A friend who uses his in Tac so a 3000fps max uses N135 and another guy I know uses N140 so those might be a better place to get more velocity. I was hoping N150 so I could cross use with the .308 easier.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.223 - 5.56

- Thread starter Two Shoes

- Start date

I'm interested in a VV powder that would do well in 223 and 308 also. I see a lot of people sub N140 for varget, which works well in both of them, but there are quite a few that use N150 in 308. Does the 150 work better with the 175 class of bullets?A friend who uses his in Tac so a 3000fps max uses N135 and another guy I know uses N140 so those might be a better place to get more velocity. I was hoping N150 so I could cross use with the .308 easier.

A friend who uses his in Tac so a 3000fps max uses N135 and another guy I know uses N140 so those might be a better place to get more velocity. I was hoping N150 so I could cross use with the .308 easier.

Man, I've got a bunch of N135 too for general heavier .233 and Grendel loads. I might have to give this a shot soon.

Like you, I found that N150 works with a lot of stuff. I've got excellent loads for the 6.5x47, 6GT, and (maybe) now .223. I'll have to monkey around with it in .308 too just for grins.

I'm interested in a VV powder that would do well in 223 and 308 also. I see a lot of people sub N140 for varget, which works well in both of them, but there are quite a few that use N150 in 308. Does the 150 work better with the 175 class of bullets?

Not sure honestly but it looks like it would do well from their data. I have some N140 so may try it in the .308 and see what it will do first.

N140 is almost a drop-in replacement for Varget. N150 should be better with heavier bullets in the .308.

Id be curious if N140 could push a heavier 308 say a 185 or something along those lines. If I could cross use my N140 with 77gr and 185gr bergers that would be amazing.Not sure honestly but it looks like it would do well from their data. I have some N140 so may try it in the .308 and see what it will do first.

That's what I'm looking for. Something that will crossover with the 77's in 223 and the 169 to 178 in a 20" 308. I'm using varget now but VV is cheaper.Id be curious if N140 could push a heavier 308 say a 185 or something along those lines. If I could cross use my N140 with 77gr and 185gr bergers that would be amazing.

I get good results with vv140 with 77 gr smk in the 223 and 155 palma in the 308. I tried heavy in the 308 with it but had better luck with other powders.

I just read a post in the .308 thread where the guy had great luck with N150. I know this is the .223 thread, but there have been some ponderings about the crossover ability with this powder.

My brother and I decided to order some N540 last night. We decided to go that route instead of the N150. I didn't look at the data but he said the 150 didn't look favorable in the 223 until you got over an 80gr bullet. The N540 was about 150fps faster than the N140 from what he told me. He'll cover the 223 with 77's out of a 16" tikka t3x. Right now he's knocking on 2600 with varget and a 77 tmk.

I'll shoot the 308 out of my custom 700 with a 20" 1:9 lilja. I'll have to see what I've got left in the 175/178gr bullets. I may be down to 168's. I know I've got smk's and Amax, maybe some eld-m's. Been burning up all the loose ends lately. I think I'm going to settle on the 169 smk for 308 and the 77 smk and the tmk when I can get them in the 223.

I'll shoot the 308 out of my custom 700 with a 20" 1:9 lilja. I'll have to see what I've got left in the 175/178gr bullets. I may be down to 168's. I know I've got smk's and Amax, maybe some eld-m's. Been burning up all the loose ends lately. I think I'm going to settle on the 169 smk for 308 and the 77 smk and the tmk when I can get them in the 223.

75 elds going near 3000 fps own everything inside 800y and can shoot much farther but impact becomes an issue unless using flashers or a good spotter.You can with a different powder but interested in the N150 also as they are priced right now. With XBR or Varget I get close to 3000fps with 75 ELDs in my 27” .223 Wylde. If I could get some VV that can do it I would be happy.

I was doing 24.5 gr of XBR, loaded long in a much longer throat than wylde. Winchester brass gave up after a few firings though. If I were to use that combo again I would drop the charge .2gr or so.

75 elds going near 3000 fps own everything inside 800y and can shoot much farther but impact becomes an issue unless using flashers or a good spotter.

I was doing 24.5 gr of XBR, loaded long in a much longer throat than wylde. Winchester brass gave up after a few firings though. If I were to use that combo again I would drop the charge .2gr or so.

Yup I have shot them out to 1150 at a match and they are hard to hear at those distances.

75gr ELD-M/ N150. Load specs are above in this page a couple times.

Shot a 10 shot group (pink dot) just now in pretty crappy conditions (39*, W 13MPH according to the Weather Channel). The green dot was an old 69gr SMK / Reloader 15 load test...I just re-used an old target. Please ignore.

Chronograph read 2,801 / 30 ES / 11 SD. I didn't have the ammo out in the cold for too long (20 mins?), so at least it is initially looking like N150 is a tad temp sensitive as it lost 17 FPS from when the ammo was sitting out in ~62 degree weather. I'll need to control and measure this better. Prior to shooting, it sat in a house with the thermostat set at 68 degrees.

I did pull one shot...but looking at the target now (blown up), it looks like I put another shot in there too??...so I'm sticking with that .604 group, and not leaning on an excuse.

*** I'm out of 75gr ELD-Ms at the moment, but will resume this testing when it warms up. I'm curious to see if 1) velocity increases when I store and shoot the ammo at 80 degrees F, and 2) If accuracy tightens up a bit when the load is a tad warmer.

