You guys are really stuck in the mud.

There are way better tools out there and because you have not seen them they get no love from you.

Bondhus are a bare bones minimum for quality.

These are an order of magnitude better.

www.wihatools.com

www.wihatools.com

www.knipex.com

www.knipex.com

And it goes on and on....there are tools, then there are quality tools.

There are way better tools out there and because you have not seen them they get no love from you.

Bondhus are a bare bones minimum for quality.

These are an order of magnitude better.

8 Piece SoftGrip Dual Drive Metric T-Handle Set

Wiha Soft Grip Dual Drive Ball End Hex T-Handle Metric Chrome Finish 8 Piece Set in Metal Stand

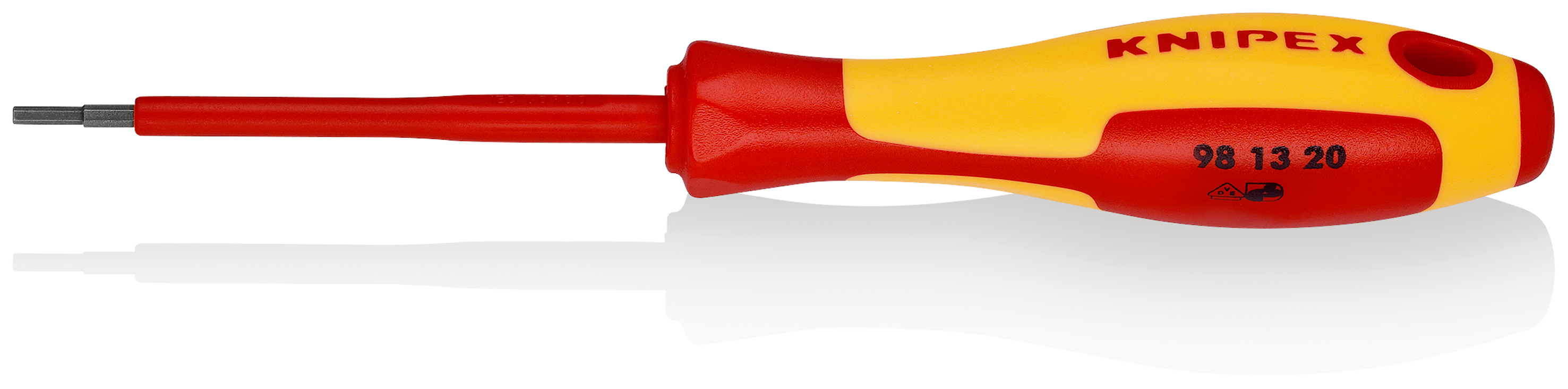

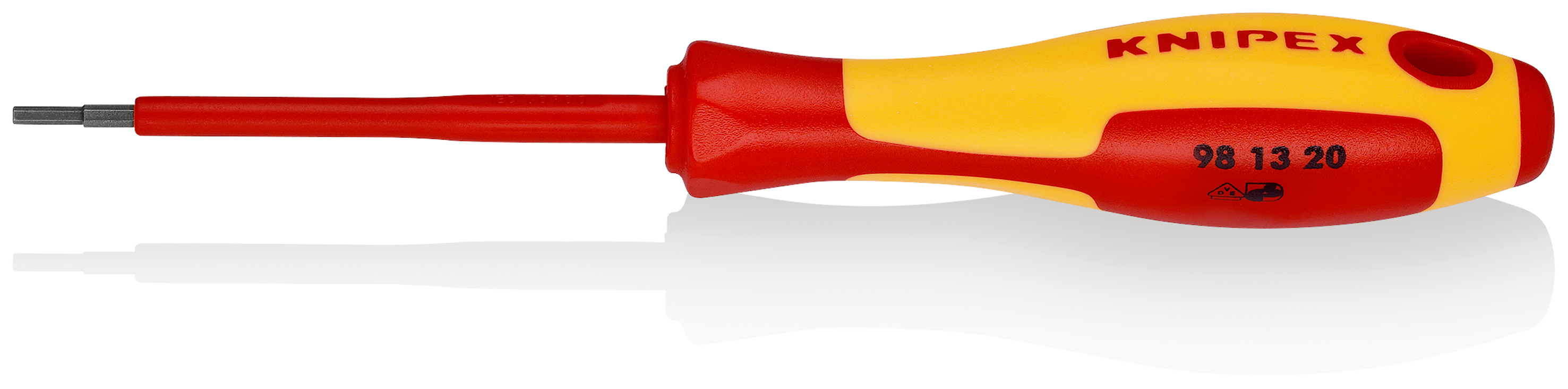

Screwdrivers for hexagon socket screws

Ergonomisch optimierter 2-Komponenten-Griff für ermüdungsarme und handschonende Kraftübertragung, Rollhemmende Griffform, Chrom-Vanadin-Molybdän-Stahl

And it goes on and on....there are tools, then there are quality tools.