Uh, when did SWR start rosette welding the Omega 300? One I ordered came in yesterday and it is rosette welded like an AAC. FUGLY.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Having trouble using the site?

Contact support

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re: WTF SWR Omega 300

are you sure its not a sex toy that you forgot you ordered ?

..................sorry couldn't help myself Andrew

are you sure its not a sex toy that you forgot you ordered ?

..................sorry couldn't help myself Andrew

Re: WTF SWR Omega 300

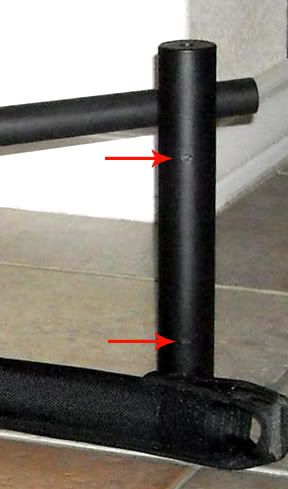

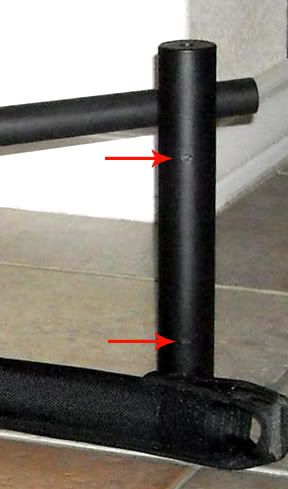

I believe he means something like these where they weld the the tube to the core I'm guessing? My Omega 300 in the photo below has like 4 or 6 I don't really know never counted them but as long as the can is quiet and repeatable I'm happy

I believe he means something like these where they weld the the tube to the core I'm guessing? My Omega 300 in the photo below has like 4 or 6 I don't really know never counted them but as long as the can is quiet and repeatable I'm happy

Re: WTF SWR Omega 300

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: BOLTRIPPER</div><div class="ubbcode-body">are you sure its not a sex toy that you forgot you ordered ?

..................sorry couldn't help myself Andrew </div></div>

No, this one is only 11 inches. Mine are usually 16 plus.

A rosette weld is when you drill a hole and then fill it in with a weld. Its a cost cutting thing.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: BOLTRIPPER</div><div class="ubbcode-body">are you sure its not a sex toy that you forgot you ordered ?

..................sorry couldn't help myself Andrew </div></div>

No, this one is only 11 inches. Mine are usually 16 plus.

A rosette weld is when you drill a hole and then fill it in with a weld. Its a cost cutting thing.

Re: WTF SWR Omega 300

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: microsuck</div><div class="ubbcode-body">

A rosette weld is when you drill a hole and then fill it in with a weld. <span style="color: #FF0000">Its a cost cutting thing</span>. </div></div>

How is making a plug weld a cust cutting thing? And what AAC can has plug welds? As far as I know all AAC cans have fully welded cores.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: microsuck</div><div class="ubbcode-body">

A rosette weld is when you drill a hole and then fill it in with a weld. <span style="color: #FF0000">Its a cost cutting thing</span>. </div></div>

How is making a plug weld a cust cutting thing? And what AAC can has plug welds? As far as I know all AAC cans have fully welded cores.

Re: WTF SWR Omega 300

Actually most times robotic fusion welding (like AAC uses) Is cheaper to implement than methodical manual fill welding.

There is skeptisism that a fusion weld which fuses the two metals together and uses no filling material might not be as strong as a Fill weld as seen on KAC suppressors.

I belive that there are some cans that need the strength and others that dont. I personally (and this is only my opinion) feel that fusion welding is not as durable as filler welding whether it be robotic wire, manual, ect...

Actually most times robotic fusion welding (like AAC uses) Is cheaper to implement than methodical manual fill welding.

There is skeptisism that a fusion weld which fuses the two metals together and uses no filling material might not be as strong as a Fill weld as seen on KAC suppressors.

I belive that there are some cans that need the strength and others that dont. I personally (and this is only my opinion) feel that fusion welding is not as durable as filler welding whether it be robotic wire, manual, ect...