Shot a 10 shot group (pink dot) just now in pretty crappy conditions (39*, W 13MPH according to the Weather Channel). The green dot was an old 69gr SMK / Reloader 15 load test...I just re-used an old target. Please ignore.

Chronograph read 2,801 / 30 ES / 11 SD. I didn't have the ammo out in the cold for too long (20 mins?), so at least it is initially looking like N150 is a tad temp sensitive as it lost 17 FPS from when the ammo was sitting out in ~62 degree weather. I'll need to control and measure this better. Prior to shooting, it sat in a house with the thermostat set at 68 degrees.

I did pull one shot...but looking at the target now (blown up), it looks like I put another shot in there too??...so I'm sticking with that .604 group, and not leaning on an excuse.

*** I'm out of 75gr ELD-Ms at the moment, but will resume this testing when it warms up. I'm curious to see if 1) velocity increases when I store and shoot the ammo at 80 degrees F, and 2) If accuracy tightens up a bit when the load is a tad warmer.

Last edited:

How long is your barrell?75gr ELD-M/ N150. Load specs are above in this page a couple times.

Shot a 10 shot group (pink dot) just now in pretty crappy conditions (39*, W 13MPH according to the Weather Channel). The green dot was an old 69gr SMK / Reloader 15 load test...I just re-used an old target. Please ignore.

Chronograph read 2,801 / 30 ES / 11 SD. I didn't have the ammo out in the cold for too long (20 mins?), so at least it is initially looking like N150 is a tad temp sensitive as it lost 17 FPS from when the ammo was sitting out in ~62 degree weather. I'll need to control and measure this better. Prior to shooting, it sat in a house with the thermostat set at 68 degrees.

I did pull one shot...but looking at the target now (blown up), it looks like I put another shot in there too??...so I'm sticking with that .604 group, and not leaning on an excuse.

*** I'm out of 75gr ELD-Ms at the moment, but will resume this testing when it warms up. I'm curious to see if 1) velocity increases when I store and shoot the ammo at 80 degrees F, and 2) If accuracy tightens up a bit when the load is a tad warmer.

View attachment 8615782

**edit this is a gas gun**

Hopefully some one can correct me or show my where I am missing something.

I am wanting get a 20in barrel with a Wylde chamber. And be able to shoot to the maximum of my range, 820 yards, with “decent” repeatability. *I understand the 6 arc would be better suited for this.*

I’m at about 800ft above sea level for reference.

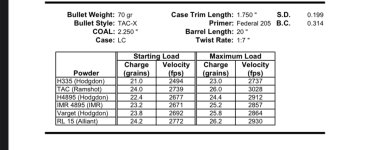

The load data I am seeing leads me to believe this is possible, some show 70gr some show 77gr. But the overall theme I see is, you can get them moving fast enough to make it happen.

But I don’t hear many people talking about it either.

I feel like if I can get a 75gr BTHP moving at about 2850 then I should be good. And the seems obtainable based upon what I am seeing in the attached load data.

I do like my face, so I’d prefer to keep it intact.

Thanks.

Hopefully some one can correct me or show my where I am missing something.

I am wanting get a 20in barrel with a Wylde chamber. And be able to shoot to the maximum of my range, 820 yards, with “decent” repeatability. *I understand the 6 arc would be better suited for this.*

I’m at about 800ft above sea level for reference.

The load data I am seeing leads me to believe this is possible, some show 70gr some show 77gr. But the overall theme I see is, you can get them moving fast enough to make it happen.

But I don’t hear many people talking about it either.

I feel like if I can get a 75gr BTHP moving at about 2850 then I should be good. And the seems obtainable based upon what I am seeing in the attached load data.

I do like my face, so I’d prefer to keep it intact.

Thanks.

Attachments

What specific barrel brands are you looking at? Id imagine you’re looking at Proof, White Oak, etc. stainless barrels? For chrome lined chrome moly barrels Criterion core is a solid option.**edit this is a gas gun**

Hopefully some one can correct me or show my where I am missing something.

I am wanting get a 20in barrel with a Wylde chamber. And be able to shoot to the maximum of my range, 820 yards, with “decent” repeatability. *I understand the 6 arc would be better suited for this.*

I’m at about 800ft above sea level for reference.

The load data I am seeing leads me to believe this is possible, some show 70gr some show 77gr. But the overall theme I see is, you can get them moving fast enough to make it happen.

But I don’t hear many people talking about it either.

I feel like if I can get a 75gr BTHP moving at about 2850 then I should be good. And the seems obtainable based upon what I am seeing in the attached load data.

I do like my face, so I’d prefer to keep it intact.

Thanks.

It’s definitely doable but good luck spotting your impacts/misses at that range with a .224 bullet if you dont have a spotter. The repeatability will be largely dependent on the quality of the handloads, quality of the barrel you choose, whether or not you purchased a quality bolt headspaced to the barrel, and the overall build quality of your gun (factory build, built by you from scratch with all proper torque values, etc.).

For bullets id look at the 73gr ELD-M due to its better BC compared to 75 BTHP plus it fits in AR mags (it has one of the best BC’s while still being able to fit in AR mags). There’s also the Berger and Sierra 77gr OTM which are both fantastic for long range shooting but their BC is slightly worse than the 73 ELD-M.

