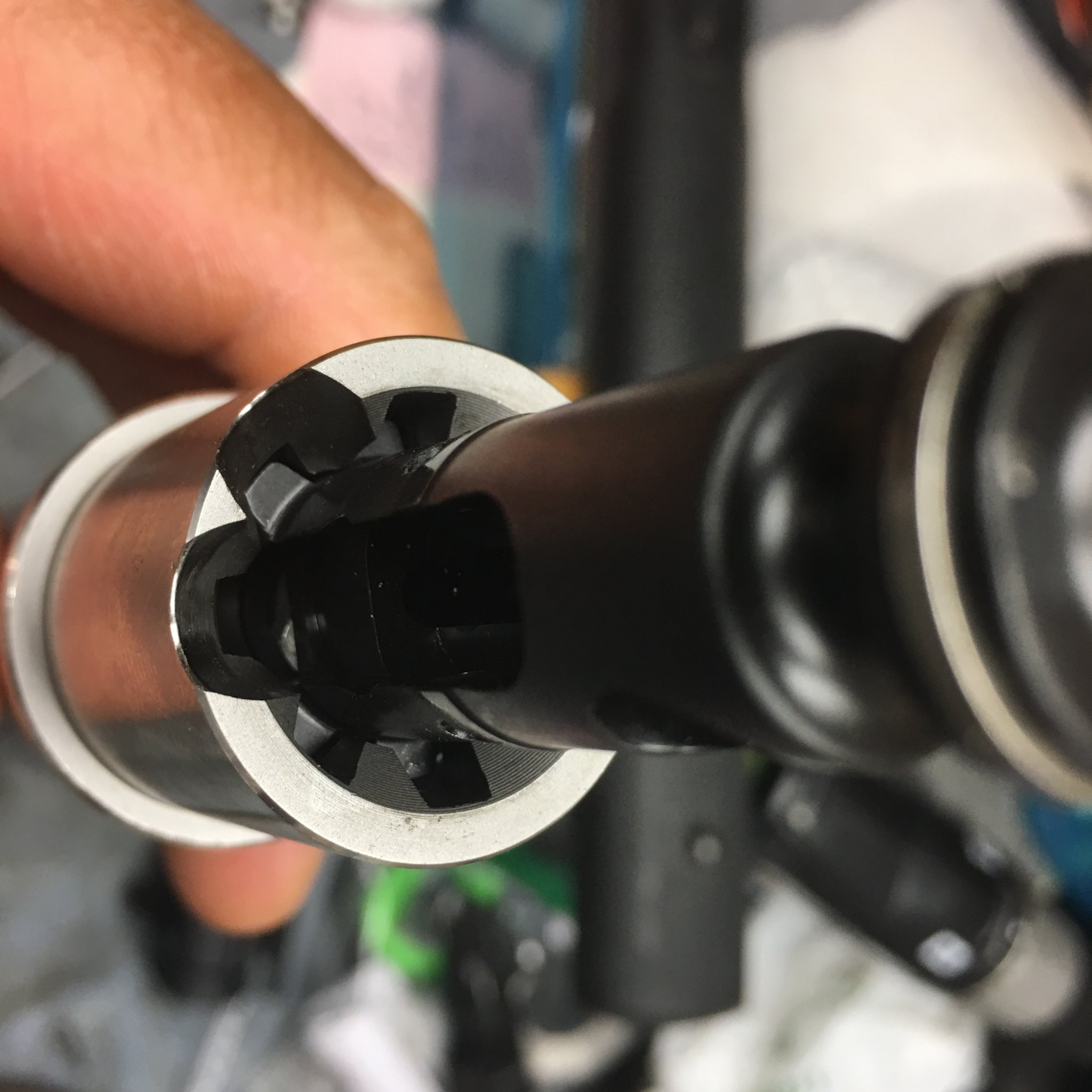

Go gauge and stripped bolt.

