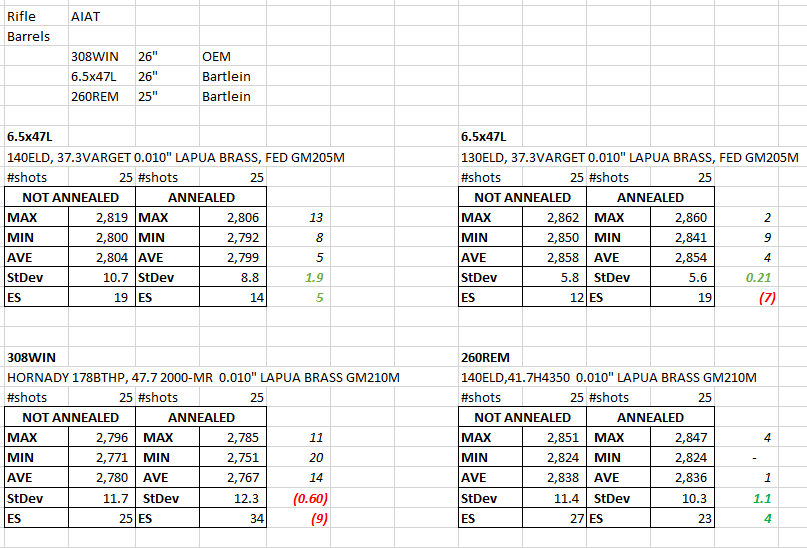

I started annealing with salt bath method few weeks ago and ran some annealed vs not annealed tests over the weekend with identical loads.

None of the brass (all Lapua) has ever been annealed before the test. I haven't kept track of number of firings but 260 has to be around 15 . Primer pockets are almost gone. 6.5x47 and 308 have probably been fired 8-10 times. Primer pockets for both are still tight specially the 6.5x47.

Brass has been prepped identical for both groups except annealing, and all powder/primer/brass/bullets are from the same lots and have been reloaded the same time.

There was no measurable difference between group size at 100 yards for annealed vs not. All shot around 1/2".

25shots were fired for each load w/MagnetospeedV3

None of the brass (all Lapua) has ever been annealed before the test. I haven't kept track of number of firings but 260 has to be around 15 . Primer pockets are almost gone. 6.5x47 and 308 have probably been fired 8-10 times. Primer pockets for both are still tight specially the 6.5x47.

Brass has been prepped identical for both groups except annealing, and all powder/primer/brass/bullets are from the same lots and have been reloaded the same time.

There was no measurable difference between group size at 100 yards for annealed vs not. All shot around 1/2".

25shots were fired for each load w/MagnetospeedV3