Re: WTF SWR Omega 300

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Outsydlooknin75</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: microsuck</div><div class="ubbcode-body">

A rosette weld is when you drill a hole and then fill it in with a weld. <span style="color: #FF0000">Its a cost cutting thing</span>. </div></div>

How is making a plug weld a cust cutting thing? And what AAC can has plug welds? As far as I know all AAC cans have fully welded cores. </div></div>

My M4-1000 is rosette welded. My beef is that its ugly. Not that its cheaper to make.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Outsydlooknin75</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: microsuck</div><div class="ubbcode-body">

A rosette weld is when you drill a hole and then fill it in with a weld. <span style="color: #FF0000">Its a cost cutting thing</span>. </div></div>

How is making a plug weld a cust cutting thing? And what AAC can has plug welds? As far as I know all AAC cans have fully welded cores. </div></div>

My M4-1000 is rosette welded. My beef is that its ugly. Not that its cheaper to make.

Re: WTF SWR Omega 300

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 11B-B4</div><div class="ubbcode-body">Actually most times robotic fusion welding (like AAC uses) Is cheaper to implement than methodical manual fill welding.

There is skeptisism that a fusion weld which fuses the two metals together and uses no filling material might not be as strong as a Fill weld as seen on KAC suppressors.

I belive that there are some cans that need the strength and others that dont. I personally (and this is only my opinion) feel that fusion welding is not as durable as filler welding whether it be robotic wire, manual, ect... </div></div>

Well YEAH of course doing something with a robot is going to be cheaper than doing something manually. For fucks sake, What is cheaper to buy the machine to do a weld that is the same every time or to pay someone to manually do something that cant be duplicated exactly the same from piece to piece?

Just becasue something is welded robotically doesnt mean that it is weaker.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 11B-B4</div><div class="ubbcode-body">Actually most times robotic fusion welding (like AAC uses) Is cheaper to implement than methodical manual fill welding.

There is skeptisism that a fusion weld which fuses the two metals together and uses no filling material might not be as strong as a Fill weld as seen on KAC suppressors.

I belive that there are some cans that need the strength and others that dont. I personally (and this is only my opinion) feel that fusion welding is not as durable as filler welding whether it be robotic wire, manual, ect... </div></div>

Well YEAH of course doing something with a robot is going to be cheaper than doing something manually. For fucks sake, What is cheaper to buy the machine to do a weld that is the same every time or to pay someone to manually do something that cant be duplicated exactly the same from piece to piece?

Just becasue something is welded robotically doesnt mean that it is weaker.

Re: WTF SWR Omega 300

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Outsydlooknin75</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 11B-B4</div><div class="ubbcode-body">Actually most times robotic fusion welding (like AAC uses) Is cheaper to implement than methodical manual fill welding.

There is skeptisism that a fusion weld which fuses the two metals together and uses no filling material might not be as strong as a Fill weld as seen on KAC suppressors.

I belive that there are some cans that need the strength and others that dont. I personally (and this is only my opinion) feel that fusion welding is not as durable as filler welding whether it be robotic wire, manual, ect... </div></div>

Well YEAH of course doing something with a robot is going to be cheaper than doing something manually. For fucks sake, What is cheaper to buy the machine to do a weld that is the same every time or to pay someone to manually do something that cant be duplicated exactly the same from piece to piece?

Just becasue something is welded robotically doesnt mean that it is weaker. </div></div>

It depends on whether the robot is a wire feed robot or a tig robot. The wire feed method will be stronger as metal isn't drawn from the two parts but is instead added. Plug welding strengthens spacers and locks up components so that they don't move over time and many firing cycles so I wouldn't look at a plug weld and say gee that's crap, but at the same time there are probably stronger ways of doing things that we are working with currently. Things I'm sure some people will look at and not like aesthetically, but that may be better for durability and strength.

I think KAC uses some form of TIG without filler metal for plug welds and filler rod for the circumferential welds, as well as for the perforated girdle welds on the M4QD.

Surefire uses filler metal for all it's welds.

AAC I believe uses robotic TIG without filler metal for all or at least nearly all of it's welding.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Outsydlooknin75</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 11B-B4</div><div class="ubbcode-body">Actually most times robotic fusion welding (like AAC uses) Is cheaper to implement than methodical manual fill welding.

There is skeptisism that a fusion weld which fuses the two metals together and uses no filling material might not be as strong as a Fill weld as seen on KAC suppressors.