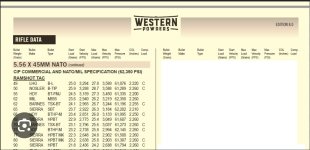

To give you some idea of recommended bullets and powders for 223 long distance shooting (note the COAL listed for some of these bullets, i.e. the 75 ELD-M are only for single feeding/bolt guns bc they’re too long for gas gun mag length) from the Lyman long range precision rifle reloading handbook:

Last edited:

Thanks!What specific barrel brands are you looking at? Id imagine you’re looking at Proof, White Oak, etc. stainless barrels? For chrome lined chrome moly barrels Criterion core is a solid option.

It’s definitely doable but good luck spotting your impacts/misses at that range with a .224 bullet if you dont have a spotter. The repeatability will be largely dependent on the quality of the handloads, quality of the barrel you choose, whether or not you purchased a quality bolt headspaced to the barrel, and the overall build quality of your gun (factory build, built by you from scratch with all proper torque values, etc.).

For bullets id look at the 73gr ELD-M due to its better BC compared to 75 BTHP plus it fits in AR mags (it has one of the best BC’s while still being able to fit in AR mags). There’s also the Berger and Sierra 77gr OTM which are both fantastic for long range shooting but their BC is slightly worse than the 73 ELD-M.

To give you some idea of recommended bullets and powders for 223 long distance shooting (note the COAL listed for some of these bullets, i.e. the 75 ELD-M are only for single feeding/bolt guns bc they’re too long for gas gun mag length) from the Lyman long range precision rifle

Looking at a craddock with a rock creek blank. With them providing the bolt. Figured it was the best starting point!

I could put it In an aero enhanced upper or a VLTOR. I’m undecided at this point.

73 ELD-M looks promising. And I’m surprised Varget does as well as it shows in that handbook.

But definitely worth a look

You’re welcome. Nice, the craddock/rock creek should get the job done nicely especially with a headspaced bolt.Thanks!

Looking at a craddock with a rock creek blank. With them providing the bolt. Figured it was the best starting point!

I could put it In an aero enhanced upper or a VLTOR. I’m undecided at this point.

73 ELD-M looks promising. And I’m surprised Varget does as well as it shows in that handbook.

But definitely worth a look

Another upper to consider would be a stripped blem BCM (its a nice tight thermofit with the barrel), pretty good deal for around $80

Here’s a list of solid options I consider for precision ar15 builds:

- BCM Blemished Upper Receiver Kit (includes fwd assist, etc.) ($80)

- Midwest Complete Forged Upper Receiver ($120)

- VLTOR MUR Upper with fwd assit ($190)

- JP Stripped Forged Upper Receiver ($175)

- White Oak Complete Forged AR Upper ($120)

- FCD Forged Upper ($130)

I’ll check those out, thanks for the detail and links!You’re welcome. Nice, the craddock/rock creek should get the job done nicely especially with a headspaced bolt.

Another upper to consider would be a stripped blem BCM (its a nice tight thermofit with the barrel), pretty good deal for around $80

Here’s a list of solid options I consider for precision ar15 builds:

- BCM Blemished Upper Receiver Kit (includes fwd assist, etc.) ($80)

- Midwest Complete Forged Upper Receiver ($120)

- VLTOR MUR Upper with fwd assit ($190)

- JP Stripped Forged Upper Receiver ($175)

- White Oak Complete Forged AR Upper ($120)

- FCD Forged Upper ($130)

I’ll see what I can find as far as data goes.

I assume I can use 5.56 load data if it is once fired brass from my chamber?

I have some loaded Bergers, in 223 Lapua brass, as long as the primers don’t pierce. I’ve read on here one lot was pretty hot and gave a guy a lot of trouble

I remember reading something similar about loaded bergers so def be careful with them.I’ll check those out, thanks for the detail and links!

I’ll see what I can find as far as data goes.

I assume I can use 5.56 load data if it is once fired brass from my chamber?

I have some loaded Bergers, in 223 Lapua brass, as long as the primers don’t pierce. I’ve read on here one lot was pretty hot and gave a guy a lot of trouble

You can confirm with craddock re: whether or not your chamber will handle 5.56 pressures but 223 wylde should be able to handle it. If you dont have some already Id def get some go headspace gauges for 223 (1.4636”) and 5.56 (1.4646”) to verify exactly how much headspace your chamber actually has regardless of how its marked on the outside or what Craddock says.

For example does it close on 223 go? Does it close on 5.56 go? If it feels like it can barely close on the 223 go gauge you may have a slightly tight 223 wylde chamber and Id be careful of loading 5.56 pressures. As always start low and work your way up. A wylde chamber should close on 1.4636 but not on 1.4646 (its supposed to have headspace in between 223 and 5.56 but I dont know the exact spec off hand). You can keep adding pieces of scotch tape to the 223 go gauge until it stops closing and use that as an estimate. Each layer of tape is a little over .002” thick.

Note the load data in the pics I provided is based on 223 pressures not 5.56 so you could use them as starting points and go up from there.

I've been thinking about neck tension and crimping 5.56x45mm.