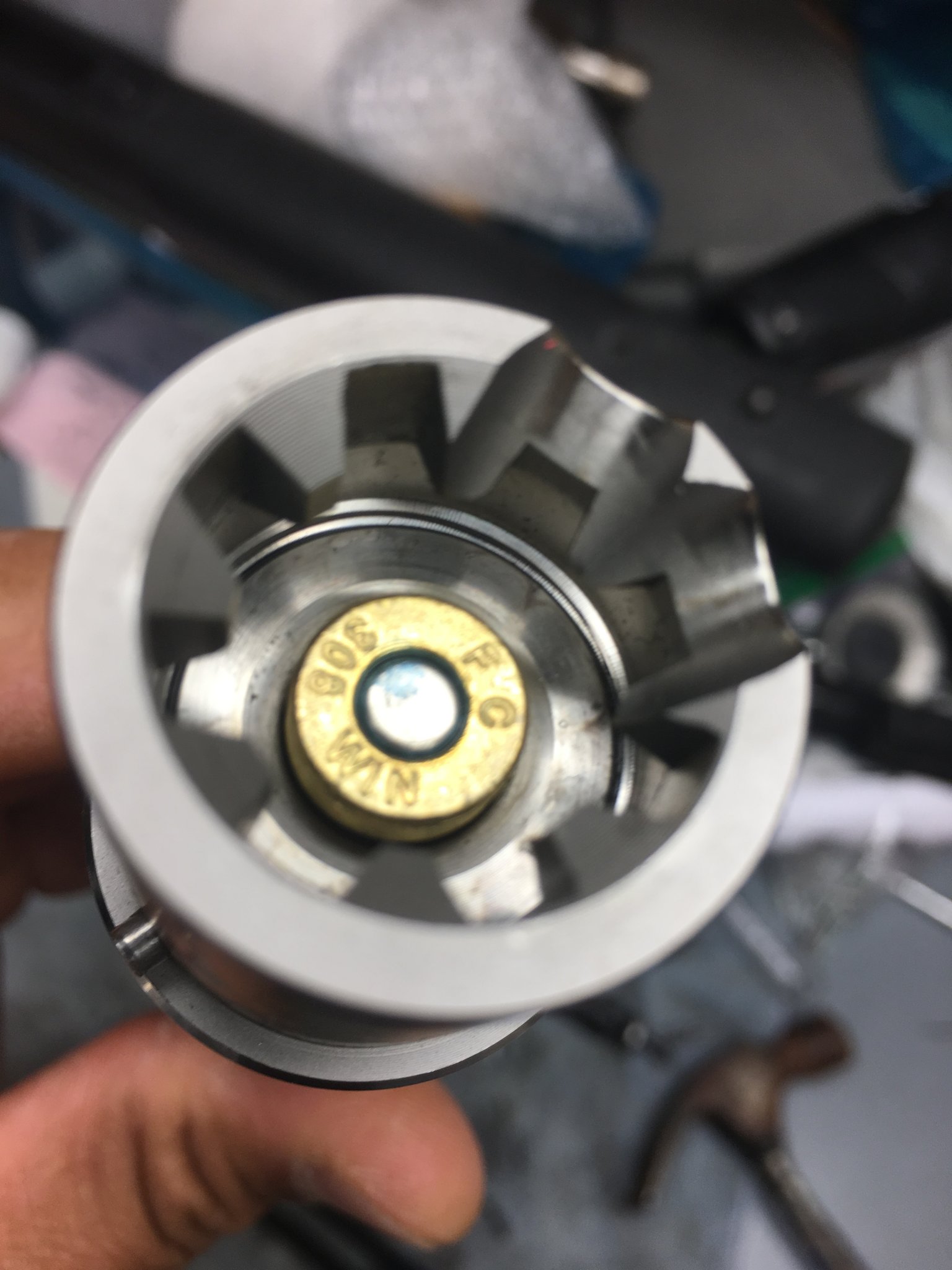

No go gauge

No go gauge with bolt.

168 gr Sierra matchking

I am at a lose. I know on bolt guns that I shouldn’t be able to close the bolt on no go and be able to close on go. I can see a physical difference without the bolt in place between the two gauges but once the bolt it in the barrel they look the same. What am I missing here?

I’ve read several threads on large frame failures and decided the next step (probably should have been the first step while putting everything together) was to check headspace. I pulled the barrel and stripped the bolt.

Go gauge in the barrel.

Go gauge and stripped bolt.

No go gauge

No go gauge with bolt.

168 gr Sierra matchking

I am at a lose. I know on bolt guns that I shouldn’t be able to close the bolt on no go and be able to close on go. I can see a physical difference without the bolt in place between the two gauges but once the bolt it in the barrel they look the same. What am I missing here?