I belive that there are some cans that need the strength and others that dont. I personally (and this is only my opinion) feel that fusion welding is not as durable as filler welding whether it be robotic wire, manual, ect... </div></div>

Well YEAH of course doing something with a robot is going to be cheaper than doing something manually. For fucks sake, What is cheaper to buy the machine to do a weld that is the same every time or to pay someone to manually do something that cant be duplicated exactly the same from piece to piece?

Just becasue something is welded robotically doesnt mean that it is weaker. </div></div>

It depends on whether the robot is a wire feed robot or a tig robot. The wire feed method will be stronger as metal isn't drawn from the two parts but is instead added. Plug welding strengthens spacers and locks up components so that they don't move over time and many firing cycles so I wouldn't look at a plug weld and say gee that's crap, but at the same time there are probably stronger ways of doing things that we are working with currently. Things I'm sure some people will look at and not like aesthetically, but that may be better for durability and strength.

I think KAC uses some form of TIG without filler metal for plug welds and filler rod for the circumferential welds, as well as for the perforated girdle welds on the M4QD.

Surefire uses filler metal for all it's welds.

AAC I believe uses robotic TIG without filler metal for all or at least nearly all of it's welding.

Re: WTF SWR Omega 300

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: microsuck</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Outsydlooknin75</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: microsuck</div><div class="ubbcode-body">

A rosette weld is when you drill a hole and then fill it in with a weld. <span style="color: #FF0000">Its a cost cutting thing</span>. </div></div>

How is making a plug weld a cust cutting thing? And what AAC can has plug welds? As far as I know all AAC cans have fully welded cores. </div></div>

My M4-1000 is rosette welded. My beef is that its ugly. Not that its cheaper to make. </div></div>

What model is your 1000? I just wnet and looked at my mod08 and its not plug welded anywhere that I can see.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: microsuck</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Outsydlooknin75</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: microsuck</div><div class="ubbcode-body">

A rosette weld is when you drill a hole and then fill it in with a weld. <span style="color: #FF0000">Its a cost cutting thing</span>. </div></div>

How is making a plug weld a cust cutting thing? And what AAC can has plug welds? As far as I know all AAC cans have fully welded cores. </div></div>

My M4-1000 is rosette welded. My beef is that its ugly. Not that its cheaper to make. </div></div>

What model is your 1000? I just wnet and looked at my mod08 and its not plug welded anywhere that I can see.

Re: WTF SWR Omega 300

Who cares what it looks like? It does its job. I have one that is welded like it and guess what? You never see it because it stays under its TAB mirage cover!

Who cares what it looks like? It does its job. I have one that is welded like it and guess what? You never see it because it stays under its TAB mirage cover!

Re: WTF SWR Omega 300

My M4-1000 is an 07, yes, it is rosette welded.

I have customers that care about looks, so if I am selling them cans that I think look like this....

And then they show up looking like this.....

Its bad business. How would you feel if you were the customer.

My M4-1000 is an 07, yes, it is rosette welded.

I have customers that care about looks, so if I am selling them cans that I think look like this....

And then they show up looking like this.....

Its bad business. How would you feel if you were the customer.

Re: WTF SWR Omega 300

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: microsuck</div><div class="ubbcode-body">My M4-1000 is an 07, yes, it is rosette welded.

I have customers that care about looks, so if I am selling them cans that I think look like this....

And then they show up looking like this.....

Its bad business. How would you feel if you were the customer. </div></div>

That would suck, and AAC doesn't Weld like that anymore..

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: microsuck</div><div class="ubbcode-body">My M4-1000 is an 07, yes, it is rosette welded.

I have customers that care about looks, so if I am selling them cans that I think look like this....

And then they show up looking like this.....

Its bad business. How would you feel if you were the customer. </div></div>

That would suck, and AAC doesn't Weld like that anymore..

Re: WTF SWR Omega 300

At least with the new radiused edges it will be easier for them to get the TAB cover on.

At least with the new radiused edges it will be easier for them to get the TAB cover on.

Re: WTF SWR Omega 300

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: microsuck</div><div class="ubbcode-body">My M4-1000 is an 07, yes, it is rosette welded.

I have customers that care about looks, so if I am selling them cans that I think look like this....

And then they show up looking like this.....