My die is setup with a bushing to size LC brass necks to .243" and then pull a carbide expander ball through them to leave an OD of .244". When I seat a bullet, the OD is .0246". This would be commonly referred to as two thou of "neck tension." The amount of tension also depends on how much of the deformation the brass undergoes when the bullet is inserted is plastic and how much is elastic. My brass was brand-new Winchester brand from Lake City, fired and resized only once by me. I haven't messed it up with improper annealing nor have I work-hardened the brass neck by resizing it many times. I'll refer to this two thou delta between sized and seated as two thou of neck tension with the understanding that there's a little more involved there.

Bullet Jump

With two thou of neck tension and no crimp holding the bullet, I measured the overall length and then let the action on the rifle strip it from the magazine and slam it into battery with the muzzle pointed down. I measured it again and saw the bullet had jumped 1 thou. The cartridges I'm using for these tests have no powder or primer. Because the rifle has a floating firing pin, I did not want to be trying to induce a slam fire. I'm not surprised the bullet jumped because when a semi-automatic action accelerates the cartridge toward the chamber and then abruptly stops when the breech closes, it works just like an inertial bullet pulling hammer hit against a hard surface. Newton's first law explains why the bullet, once accelerated, will continue in motion even if the brass is stopped. Friction in the brass case neck is the only thing stopping the bullet from continuing until it hits the lands, unless it is crimped. The friction was enough to allow the bullet to jump only one thou. However, I repeated chambering the same cartridge several times and the bullet continued to jump 1 or 1.5 thou each time.

Crimp Test

Next, I used a Redding micro-adjustable taper crimp die to crimp the case of a different cartridge in the bullet's crimp groove. I repeated the process of measuring the overall length, chambering the round with the full force of the action, and measuring how far the bullet jumped. With the crimp, the bullet still jumped a thou. However, when I repeatedly chambered the same cartridge, the bullet jumped a total of three thou and then stopped moving farther with subsequent chamberings. I suspect the edge of the crimp groove slid forward against the crimp, and that it would take more force to push the crimp open.

More Neck Tension

To get more neck tension, I first removed the carbide expander ball from the die. Now the brass would be .243" before seating the bullet and .246" after -- three thou of neck tension. I also selected a different brand brass, a Speer nickel-plated case, and after sizing it with the .243" bushing without expanding it and then seating a bullet, it measured .247". The Speer case's brass is thicker in the neck -- four thou of neck tension. I repeated the tests on uncrimped cartridges and found the bullets would still slide forward about a thou every time they were slammed into battery. The bullet in the Speer case continued to jump as far forward as eight thou with repeating chamberings.

Crimp + More Neck Tension

I resized cases and seated bullets with 3 and 4 thou neck tension, and this time I also crimped them. I repeated the tests. I found the bullets would jump a thou, and after repeated chamberings they had jumped about three thou. After that, they would not jump farther.

Conclusion

My results suggest to me that increased neck tension will not stop bullet jump. I don't have more bushings to test 5 or 6 thou or more of neck tension, but at some point seating the bullet is going to plastically deform the neck so that it is not actually holding the bullet under any additional spring tension than that which is achieved with a larger bushing.

My results suggest a crimp will not stop all bullet jump, but that a crimp into a crimp groove can limit bullet jump to some smaller distance within the groove provided the inertial force on the bullet does not overcome the crimp. Certainly, my hammer-style bullet puller will overcome the crimp.

Not all bullets have a crimp groove. Many more accurate bullets do not because pressed crimp grooves deform the bullet and result in poor mass concentricity and wobbly bullets. Perhaps crimp grooves cut into a solid bullet on a lathe do not create this problem. Certainly, bullets into which a crimp groove is smashed by a Factory Crimp Die do. For bullets without a crimp groove, it seems best practice not the crimp them and to be aware they can jump some when slammed into battery by a semi-automatic action. If they jump one thou, that doesn't seem to be a big problem to me.

If a bullet has a crimp groove, a taper crimp of the case mouth into the groove can help limit the distance of bullet jump from the cartridge being slammed into battery. However, unless the cartridge is expected to be repeatedly slammed into battery many times, it's not clear that any benefit is derived from the crimp since the crimp is not likely to prevent the 1 or 1.5 thou the bullet is likely to jump upon being chambered the first time, and any ability of the crimp to limit further jump upon additional chamberings won't matter after the cartridge is fired. It could matter more if the recoil spring rate was greater. The M249 uses a piston operated gas system with a greater reciprocating mass, fires from an open-bolt, and has a higher rate of fire that is expected to be sustained for longer. It is highly likely therefore that it has a higher recoil spring rate, and that the cartridge is accelerated to a higher velocity before it is stopped in battery.

Questions

My die is setup with a bushing to size LC brass necks to .243" and then pull a carbide expander ball through them to leave an OD of .244". When I seat a bullet, the OD is .0246". This would be commonly referred to as two thou of "neck tension." The amount of tension also depends on how much of the deformation the brass undergoes when the bullet is inserted is plastic and how much is elastic. My brass was brand-new Winchester brand from Lake City, fired and resized only once by me. I haven't messed it up with improper annealing nor have I work-hardened the brass neck by resizing it many times. I'll refer to this two thou delta between sized and seated as two thou of neck tension with the understanding that there's a little more involved there.

