Hi all,

Here's the build to get that out of the way:

Aero Upper, Lower, handguard, and BCG (BCG weights 17.5 oz w/ HP bolt)

24" Wilson Combat super sniper barrel

Leapers UTG AR308 A2 Style Fixed Buttstock (came with buffer (5.2 oz), spring, and tube)

Superlative Arms AGB (rifle length system)

I have over 250 rds through it so far. Recently I started reloading my own ammo in the last 6 months, and have a sub-MOA load developed. Ultimately, I don't like the stock and I want to upgrade to the PRS. The Leapers buffer system origionally was, and still is very stiff. Bolt would not lock open with the gas block fully open. I shot about 50 rds allowing for an initial break-in, but nothing changed so I cut small portions of the spring in increments until I achieved reliable cycling and was able to adjust the gas block for the factory loads I was shooting at the time.

Overall, it treats brass okay. Not bad, not great. Tiny bit of primer cratering and flattening, but nothing excessive. I do get a little bit of bending at the rim where the extractor grabs the case. Anywhere from .001-.003". Worse with softer brass (Hornady). Sometimes there's ejector swipe, but sometimes there isn't. If there is it's also not excessive.

In the last 40 rounds or so I've had inconsistencies with the bolt locking back even with the AGB wide open as I was doing load dev and I like to keep it open for that. After reading this forum and others, I do believe that the buffer system can contribute to this issues and also the issues above in terms of brass treatment. I know in a gas gun I can't expect brass to come out beautiful, but I do believe there's room for improvement. I'd really like to limit the rim bending as it makes bullet seating inconsistent, and measuring true case length/headspace difficult. Since I'm changing the stock, I figured upgrading the buffer system should coincide. I'll also note that charging the rifle is very difficult from the spring tension. This is my first large frame AR, so maybe that's expected...

My request for advice is as follows:

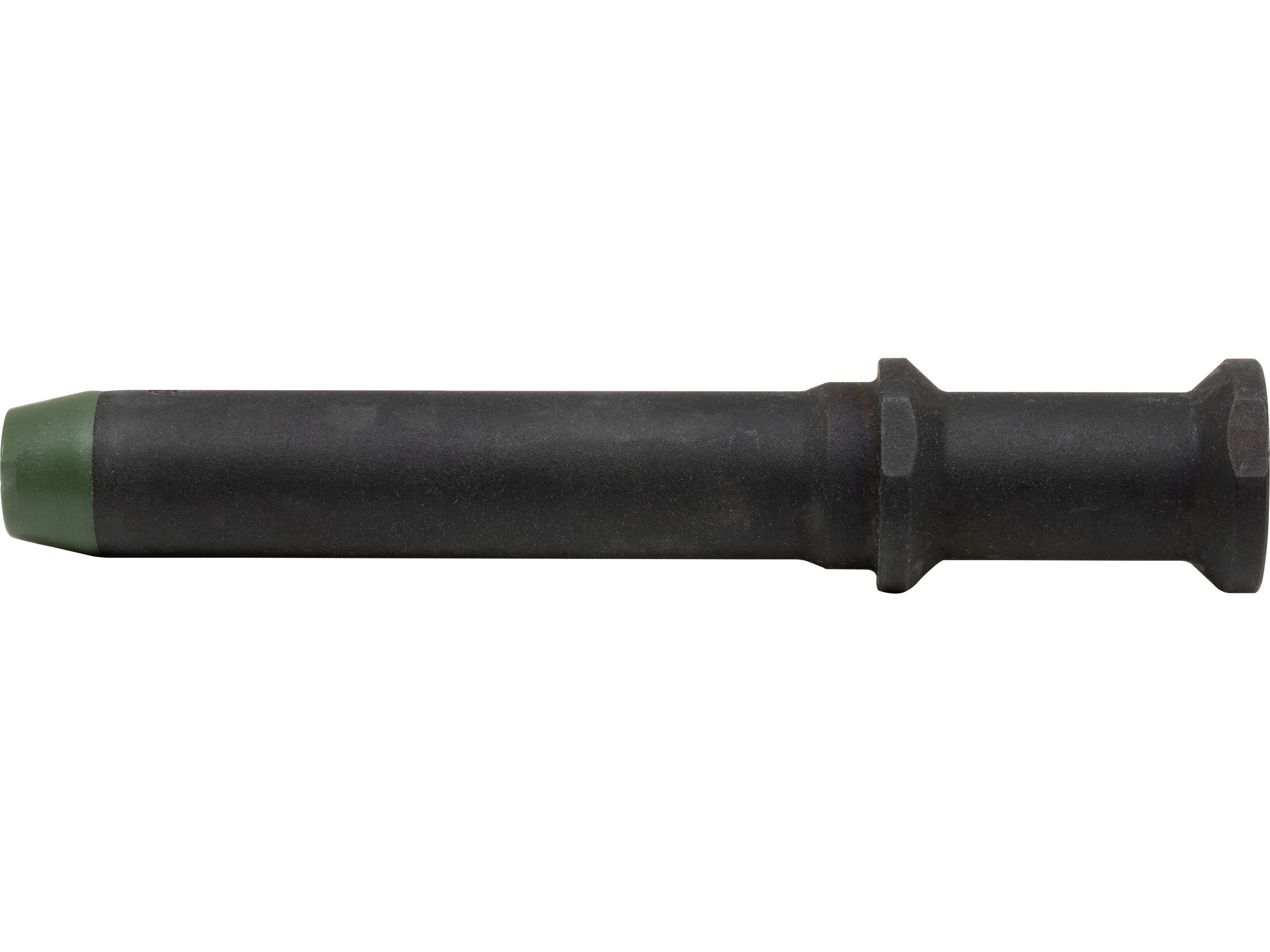

What should I be looking for in terms of buffer size/weight and the buffer spring itself? I find myself confused in most threads because people start talking about AR-15 buffer systems and I still don't understand the similarities and/or differences between AR-15 and AR-10 buffer systems. My current buffer is 5.2 oz.

People recommend the JP SCS, but I'm trying to avoid the $140-200 price tag for a buffer. I'm wondering if there's a more middle of the ground alternative. I'm not looking for budget parts as my stock and buffer system already is so to speak. If I do need to shell out the green backs to achieve what I want, then so be it.

This is my first post here. Thanks in advance for any forthcoming response. It's all appreciated.

-RT

Here's the build to get that out of the way:

Aero Upper, Lower, handguard, and BCG (BCG weights 17.5 oz w/ HP bolt)

24" Wilson Combat super sniper barrel

Leapers UTG AR308 A2 Style Fixed Buttstock (came with buffer (5.2 oz), spring, and tube)

Superlative Arms AGB (rifle length system)

I have over 250 rds through it so far. Recently I started reloading my own ammo in the last 6 months, and have a sub-MOA load developed. Ultimately, I don't like the stock and I want to upgrade to the PRS. The Leapers buffer system origionally was, and still is very stiff. Bolt would not lock open with the gas block fully open. I shot about 50 rds allowing for an initial break-in, but nothing changed so I cut small portions of the spring in increments until I achieved reliable cycling and was able to adjust the gas block for the factory loads I was shooting at the time.

Overall, it treats brass okay. Not bad, not great. Tiny bit of primer cratering and flattening, but nothing excessive. I do get a little bit of bending at the rim where the extractor grabs the case. Anywhere from .001-.003". Worse with softer brass (Hornady). Sometimes there's ejector swipe, but sometimes there isn't. If there is it's also not excessive.

In the last 40 rounds or so I've had inconsistencies with the bolt locking back even with the AGB wide open as I was doing load dev and I like to keep it open for that. After reading this forum and others, I do believe that the buffer system can contribute to this issues and also the issues above in terms of brass treatment. I know in a gas gun I can't expect brass to come out beautiful, but I do believe there's room for improvement. I'd really like to limit the rim bending as it makes bullet seating inconsistent, and measuring true case length/headspace difficult. Since I'm changing the stock, I figured upgrading the buffer system should coincide. I'll also note that charging the rifle is very difficult from the spring tension. This is my first large frame AR, so maybe that's expected...

My request for advice is as follows:

What should I be looking for in terms of buffer size/weight and the buffer spring itself? I find myself confused in most threads because people start talking about AR-15 buffer systems and I still don't understand the similarities and/or differences between AR-15 and AR-10 buffer systems. My current buffer is 5.2 oz.

People recommend the JP SCS, but I'm trying to avoid the $140-200 price tag for a buffer. I'm wondering if there's a more middle of the ground alternative. I'm not looking for budget parts as my stock and buffer system already is so to speak. If I do need to shell out the green backs to achieve what I want, then so be it.

This is my first post here. Thanks in advance for any forthcoming response. It's all appreciated.

-RT