Its bad business. How would you feel if you were the customer. </div></div>

WAIT a minute. So the customer orders a SWR and ends up with an AAC, FUCK yeah Id bitch too. Cause the ATF approved a SWR with a specific serial number, not an AAC with a completely different number.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: microsuck</div><div class="ubbcode-body">My M4-1000 is an 07, yes, it is rosette welded.

I have customers that care about looks, so if I am selling them cans that I think look like this....

And then they show up looking like this.....

Its bad business. How would you feel if you were the customer. </div></div>

WAIT a minute. So the customer orders a SWR and ends up with an AAC, FUCK yeah Id bitch too. Cause the ATF approved a SWR with a specific serial number, not an AAC with a completely different number.

Re: WTF SWR Omega 300

I see your point there. The company should probably update the web photos.

I see your point there. The company should probably update the web photos.

Re: WTF SWR Omega 300

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 427Cobra</div><div class="ubbcode-body">I sure am glad I bought a Shark, oh its quieter too, ah-ha! </div></div>

What is the weight,size, POI shift, mounting attachment, materials, and what does it meter as far as FRP goes on the Shark?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 427Cobra</div><div class="ubbcode-body">I sure am glad I bought a Shark, oh its quieter too, ah-ha! </div></div>

What is the weight,size, POI shift, mounting attachment, materials, and what does it meter as far as FRP goes on the Shark?

Re: WTF SWR Omega 300

Tigershark

Titanium and inconel not weleded

now have modular thread on design.

Poi shift minimul mostly depends on your rifle.

25 oz 1.625 10 inches

Mine metered 135 but sound meters dont prove jack you need to here....them against the competetion!

Shark is the same but 16 oz. 1.5 od 8.5 inches. lengths are a bit longer than now with the thread adapters .250 longer

Tigershark

Titanium and inconel not weleded

now have modular thread on design.

Poi shift minimul mostly depends on your rifle.

25 oz 1.625 10 inches

Mine metered 135 but sound meters dont prove jack you need to here....them against the competetion!

Shark is the same but 16 oz. 1.5 od 8.5 inches. lengths are a bit longer than now with the thread adapters .250 longer

Re: WTF SWR Omega 300

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 737SHARK</div><div class="ubbcode-body">Tigershark

Titanium and inconel not weleded

now have modular thread on design.

Poi shift minimul mostly depends on your rifle.

25 oz 1.625 10 inches

Mine metered 135 but sound meters dont prove jack you need to here....them against the competetion!

Shark is the same but 16 oz. 1.5 od 8.5 inches. lengths are a bit longer than now with the thread adapters .250 longer

</div></div>

I wasnt trying to be a dick by asking those questions.

I was just curious. So many people when they compare suppressors dont compare them properly. Most want to compare apples to oranges. And I agree you have to hear them side by side the meter doesnt tell it all. The tone plays a big factor as welll. I was just curious as to how much louder the first round pop was in comparison. To me that means more than at the end of a five shot string.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 737SHARK</div><div class="ubbcode-body">Tigershark

Titanium and inconel not weleded

now have modular thread on design.

Poi shift minimul mostly depends on your rifle.

25 oz 1.625 10 inches

Mine metered 135 but sound meters dont prove jack you need to here....them against the competetion!

Shark is the same but 16 oz. 1.5 od 8.5 inches. lengths are a bit longer than now with the thread adapters .250 longer

</div></div>

I wasnt trying to be a dick by asking those questions.

I was just curious. So many people when they compare suppressors dont compare them properly. Most want to compare apples to oranges. And I agree you have to hear them side by side the meter doesnt tell it all. The tone plays a big factor as welll. I was just curious as to how much louder the first round pop was in comparison. To me that means more than at the end of a five shot string.

Re: WTF SWR Omega 300

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Outsydlooknin75</div><div class="ubbcode-body">

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Outsydlooknin75</div><div class="ubbcode-body">

microsuck said:And then they show up looking like this.....

Its bad business. How would you feel if you were the customer. </div></div>

Plain and simple, that's got to be a mistake. Contact SWR, send them pictures and if their <span style="text-decoration: underline">name is on that can</span> they will make it right. Period!

I have owned several SWR cans in all different calibers and all were nothing short of outstanding. I have had only one issue and customer service was also outstanding.

Maybe the dealer did it, not the manufacturer? Hmmm???

