Howdy everyone. I had a case head separation today in my 300 win mag and it's got me stumped. Does anyone know what's up with these indentations on the shoulder? The load used has alway been fine and the shot that resulted in the separation felt, sounded, and hit like normal.

- Thread starter Bob Ross

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Three. And, for better or worse, I annealed it.How many firing on that brass?

Can you provide more details? Load data, rifle type, etc.

Sure thing. 212gr Eld-x, 64.8 gr H4350, fed. lmr primer, Federal brass, 3.600" OAL and that gets me 2830 ft/s with no signs of pressure. Rifle is a Christensen Ridgeline and it was 84 degrees at the time.Can you provide more details? Load data, rifle type, etc.

Case head separation on belted magnums right above the belt is a known stretching point. I would attribute that to oversizing the brass, not knowing any details about your reloading regimen. What is perplexing is the dents on the shoulder. Was the brass stuck in the chamber after the head separation? I would have thought it was shot in a semi auto and hit on something while extracting.

Just off the top of my head.

Don't try to reload that case again ?

I can tell by the discoloration of the neck, you over cooked that sucker.

It blew the case into the chamber wicked hard and the sides of the case sucked in when it tried to enter the throat/rifling.

Don't try to reload that case again ?

I can tell by the discoloration of the neck, you over cooked that sucker.

It blew the case into the chamber wicked hard and the sides of the case sucked in when it tried to enter the throat/rifling.

The brass was stuck. The bolt lifted like normal, but I had to whomp the handle, at which point the head separated. I used a bronze brush to get the rest of the case out, and it didn't take too much effort.

The barrel is fine, but the dents are freaking me out. I've never seen brass do that and I can't figure out what would cause it aside from the neck not sealing. With that said, there wasn't any fouling on the neck.

The barrel is fine, but the dents are freaking me out. I've never seen brass do that and I can't figure out what would cause it aside from the neck not sealing. With that said, there wasn't any fouling on the neck.

Please explain your first statement... I can follow the logic on the second statement but you better get with Lapua, Peterson, ADG and others as their brass looks similar.I can tell by the discoloration of the neck, you over cooked that sucker.

It blew the case into the chamber wicked hard and the sides of the case sucked in when it tried to enter the throat/rifling.

That definitely makes sense. It was my first attempt at annealing nickle brass. I'm leaning more toward, it's not worth it, now.Just off the top of my head.

Don't try to reload that case again ?

I can tell by the discoloration of the neck, you over cooked that sucker.

It blew the case into the chamber wicked hard and the sides of the case sucked in when it tried to enter the throat/rifling.

Dents are caused when the case ruptured and internal pressure dropped. Hot gasses flowed around the neck causing the shoulder to collapse.

Dents are caused when the case ruptured and internal pressure dropped. Hot gasses flowed around the neck causing the shoulder to collapse.

This.

Annealing looks to have had nothing to do with the separation. You need to check all your cases for thin spots in front of the belt. You should also confirm your shoulder bump of your sizing die, it’s probably excessive.

If that brass is nickel coated, you’re working against yourself reloading it at all. Toss it or sell it.That definitely makes sense. It was my first attempt at annealing nickle brass. I'm leaning more toward, it's not worth it, now.

Alright.

See the blue circle ???

See the secondary line there ?

That is where the case shoved forward after it broke, should be easy to understand with the enhancement, right ?

You can also see it at the neck to shoulder junction, a clear secondary line.

See the red circle, notice how blackish and burnt it looks.

That's from overheating when annealing it, it literally burnt the metal.

See the blue circle ???

See the secondary line there ?

That is where the case shoved forward after it broke, should be easy to understand with the enhancement, right ?

You can also see it at the neck to shoulder junction, a clear secondary line.

See the red circle, notice how blackish and burnt it looks.

That's from overheating when annealing it, it literally burnt the metal.

My take, FWIW.

You had a partial case head separation just above the belt.

When the case cracked some gas vented out of the case and increased pressure in the chamber between the case and the chamber wall. Its a timing thing with internal case pressure decreasing and the (very small amount) of high pressure gas in the chamber looking for the path of least resistance. That forced the brass “in” by the neck and caused the dents. It does not always happen, but I have seen it just like this before on partial case head separations.

When the bolt lifted “normal”, you actually probably spun the bolt on the case head (interested to see if light swipe marks) and when you whomped the bolt handle the crack let go and the case came all the way apart.

Annealing (good or bad) did not cause this. Thin brass above the belt did—most likely from your sizing/headspace process.

And finally, agree the rest of the batch is suspect.

My 0.02.

ZY

You had a partial case head separation just above the belt.

When the case cracked some gas vented out of the case and increased pressure in the chamber between the case and the chamber wall. Its a timing thing with internal case pressure decreasing and the (very small amount) of high pressure gas in the chamber looking for the path of least resistance. That forced the brass “in” by the neck and caused the dents. It does not always happen, but I have seen it just like this before on partial case head separations.

When the bolt lifted “normal”, you actually probably spun the bolt on the case head (interested to see if light swipe marks) and when you whomped the bolt handle the crack let go and the case came all the way apart.

Annealing (good or bad) did not cause this. Thin brass above the belt did—most likely from your sizing/headspace process.

And finally, agree the rest of the batch is suspect.

My 0.02.

ZY

Last edited:

Whats wrong wth loading nickel coated brass?If that brass is nickel coated, you’re working against yourself reloading it at all. Toss it or sell it.

