Hi,

It is very nice to see older "concepts" merge with modern technology/understandings to bring us improvements

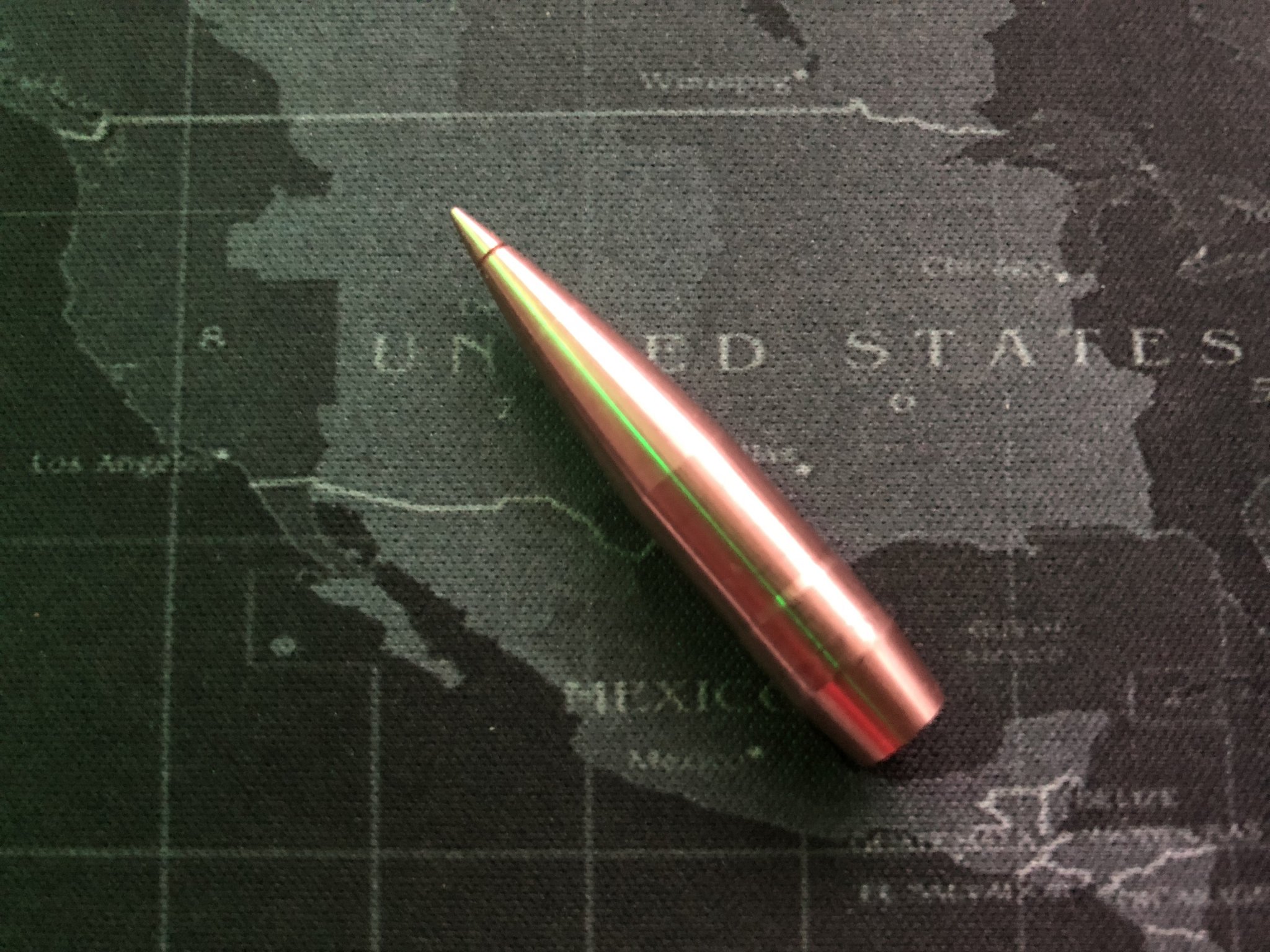

Cheytac & Associates had the "concept" of lighter weight for caliber projectile (305gr Dominator) to achieve higher MV but did not pair it with a fast enough twist rate to achieve hyper stabilization.

Lutz Moeller recommended a 6.5 twist rate for his LM105 .338 projectiles but did not have the MV needed to achieve hyper stabilization because the projectiles were heavy for caliber.

Gerard at GS saying that his projectiles would handle a stability factor of 3+.

Klaus had the "concept" of lighter weight for caliber paired with crazy high MV (Mach IV 375/BMG wildcat) but did not pair it with a fast enough twist rate to achieve hyper stabilization.

Jim...do you know what calibers you will be releasing the MkII version in?

Edited To Add:

Jim, I understand you are having a barrel spun up for these to provide field data but what is PRODAS telling you in regards to the bleeding off of the BC? As you mentioned...that is great BC number at Mach 2.5! Is PRODAS showing a steady bleed off curve or is there a "minimum" flight velocity you are recommending?

This is where the 305gr Dominator .408 projectile sucks at....it sheds BC and Velocity drastically.

Sincerely,

Theis