Re: WTF SWR Omega 300

That's not the SWR in question, it is, I believe, a picture of a first generation AAC can. My SWR Omega 300 had 5 welds like that, all relatively small, all there for some reason that is beyond my knowledge, and all covered up by my TAB cover...a necessity, in my opinion.

That's not the SWR in question, it is, I believe, a picture of a first generation AAC can. My SWR Omega 300 had 5 welds like that, all relatively small, all there for some reason that is beyond my knowledge, and all covered up by my TAB cover...a necessity, in my opinion.

Re: WTF SWR Omega 300

The horribly ugly welds you are asking about were implemented because of the phone calls SWR was getting. You know the ones where some guy calls asking if it will hold up to "insert random name"-short-ultra-win-magnum-X. The answer of "The suppressor in question is not rated for that caliber, nor do we have one of those on hand to test it" doesn't seem to matter to some people. Additional strengthening measures were implemented to keep everyone, to include those experimenters safe. Those ugly welds carry a lot of extra strength. In the end it's about keeping EVERYONE safe, even those who should know better.

SWR is using Mr. Burkes excellent TAB GEAR covers currently. Maybe that's why you haven't seen the recent changes on the new models. Might I also humbly suggest you encourage your customers to look at them as well. The mirage-reduction benefits, especially on a .300 Win Mag after a few rounds are nothing less than spectacular.

I hope this helps. I don't work for SWR. If you want I can get one of those guys to come on over and tell you the same thing.

The horribly ugly welds you are asking about were implemented because of the phone calls SWR was getting. You know the ones where some guy calls asking if it will hold up to "insert random name"-short-ultra-win-magnum-X. The answer of "The suppressor in question is not rated for that caliber, nor do we have one of those on hand to test it" doesn't seem to matter to some people. Additional strengthening measures were implemented to keep everyone, to include those experimenters safe. Those ugly welds carry a lot of extra strength. In the end it's about keeping EVERYONE safe, even those who should know better.

SWR is using Mr. Burkes excellent TAB GEAR covers currently. Maybe that's why you haven't seen the recent changes on the new models. Might I also humbly suggest you encourage your customers to look at them as well. The mirage-reduction benefits, especially on a .300 Win Mag after a few rounds are nothing less than spectacular.

I hope this helps. I don't work for SWR. If you want I can get one of those guys to come on over and tell you the same thing.

Re: WTF SWR Omega 300

At the end of the day, all *I* care about is performance of said can. The SWR Omega 300 exceeded my expectations and then some. I am using this can on a .308, and I had never seen or shot a rifle with a can attached. The amount of recoil and sound reduction with the Omega 300 is drastic...to the point that it feels like I am shooting a reduced recoil 223. Neeless to say, I highly recommend it.

At the end of the day, all *I* care about is performance of said can. The SWR Omega 300 exceeded my expectations and then some. I am using this can on a .308, and I had never seen or shot a rifle with a can attached. The amount of recoil and sound reduction with the Omega 300 is drastic...to the point that it feels like I am shooting a reduced recoil 223. Neeless to say, I highly recommend it.

