I've got a brand new rifle that I've been working up a load for. I am trying to get a good ballpark load to shoot about 100-150 rounds through before I set my sights on my final COAL/jump. Even just in the first 60 rounds my bullet has gone from touching the lands at 2.227 to now 2.232. What I'm experiencing right now is some pretty high ES numbers, and I'm trying to get them down. So I'll run you through everything I've got and how I'm loading.. any variables I can think of and let me know what you think, if you don't mind.

Rifle:

.308 in a Broughton 22" comp contour 1:10

Load:

Winchester brass (unfired) and annealed

All trimmed to same length

Headspace bumped back .002 from fired case

Fed 210 primers

.003 neck tension

Nosler 175 RDF (factory seconds/blems)

44.8gr Varget

Seated to 2.207"

Chrono: Labradar

I am fixated on these 175 RDFs and the huge variation in bullet weight I get on these blems. Each box of 100 has a variation of about 1.2 gr from the lightest to heaviest bullet. They very well may NOT be the problem, but that's another reason why I'm here - hopefully we can figure that out. I am using Redding Type S sizing dies, Forster competition seating die, and throwing charges from the Chargemaster at .1 gr under and then trickling up the last grain and stopping the second it tips up to 44.8gr. This is another point that could cause my issue which I'm trying to remedy. I ordered a GemPro 250 and I'll be testing next week to see if I can get more accurate throws. I also plan on pulling a few bullets from what I have loaded now and weighing those charges on the GemPro when it gets here to see how consistent they were.

My seating depth is +/- .002 from 2.207 which put my jump at .020 from my initial measurement. Now it's a bit more - but I've heard these RDFs really like to jump. Is that something that I should change? I think my .002 variation is from the LNL press I'm using. I know a lot of guys hate on the LNL and it's kind of frowned on to load precision ammo on a progressive, but I don't have this ES issue with other precision rifle loads where I was using a 178 AMAX in my other .308. That rifle has some great ES numbers.

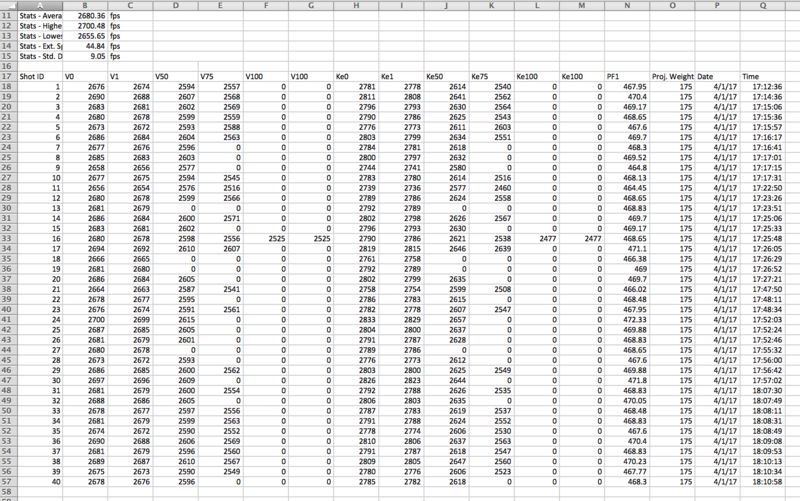

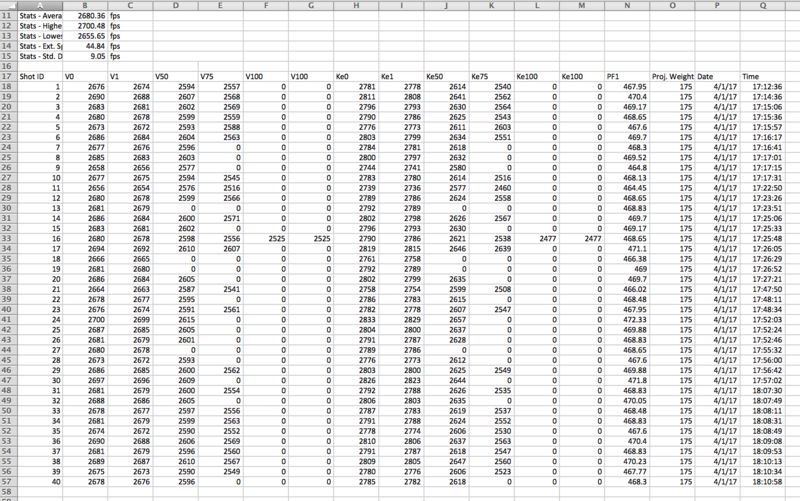

So I've attached my report from my Labradar for you to take a look at. Am I crazy to blame these blem RDFs? It annoys the hell outta me that those vary so much and my 175 VLDs are all within .1gr of each other.

Rifle:

.308 in a Broughton 22" comp contour 1:10

Load:

Winchester brass (unfired) and annealed

All trimmed to same length

Headspace bumped back .002 from fired case

Fed 210 primers

.003 neck tension

Nosler 175 RDF (factory seconds/blems)

44.8gr Varget

Seated to 2.207"

Chrono: Labradar

I am fixated on these 175 RDFs and the huge variation in bullet weight I get on these blems. Each box of 100 has a variation of about 1.2 gr from the lightest to heaviest bullet. They very well may NOT be the problem, but that's another reason why I'm here - hopefully we can figure that out. I am using Redding Type S sizing dies, Forster competition seating die, and throwing charges from the Chargemaster at .1 gr under and then trickling up the last grain and stopping the second it tips up to 44.8gr. This is another point that could cause my issue which I'm trying to remedy. I ordered a GemPro 250 and I'll be testing next week to see if I can get more accurate throws. I also plan on pulling a few bullets from what I have loaded now and weighing those charges on the GemPro when it gets here to see how consistent they were.

My seating depth is +/- .002 from 2.207 which put my jump at .020 from my initial measurement. Now it's a bit more - but I've heard these RDFs really like to jump. Is that something that I should change? I think my .002 variation is from the LNL press I'm using. I know a lot of guys hate on the LNL and it's kind of frowned on to load precision ammo on a progressive, but I don't have this ES issue with other precision rifle loads where I was using a 178 AMAX in my other .308. That rifle has some great ES numbers.

So I've attached my report from my Labradar for you to take a look at. Am I crazy to blame these blem RDFs? It annoys the hell outta me that those vary so much and my 175 VLDs are all within .1gr of each other.

Last edited: