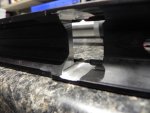

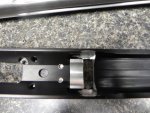

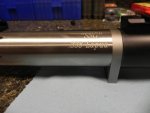

With the generosity of Justin from KRG and a case of Coors Light to trade my buddy for use of his mill, I've got a functioning Gen 4 Whiskey 3 chassis wrapped around my SSG/Rock/Stiller TAC338 barreled action. As some of you may know, the TAC338 action is almost a half inch longer than a standard Remington LA. The bolt pattern is the same, just the action is larger in diameter and longer in the tenon. While this is good for strength when dealing with the 338LM, the availability of chassis and stock systems are limited. My initial plan for this build was this Stiller action bolted into an AX AICS chassis. After jumping on the group buy last year, I guess I overlooked the action dimensions. Everyone I talked to said it was a definite no-go with the AX due to the forend. There was one Hide member who had a shop make a Legacy AICS work with the bigger action. Russ from Stiller was helpful but no one really knew what chassis would work without grinding on a $1000-1400 guinea pig. The XLR didn't have the look I was going after and a McMillan A5 would have been a big departure from all my other chassis guns.

Enter Justin from KRG aka Massoud. I simply responded to his thread showing off his new Gen 4 Whiskey 3 chassis. He just started offering a Long Action Rem 700 footprint version and I asked if he had any plans for the Stiller. Since I've been hearing NO for the last year, my expectations were low. Justin was open to the possibility. I offered to just send him my barreled action that's been collecting dust, but without an FFL, he couldn't accept it from me. Within a week a package showed up at my door from KRG. Justin sent me a chassis minus the rear stock portion to give it a go. I've been a mechanic most of my life and run heavy equipment for a paycheck, but I'm no machinist. I've fabricated my fair share of random things with a Dremel, but I really wanted something respectable. I bought off my buddy who has a mill and here are the results from some rank amateurs pretending to be gunsmiths!

Enter Justin from KRG aka Massoud. I simply responded to his thread showing off his new Gen 4 Whiskey 3 chassis. He just started offering a Long Action Rem 700 footprint version and I asked if he had any plans for the Stiller. Since I've been hearing NO for the last year, my expectations were low. Justin was open to the possibility. I offered to just send him my barreled action that's been collecting dust, but without an FFL, he couldn't accept it from me. Within a week a package showed up at my door from KRG. Justin sent me a chassis minus the rear stock portion to give it a go. I've been a mechanic most of my life and run heavy equipment for a paycheck, but I'm no machinist. I've fabricated my fair share of random things with a Dremel, but I really wanted something respectable. I bought off my buddy who has a mill and here are the results from some rank amateurs pretending to be gunsmiths!