Re: WTF SWR Omega 300

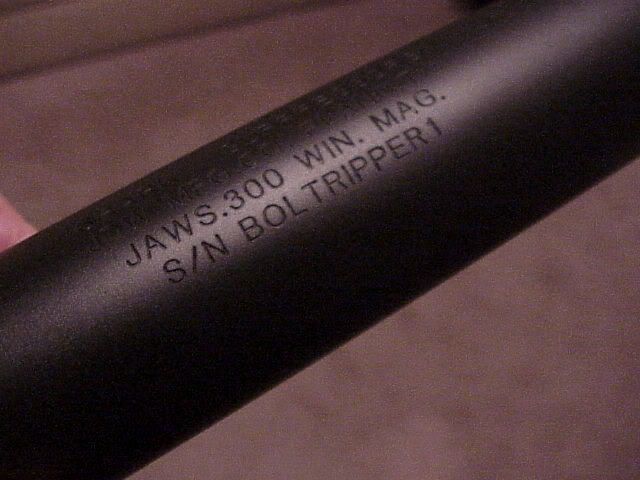

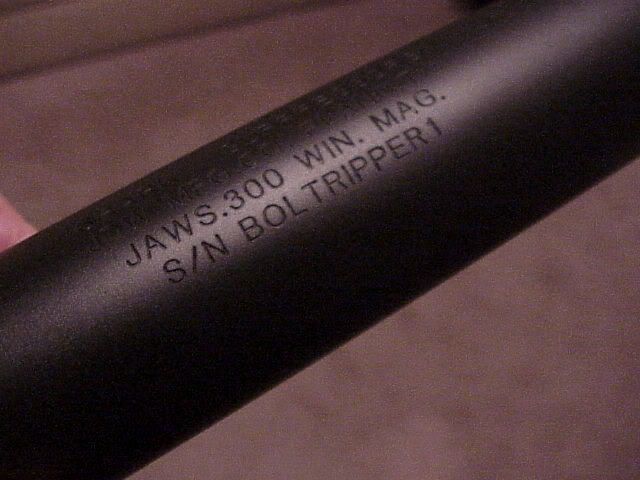

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: BOLTRIPPER</div><div class="ubbcode-body">....superior by design.....

</div></div>

</div></div>

Man your my hero!! You had your User ID put on your can. No thats COOL!!!

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: BOLTRIPPER</div><div class="ubbcode-body">....superior by design.....

Man your my hero!! You had your User ID put on your can. No thats COOL!!!

Re: WTF SWR Omega 300

I have a SWR Omega 300 coming, and I loved my 30 on my 308, so I can't imagine my 300 will disappoint, dimples or no dimples.

I have a SWR Omega 300 coming, and I loved my 30 on my 308, so I can't imagine my 300 will disappoint, dimples or no dimples.

Re: WTF SWR Omega 300

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Arevalosocom</div><div class="ubbcode-body">I have a SWR Omega 300 coming, and I loved my 30 on my 308, so I can't imagine my 300 will disappoint, dimples or no dimples. </div></div>

Yours will have dimples. Extra dimples actually. I will see to it personally...

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Arevalosocom</div><div class="ubbcode-body">I have a SWR Omega 300 coming, and I loved my 30 on my 308, so I can't imagine my 300 will disappoint, dimples or no dimples. </div></div>

Yours will have dimples. Extra dimples actually. I will see to it personally...

Re: WTF SWR Omega 300

I work in the steel industry . I inspect , and weld , on a daily basis ... I have met the owners of SWR , and seen their facilities . I will compliment them on their neatness and cleanliness , amongst other positives . They are dedicated to their customers and their product , IMHO . I own an OMEGA-300 , and I am impressed with its performance . They are welded on a jig , in a workman-like manner , in as a controlled-manner as is possible . Just realize that molten-steel is a bit unpredictable , and the welds might be slightly out-of-kilter . I suppose they could be welded heavy , and turned down flush , but that would not improve the performance , or cost . I own Randall knives , and Bagwell Bowies - they all show hammer-marks , which is a characteristic of hand-forged knives . Every knife-maker puts a little bit of his 'being' into his product , and I think Henry and his associates do the same . When I buy SWR , I'm not getting a 'run-of-the mill ' can , I'm getting a hand-crafted tool , that will last my lifetime and then some . I'm getting a state-of-the-art suppressor , with a little blood , sweat and tears added ...

I work in the steel industry . I inspect , and weld , on a daily basis ... I have met the owners of SWR , and seen their facilities . I will compliment them on their neatness and cleanliness , amongst other positives . They are dedicated to their customers and their product , IMHO . I own an OMEGA-300 , and I am impressed with its performance . They are welded on a jig , in a workman-like manner , in as a controlled-manner as is possible . Just realize that molten-steel is a bit unpredictable , and the welds might be slightly out-of-kilter . I suppose they could be welded heavy , and turned down flush , but that would not improve the performance , or cost . I own Randall knives , and Bagwell Bowies - they all show hammer-marks , which is a characteristic of hand-forged knives . Every knife-maker puts a little bit of his 'being' into his product , and I think Henry and his associates do the same . When I buy SWR , I'm not getting a 'run-of-the mill ' can , I'm getting a hand-crafted tool , that will last my lifetime and then some . I'm getting a state-of-the-art suppressor , with a little blood , sweat and tears added ...

Similar threads

- Replies

- 36

- Views

- 6K

- Replies

- 1

- Views

- 112