Bullet Jump

With two thou of neck tension and no crimp holding the bullet, I measured the overall length and then let the action on the rifle strip it from the magazine and slam it into battery with the muzzle pointed down. I measured it again and saw the bullet had jumped 1 thou. The cartridges I'm using for these tests have no powder or primer. Because the rifle has a floating firing pin, I did not want to be trying to induce a slam fire. I'm not surprised the bullet jumped because when a semi-automatic action accelerates the cartridge toward the chamber and then abruptly stops when the breech closes, it works just like an inertial bullet pulling hammer hit against a hard surface. Newton's first law explains why the bullet, once accelerated, will continue in motion even if the brass is stopped. Friction in the brass case neck is the only thing stopping the bullet from continuing until it hits the lands, unless it is crimped. The friction was enough to allow the bullet to jump only one thou. However, I repeated chambering the same cartridge several times and the bullet continued to jump 1 or 1.5 thou each time.

Crimp Test

Next, I used a Redding micro-adjustable taper crimp die to crimp the case of a different cartridge in the bullet's crimp groove. I repeated the process of measuring the overall length, chambering the round with the full force of the action, and measuring how far the bullet jumped. With the crimp, the bullet still jumped a thou. However, when I repeatedly chambered the same cartridge, the bullet jumped a total of three thou and then stopped moving farther with subsequent chamberings. I suspect the edge of the crimp groove slid forward against the crimp, and that it would take more force to push the crimp open.

More Neck Tension

To get more neck tension, I first removed the carbide expander ball from the die. Now the brass would be .243" before seating the bullet and .246" after -- three thou of neck tension. I also selected a different brand brass, a Speer nickel-plated case, and after sizing it with the .243" bushing without expanding it and then seating a bullet, it measured .247". The Speer case's brass is thicker in the neck -- four thou of neck tension. I repeated the tests on uncrimped cartridges and found the bullets would still slide forward about a thou every time they were slammed into battery. The bullet in the Speer case continued to jump as far forward as eight thou with repeating chamberings.

Crimp + More Neck Tension

I resized cases and seated bullets with 3 and 4 thou neck tension, and this time I also crimped them. I repeated the tests. I found the bullets would jump a thou, and after repeated chamberings they had jumped about three thou. After that, they would not jump farther.

Conclusion

My results suggest to me that increased neck tension will not stop bullet jump. I don't have more bushings to test 5 or 6 thou or more of neck tension, but at some point seating the bullet is going to plastically deform the neck so that it is not actually holding the bullet under any additional spring tension than that which is achieved with a larger bushing.

My results suggest a crimp will not stop all bullet jump, but that a crimp into a crimp groove can limit bullet jump to some smaller distance within the groove provided the inertial force on the bullet does not overcome the crimp. Certainly, my hammer-style bullet puller will overcome the crimp.

Not all bullets have a crimp groove. Many more accurate bullets do not because pressed crimp grooves deform the bullet and result in poor mass concentricity and wobbly bullets. Perhaps crimp grooves cut into a solid bullet on a lathe do not create this problem. Certainly, bullets into which a crimp groove is smashed by a Factory Crimp Die do. For bullets without a crimp groove, it seems best practice not the crimp them and to be aware they can jump some when slammed into battery by a semi-automatic action. If they jump one thou, that doesn't seem to be a big problem to me.

If a bullet has a crimp groove, a taper crimp of the case mouth into the groove can help limit the distance of bullet jump from the cartridge being slammed into battery. However, unless the cartridge is expected to be repeatedly slammed into battery many times, it's not clear that any benefit is derived from the crimp since the crimp is not likely to prevent the 1 or 1.5 thou the bullet is likely to jump upon being chambered the first time, and any ability of the crimp to limit further jump upon additional chamberings won't matter after the cartridge is fired. It could matter more if the recoil spring rate was greater. The M249 uses a piston operated gas system with a greater reciprocating mass, fires from an open-bolt, and has a higher rate of fire that is expected to be sustained for longer. It is highly likely therefore that it has a higher recoil spring rate, and that the cartridge is accelerated to a higher velocity before it is stopped in battery.

Questions

- Do bullets in 5.56x45 cartridges jump when chambered in your semi-automatic rifle? If so, how much?

- How much delta is there between your sized and seated necks?

- Do you crimp your cases when the bullet has a crimp groove? If so, taper or roll?

- If you crimp your cases, why do you do so? Have you done any tests to verify that it is effective?

What’s the current word on the street with Staball match ? Is it kind of a TAC substitute except it’s a bit more temp stable ?

I get can both for about the same price. Planning to load 77TMK at 2.475in out of a 20in bolt gun at 60K psi.

I can also get N540 for a small premium.

I get can both for about the same price. Planning to load 77TMK at 2.475in out of a 20in bolt gun at 60K psi.

I can also get N540 for a small premium.

In my experience, StaBALL Match is bulky for 223. I don't have TAC, but I suspect it is not nearly as bulky. I could only get enough of StaBALL Match under a 55-grain bullet if I compressed it quite a bit. On the burn rate chart, it's closer to BL-C(2) and CFE 223. 77, 80 and 90 grain bullets are the only ones Hodgdon lists without indicating a compressed load. It could work with those heavier bullets, but I have not tried.

I was going to read all that but decided to go put in a full day of work instead.I've been thinking about neck tension and crimping 5.56x45mm.

