Re: "Sandman" 243 stock fitting

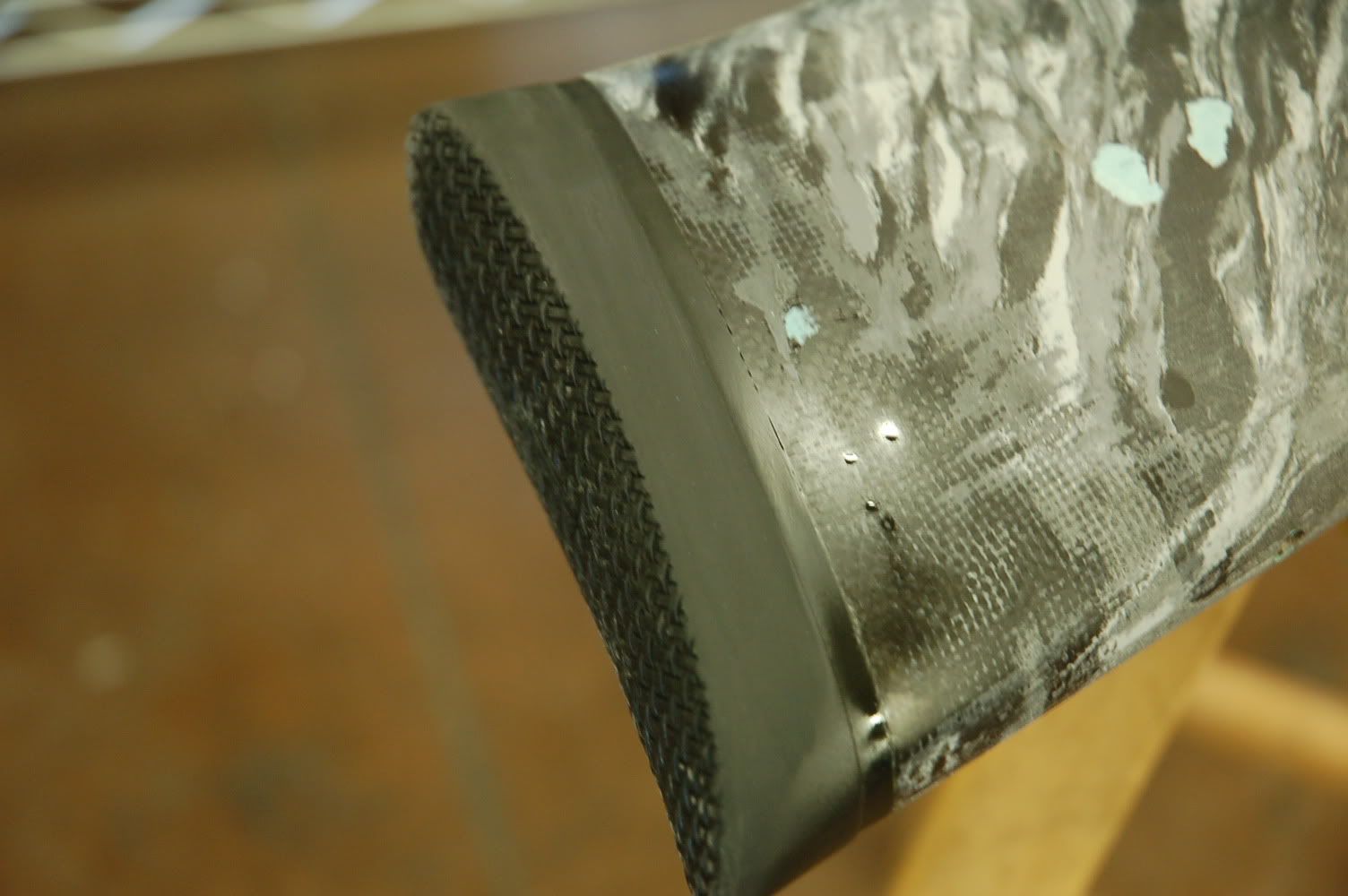

Weather today is suckin pretty bad (rain/sleet/snow) so I figured I'd wrap this up with the flush cup installation.

I wait until after we've painted the stock for this kind of stuff. Masking them off nice and clean is near impossible, so this is the easier route. Just have to be "jonny on the spot" with everything so that were not painting the stock over again.

So begins the fun:

I start with inverting the stock and leveling off the bottom side.

From here I stick a drill chuck in the machine with a wiggler. Measure back 2.5" from the end of the stock and center off the barrel channel by moving to the end and "eyeballing" center based on the radius. So long as my eyeballs aren't crooked today I should be able to hold +/- .005" pretty easily.

Then we bore the hole. In this case a 1/2" x 1/2" deep. It won't leave much left so I'll likely install a big washer of some sort up front inside the channel to prevent a pullout down the road. Stud/flush cups see a hard life so the more solid the better I think.

I use a 1/2" finish em for this task. So long as you don't go bezerk it'll chew through pretty easy. Endmills as a std practice don't really like drilling operations. Tough for the face of the tool to evacuate the chips with any efficiency. Thankfully stock filler is pretty forgiving. To set the depth I just use the quill stop on the manual mill. Stuff the cup between the stop and the veneer for the depth and subtact .04" so it just sits proud of the material. This way the swivel insert doesn't "ring" the paint.

Invert and counterbore for the "washer" I'll make here in a minute.

Now its off to the lathe. I grabbed the first chunk of material that'd work. 303 stainless. Won't ever rust and plenty strong for the screw. Turn it to 5/8" minus a little for clearance, drill/tap for 10-32 and part it off. Forgot to grab the camera so you'll have to imagine it. Nothing special. Just a washer with a threaded hole down the middle.

Onto the "overkill" for this little project. While deployed in the middle east I stumbled upon a BrownSharp MicroMotion hydraulic surface grinder on Ebay. I bought it sight unseen and had it shipped home while still deployed. Recently I got it working. The hydraulics were all screwed up and replacing all the gaskets/seals was going to run well into the $3,000 range.

Phuk that!

I bought a couple O ring kits from a parts house and made my own gaskets out of manilla folders.

Runs like a champ. Aside from a finish pass on the chuck to clean it up and a few experiements with factory M700 recoil lugs I've not had a reason to use it. This is the first "official" job for the machine. Parting off the washer left a bur at the edge of the thread. I decided to grind it clean. 303SS is non magnetic so a couple parallels were pinched against the part to hold it. So long as I don't go crazy it should work fine.

Here's the finished piece:

With that done, it's onto the rear cup, final assembly, and we'll deliver tomorrow.