From Midway’s site:

- Machined From Solid 6061-T6 Aluminum

If it says “AR-Stoner”, I avoid the parts as a rule based on past experience and the experience of many others. AR-Stoner is often re-branded low price point excrement marketing by Midway as their house brand. I love Midway and have ordered from them for decades, but I must dispassionately call out trash parts when I see them.

You basically installed a custom headers onto a refurbished junkyard engine block off a Yugo.

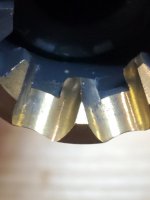

One thing I do to barrel extensions, if they haven’t been tumble-polished by the barrel-maker, is de-edge, blend, and polish the feed ramps. Only do this if you are moderately mechanically-inclined. Especially if you reload and want lots of life out of valuable brass, you’ll want the sharp edges removed from the barrel extension, bolt, and magazines if present. You want smooth transition for your brass out of the fee lips, up the ramp, and into the chamber.

I also bed the barrel into the upper before torquing the barrel nut, letting the sealant set and dry before applying torque, with the nut holding the flange securely to the upper receiver face. This ensures the extension and barrel are properly clocked and can’t be turned out of TDC when torque is applied.

I do this after trouble-shooting the bolt articulation into the extension in positions of function. The way I assemble an upper today feels entirely different than when I just bashed parts together 20-30 years ago for M4orgeries.