My die is setup with a bushing to size LC brass necks to .243" and then pull a carbide expander ball through them to leave an OD of .244". When I seat a bullet, the OD is .0246". This would be commonly referred to as two thou of "neck tension." The amount of tension also depends on how much of the deformation the brass undergoes when the bullet is inserted is plastic and how much is elastic. My brass was brand-new Winchester brand from Lake City, fired and resized only once by me. I haven't messed it up with improper annealing nor have I work-hardened the brass neck by resizing it many times. I'll refer to this two thou delta between sized and seated as two thou of neck tension with the understanding that there's a little more involved there.

Bullet Jump

With two thou of neck tension and no crimp holding the bullet, I measured the overall length and then let the action on the rifle strip it from the magazine and slam it into battery with the muzzle pointed down. I measured it again and saw the bullet had jumped 1 thou. The cartridges I'm using for these tests have no powder or primer. Because the rifle has a floating firing pin, I did not want to be trying to induce a slam fire. I'm not surprised the bullet jumped because when a semi-automatic action accelerates the cartridge toward the chamber and then abruptly stops when the breech closes, it works just like an inertial bullet pulling hammer hit against a hard surface. Newton's first law explains why the bullet, once accelerated, will continue in motion even if the brass is stopped. Friction in the brass case neck is the only thing stopping the bullet from continuing until it hits the lands, unless it is crimped. The friction was enough to allow the bullet to jump only one thou. However, I repeated chambering the same cartridge several times and the bullet continued to jump 1 or 1.5 thou each time.

Crimp Test

Next, I used a Redding micro-adjustable taper crimp die to crimp the case of a different cartridge in the bullet's crimp groove. I repeated the process of measuring the overall length, chambering the round with the full force of the action, and measuring how far the bullet jumped. With the crimp, the bullet still jumped a thou. However, when I repeatedly chambered the same cartridge, the bullet jumped a total of three thou and then stopped moving farther with subsequent chamberings. I suspect the edge of the crimp groove slid forward against the crimp, and that it would take more force to push the crimp open.

More Neck Tension

To get more neck tension, I first removed the carbide expander ball from the die. Now the brass would be .243" before seating the bullet and .246" after -- three thou of neck tension. I also selected a different brand brass, a Speer nickel-plated case, and after sizing it with the .243" bushing without expanding it and then seating a bullet, it measured .247". The Speer case's brass is thicker in the neck -- four thou of neck tension. I repeated the tests on uncrimped cartridges and found the bullets would still slide forward about a thou every time they were slammed into battery. The bullet in the Speer case continued to jump as far forward as eight thou with repeating chamberings.

Crimp + More Neck Tension

I resized cases and seated bullets with 3 and 4 thou neck tension, and this time I also crimped them. I repeated the tests. I found the bullets would jump a thou, and after repeated chamberings they had jumped about three thou. After that, they would not jump farther.

Conclusion

My results suggest to me that increased neck tension will not stop bullet jump. I don't have more bushings to test 5 or 6 thou or more of neck tension, but at some point seating the bullet is going to plastically deform the neck so that it is not actually holding the bullet under any additional spring tension than that which is achieved with a larger bushing.

My results suggest a crimp will not stop all bullet jump, but that a crimp into a crimp groove can limit bullet jump to some smaller distance within the groove provided the inertial force on the bullet does not overcome the crimp. Certainly, my hammer-style bullet puller will overcome the crimp.

Not all bullets have a crimp groove. Many more accurate bullets do not because pressed crimp grooves deform the bullet and result in poor mass concentricity and wobbly bullets. Perhaps crimp grooves cut into a solid bullet on a lathe do not create this problem. Certainly, bullets into which a crimp groove is smashed by a Factory Crimp Die do. For bullets without a crimp groove, it seems best practice not the crimp them and to be aware they can jump some when slammed into battery by a semi-automatic action. If they jump one thou, that doesn't seem to be a big problem to me.

If a bullet has a crimp groove, a taper crimp of the case mouth into the groove can help limit the distance of bullet jump from the cartridge being slammed into battery. However, unless the cartridge is expected to be repeatedly slammed into battery many times, it's not clear that any benefit is derived from the crimp since the crimp is not likely to prevent the 1 or 1.5 thou the bullet is likely to jump upon being chambered the first time, and any ability of the crimp to limit further jump upon additional chamberings won't matter after the cartridge is fired. It could matter more if the recoil spring rate was greater. The M249 uses a piston operated gas system with a greater reciprocating mass, fires from an open-bolt, and has a higher rate of fire that is expected to be sustained for longer. It is highly likely therefore that it has a higher recoil spring rate, and that the cartridge is accelerated to a higher velocity before it is stopped in battery.

Questions

- Do bullets in 5.56x45 cartridges jump when chambered in your semi-automatic rifle? If so, how much?

- How much delta is there between your sized and seated necks?

- Do you crimp your cases when the bullet has a crimp groove? If so, taper or roll?

- If you crimp your cases, why do you do so? Have you done any tests to verify that it is effective?

I would compare it more to Varget just in ball powder form. Meters very well in my RCBS powder thrower and really speeds up the reloading process.What’s the current word on the street with Staball match ? Is it kind of a TAC substitute except it’s a bit more temp stable ?

I get can both for about the same price. Planning to load 77TMK at 2.475in out of a 20in bolt gun at 60K psi.

I can also get N540 for a small premium.

My bolt gun load is 26 grains in LC 556 brass, 75 grain ELD at 2.495 OAL. Getting 2937 fps at 60f and 2925 at 30f out of 26” PVA prefit. Standard deviation is around 10, pretty good for 223 in my experience.