Just internet myths , not a thing wrong with it . People anneal and load it everyday . With success .Whats wrong wth loading nickel coated brass?

Large quantities of people doing things doesn’t make it wise or right.Just internet myths , not a thing wrong with it . People anneal and load it everyday . With success .

(There’s a hint in there for your satanic political opinions, too)

Whats wrong wth loading nickel coated brass?

The nickel is harder than the die steel. With use the nickel will flake off and will tear up your dies. Use a borescope on dies that you’ve run nickel through for any length of time and check for yourself. I did, that’s why I don’t run it anymore.

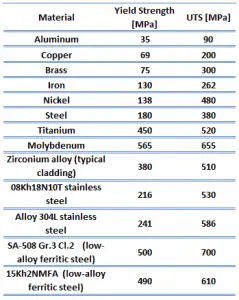

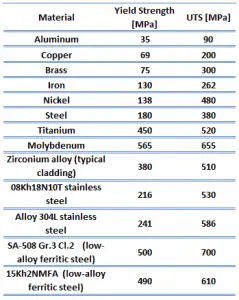

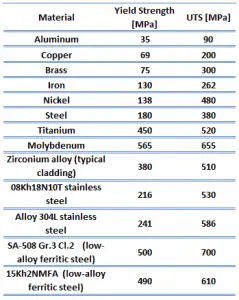

Not all nickel alloys are harder than steel. It would seem smart to use something soft, kind of like how they don't use chisel steel for steel cased ammo.

continentalsteel.com

continentalsteel.com

For example constantan {55% copper 45% nickel} is right between soft brass and copper in hardness. if you read through this one.

What alloy are nickel cases coated with? What did the dies look like before running nickel cases? What was the problem that made you scope the dies?

Understanding Nickel Alloys - Monel® and Hastelloy®

Nickel and its many alloys provide a wide array of benefits to projects spanning multiple industries. In this post we detail the benefits of these metals

For example constantan {55% copper 45% nickel} is right between soft brass and copper in hardness. if you read through this one.

Properties of Nickel Alloys - Strength - Hardness - Thermal Properties | nuclear-power.com

Nickel alloys have excellent resistance to thermal creep deformation and retain their stiffness, strength, toughness, and dimensional stability at temperatures much higher than the other aerospace structural materials.

www.nuclear-power.com

What alloy are nickel cases coated with? What did the dies look like before running nickel cases? What was the problem that made you scope the dies?

Hmmm??? If the nickel is harder than dies steel, it sure turned easy enough when I turned the neck on some .308 nickel coated brass. This brass has been fired 5 times and reloaded 4 times and no problems with flaking off . . . yet.Large quantities of people doing things doesn’t make it wise or right.

(There’s a hint in there for your satanic political opinions, too)

The nickel is harder than the die steel. With use the nickel will flake off and will tear up your dies. Use a borescope on dies that you’ve run nickel through for any length of time and check for yourself. I did, that’s why I don’t run it anymore.

Not all nickel alloys are harder than steel. It would seem smart to use something soft, kind of like how they don't use chisel steel for steel cased ammo.

Understanding Nickel Alloys - Monel® and Hastelloy®

Nickel and its many alloys provide a wide array of benefits to projects spanning multiple industries. In this post we detail the benefits of these metalscontinentalsteel.com

For example constantan {55% copper 45% nickel} is right between soft brass and copper in hardness. if you read through this one.

Properties of Nickel Alloys - Strength - Hardness - Thermal Properties | nuclear-power.com

Nickel alloys have excellent resistance to thermal creep deformation and retain their stiffness, strength, toughness, and dimensional stability at temperatures much higher than the other aerospace structural materials.www.nuclear-power.com

What alloy are nickel cases coated with? What did the dies look like before running nickel cases? What was the problem that made you scope the dies?

I have no idea what alloy it is. The dies were brand new (.243) RCBS. I noticed the nickel was flaking off and mentioned it to a gunsmith at the time (25 years ago). He told me the that it could scratch my dies, and I said that I had noticed scratches, and he had me bring the dies in. We checked them with his borescope. The nickel (almost all that I had used at the time) had definitely scratched the inside of my die, more scratched than I thought it’d be. Never used it again.

You turned your necks with your dies? The flaking I have experienced was generally around the neck, so…Hmmm??? If the nickel is harder than dies steel, it sure turned easy enough when I turned the neck on some .308 nickel coated brass. This brass has been fired 5 times and reloaded 4 times and no problems with flaking off . . . yet.

View attachment 7945716

Maybe the turning of the necks has solved that problem???You turned your necks with your dies? The flaking I have experienced was generally around the neck, so…

I’ve reloaded several case manufacturers with Hornady being the only one that has given me the case head separation. Is it just the luck of the draw? I full-size my 300 win brass…

Attachments

In my experience hornady and federal brass tend to be softer that say Lapua. Softer thicker brass can flow easier and thin where the separation occurred. My theory anywaysI’ve reloaded several case manufacturers with Hornady being the only one that has given me the case head separation. Is it just the luck of the draw? I full-size my 300 win brass…

Oversizing FL as noted above in original post will accelerate this. Every time you trim your brass it’s brass flowing forward on the case. Brass flows to the front, you trim it off, brass gets thin in back

Absolutely a signAnd because of this if you notice your brass is growing past trim length really fast, it might be a clue you are oversizing.