Thanks. I tested 26.5gr in LC233 brass with the 77TMK at 2.475in just for a quick pressure test to see if my burn rate matched my modified quick load data and I got 2990fps on my Garmin X1 which is about 75fps faster than 24.3 varget in the same 26in IBI barrel.I would compare it more to Varget just in ball powder form. Meters very well in my RCBS powder thrower and really speeds up the reloading process.

My bolt gun load is 26 grains in LC 556 brass, 75 grain ELD at 2.495 OAL. Getting 2937 fps at 60f and 2925 at 30f out of 26” PVA prefit. Standard deviation is around 10, pretty good for 223 in my experience.

Looking to get 2800-2850 out my next barrel in 20in.

I have some Starline 556 and LC556 brass on the way. Planning to run 25.8 with the 80.5 and 26.3 with the 77tmk.

According to QL, It’s a tad faster burning than varget and a slightly better burn in the 16-20in barrel and isn’t temp sensitive like TAC.

Just finished up an old jug of powder for my 223 bolt gun that I bought years ago and then put away and didn’t use for a long time after I sold my last AR. Was shocked to see what I paid for it. Primers were around 2 or 3 cents each at the time if I remember correctly.

Attachments

Last edited:

What's your COAL?First try at reloading, all seems to have gone well!

Tikka .223 with a 20" Proof CF Prefit

New Norma Brass

25.5gr CFE223

75gr ELD-M

Avg Velocity was 2740.8 FPS

ES 31.7

SD 8.8

Primers looked great at this charge, at 26.0 they flattened out.

View attachment 8647536

I was shooting for 2.468”What's your COAL?

I picked up some of the 75 Grain Black Poly Tip bullets for super cheap to use in the AR, but thought I would give them a try in my bolt gun with an 18" 1:7 KAK Remage barrel

24.9 N540

2.265" COAL, slight powder crunch when seating.

5 shots were sub MOA on a 545 yard target

24.9 N540

2.265" COAL, slight powder crunch when seating.

5 shots were sub MOA on a 545 yard target

20" white oak barrel

.223 chamber

Lake city brass

Cci400

22.5 grains of h335

Hornady 75grn bthp @2.2500 Hornady 80gr match @ 2.4745

75s are running about 2780

80s at at 2600

The 80s are single load only, not a chance they are going in a mag.I just started loading for the 80s so I haven't tried going up yet, but they shot well in my last highpower match. They are currently about 10 thou from the lands

.223 chamber

Lake city brass

Cci400

22.5 grains of h335

Hornady 75grn bthp @2.2500 Hornady 80gr match @ 2.4745

75s are running about 2780

80s at at 2600

The 80s are single load only, not a chance they are going in a mag.I just started loading for the 80s so I haven't tried going up yet, but they shot well in my last highpower match. They are currently about 10 thou from the lands

Hows the brass look? I've never used h33520" white oak barrel

.223 chamber

Lake city brass

Cci400

22.5 grains of h335

Hornady 75grn bthp @2.2500 Hornady 80gr match @ 2.4745

75s are running about 2780

80s at at 2600

The 80s are single load only, not a chance they are going in a mag.I just started loading for the 80s so I haven't tried going up yet, but they shot well in my last highpower match. They are currently about 10 thou from the lands

H335 is a good ball powder. It was the hot ticket in the 90s, but these days it takes a backseat to the stick powders like Varget, 8208XBR, and N140.Hows the brass look? I've never used h335

Starline 5.56 brass, 26.0 StaBALL Match, Rem 7 1/2, and 80 ELDM’s have been very accurate in my 18” Bartlein. 2.500 OAL. Going just over 2800, it has worked well out to 860 yards so far.Thanks. I tested 26.5gr in LC233 brass with the 77TMK at 2.475in just for a quick pressure test to see if my burn rate matched my modified quick load data and I got 2990fps on my Garmin X1 which is about 75fps faster than 24.3 varget in the same 26in IBI barrel.

Looking to get 2800-2850 out my next barrel in 20in.

I have some Starline 556 and LC556 brass on the way. Planning to run 25.8 with the 80.5 and 26.3 with the 77tmk.

According to QL, It’s a tad faster burning than varget and a slightly better burn in the 16-20in barrel and isn’t temp sensitive like TAC.

2800-2850 should be easy for you with a 20” barrel.

Brass looks fine. Honestly I could come up a decent amount to make them hotter.Hows the brass look? I've never used h335

Ok, so the plan from the beginning is to run 75 ELD-M’s in Hornady brass using N540 to run tac class. Barrel maker convinced me to run a longer throat, .110 on the off chance that I want to run 80’s or longer. My concern is I did my first test at 2.500” which put it nearly .093 off the lands. I was able to massage my MDT magazines to get them to load out to 2.520. My question is, is my throat too long and the jump to the lands too high? Is that a thing? Would I be better off loading to my new max magazine length of 2.52? I see a lot of people loading the 75’s just under 2.5.

Ok, so the plan from the beginning is to run 75 ELD-M’s in Hornady brass using N540 to run tac class. Barrel maker convinced me to run a longer throat, .110 on the off chance that I want to run 80’s or longer. My concern is I did my first test at 2.500” which put it nearly .093 off the lands. I was able to massage my MDT magazines to get them to load out to 2.520. My question is, is my throat too long and the jump to the lands too high? Is that a thing? Would I be better off loading to my new max magazine length of 2.52? I see a lot of people loading the 75’s just under 2.5.

Luckily for you the 75 ELDs don’t mind a jump but you should have had it chambered for what you plan on shooting and not what you might shoot. You can’t shoot 80s in Tac.

Just work up a load at 2.500” and run it. You don’t want to be too close to the mag and possibly cause feed issues. The people running under 2.5” are probably running Wylde chambers at .62 freebore. That’s how I have mine set up and I think I am at 2.470” if I remember correctly.

Most people put too much emphasis on running close to the lands. By far the majority of bullets function quite satisfactory with even relatively large jumps.

I would even suggest that for time sensitive competitions and hunting, a large jump might be beneficial. It is quite frustrating when you open the bolt on an unfired round and the bullet stays behind.

I would even suggest that for time sensitive competitions and hunting, a large jump might be beneficial. It is quite frustrating when you open the bolt on an unfired round and the bullet stays behind.

Everyone's chamber is a little different, but you should be fine at that distance. I run the 75 ELD at 2.405 COAL with 8208XBR and that is around .020 off the lands from what I remember. Let us know the N540 load when you get it dialed in.Ok, so the plan from the beginning is to run 75 ELD-M’s in Hornady brass using N540 to run tac class. Barrel maker convinced me to run a longer throat, .110 on the off chance that I want to run 80’s or longer. My concern is I did my first test at 2.500” which put it nearly .093 off the lands. I was able to massage my MDT magazines to get them to load out to 2.520. My question is, is my throat too long and the jump to the lands too high? Is that a thing? Would I be better off loading to my new max magazine length of 2.52? I see a lot of people loading the 75’s just under 2.5.

I'm running 24.9 N540 with the 80 ELD-M, CCI 450, LC brass, 2.500 COAL.

Most people put too much emphasis on running close to the lands. By far the majority of bullets function quite satisfactory with even relatively large jumps.

I would even suggest that for time sensitive competitions and hunting, a large jump might be beneficial. It is quite frustrating when you open the bolt on an unfired round and the bullet stays behind.

That won’t happen with a Wylde chamber. You don’t need a large jump to not have bullets pulled from the case. I have run about .020” on everything and never had that happen in over 20 years of running matches.

Update on the long freebore. Managed to find a load that works well. Running some pissin hot loads at 2970fps out of a 26” bolt action. Definitely a compressed load. Will load some more and maybe seat deeper as it was giving me better groupings. No excuses but I’m pretty sure the 3 fliers are people moving around on the public shooting range bench and knocking my gun around.

25.2gr N540

Hornady brass

FGGM 205M

75 ELD-M

2.480

12FPS SD.

25.2gr N540

Hornady brass

FGGM 205M

75 ELD-M

2.480

12FPS SD.

Attachments

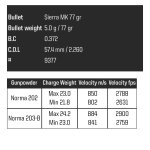

Screwing around with 85.5 Hybrids in a new 223 bolt gun build with .183 free bore, 29.5” Proof competition 7 twist.

Lapua, 205M 24.4 H4895 .015 off

COAL 2.575

CBTO 2.034

2909 AV ES 40 SD 13.4

These are the 50th thru 55th shot on this barrel. Needs more break in….ES sucks

Tried some 90VLDs (right) but they were really underwhelming at this point.

Had success with the 85.5 Hybrids going 2950ish in my 6.5 twist 224V bolt gun.

Trying something stupid and futile for Range 4 Quantico.

Last edited:

Was able to finally settle on a good enough load. Would’ve never thought that seating these further from the lands would have yielded a better grouping. was definitely starting to crunch a little but from what I’ve read that’s ok with 223. Will be perfect at a club match that goes to 600. And if I’m feeling frisky maybe 1000. Did manage to get a steering depth of 2.465 to give an SD of 10 but the groups started opening up and the face of the brass was starting to leave ejector marks. Seated as far down as 2.460 and the SD opened up to 20 and definite signs of over pressure.

26” Straight Jacket Armory

Hornady Brass

75ELDM

205M GMM primer

25.2gr N540

2.2470 COAL

2970fps

12SD

26” Straight Jacket Armory

Hornady Brass

75ELDM

205M GMM primer

25.2gr N540

2.2470 COAL

2970fps

12SD

Attachments

Last edited:

Nicely done.Was able to finally settle on a good enough load. Would’ve never thought that seating these further from the lands would have yielded a better grouping. was definitely starting to crunch a little but from what I’ve read that’s ok with 223. Will be perfect at a club match that goes to 600. And if I’m feeling frisky maybe 1000. Did manage to get a steering depth of 2.465 to give an SD of 10 but the groups started opening up and the face of the brass was starting to leave ejector marks. Seated as far down as 2.460 and the SD opened up to 20 and definite signs of over pressure.

26” Straight Jacket Armory

Hornady Brass

75ELDM

205M GMM primer

25.2gr N540

2.2470 COAL

2970fps

12SD

The 75 ELD @ 2970 will get to 1000, no sweat.

The AB app says 980 when is starts to transition. So we’ll seeNicely done.

The 75 ELD @ 2970 will get to 1000, no sweat.

Similar threads

- Replies

- 3

- Views

- 301

- Replies

- 4

- Views

- 1K

- Replies

- 6

- Views

- 488