Re: Bedding with an aluminum bedding block

Keith,

There's fundemental differences between how we do it verses how a production stock company inlets a stock.

Lets define a few things first:

1: Just because something is CNC machined it doesn't mean its magically going to solve all the worlds problems. You can write a very simple program to inlet for a Remington using less than 4 tools and a few lines of code. Or you can write one tens of thousands of blocks long and use many tools.

Either way, it's how well you apply fundamentals and how accurately you machine the part that determines the final outcome.

Form tools: A form tool removes material to shape a part in one pass. An example would be lets say you want to buzz a stock to fit a Remington 700 action. You'd have a 1.350 diameter ball or lollypop endmill ground. You'd likely rough most the material from the center out with a 1" ball or flat EM and finish with the 1.350" od form tool.

Assuming you can fixture the part well enough to tolerate that much tool loading there's nothing wrong with doing it this way. Assuming (as you eluded to) that the receiver is of a consistent diameter from stem/stern.

Surface machining. I draw the part 3 dimensionally. I measure at various points to obtain a (hopefully) accurate representation of the part. Taking into account things like tang geometry, screw locations, taper, etc.

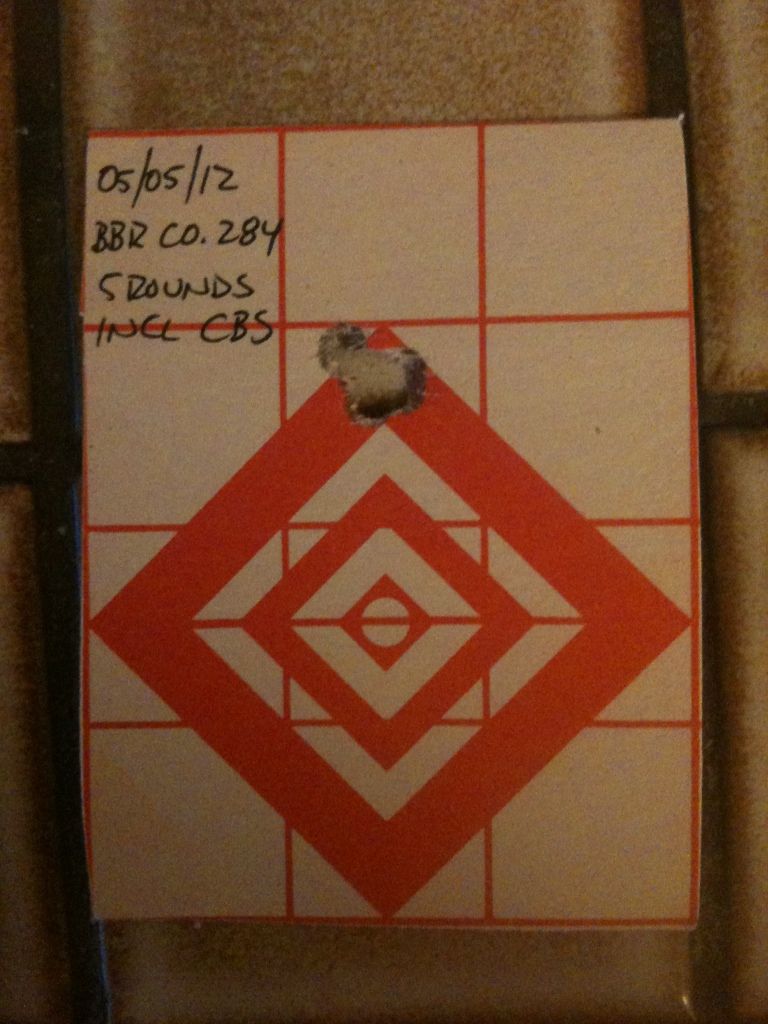

Once the surface is generated a tool much smaller than the radius of the part begins to define all the features. In my case its done with a .1875" ball endmill. With each lap around the part (using a scallop surfacing tool path definition) my stepover was .03". Meaning the tool moves incrementally .03" as it runs through the code.

Principle differences:

No assumptions are made on the part dimensioning

Inside corner features like up in a lug area and back at the tang remain well defined and mirror the part going into them. There's no "dog bone" virtual corner reliefs or tang geometry that's flat on the bottom.

What does it all mean?

One and most important is its more accurate. This isn't new or cutting edge. It's how things like turbine blades, molds, cylinder head ports, and any other part containing complex geometry gets made. By comparison, surface machining a receiver and barrel channel is rather "infant". It's really pretty simple stuff.

As you also mentioned, there are a plethora of rifles out there shooting exceptionally well that defy what is (was) considered cast in stone doctrine a relatively short time ago. So, just how important is it?

In practice probably very little.

In practice a fancy 4 color paint job doesn't mean much either unless your life depends on it, yet there's a long line of folks with $ in their hands willing to pay for it.

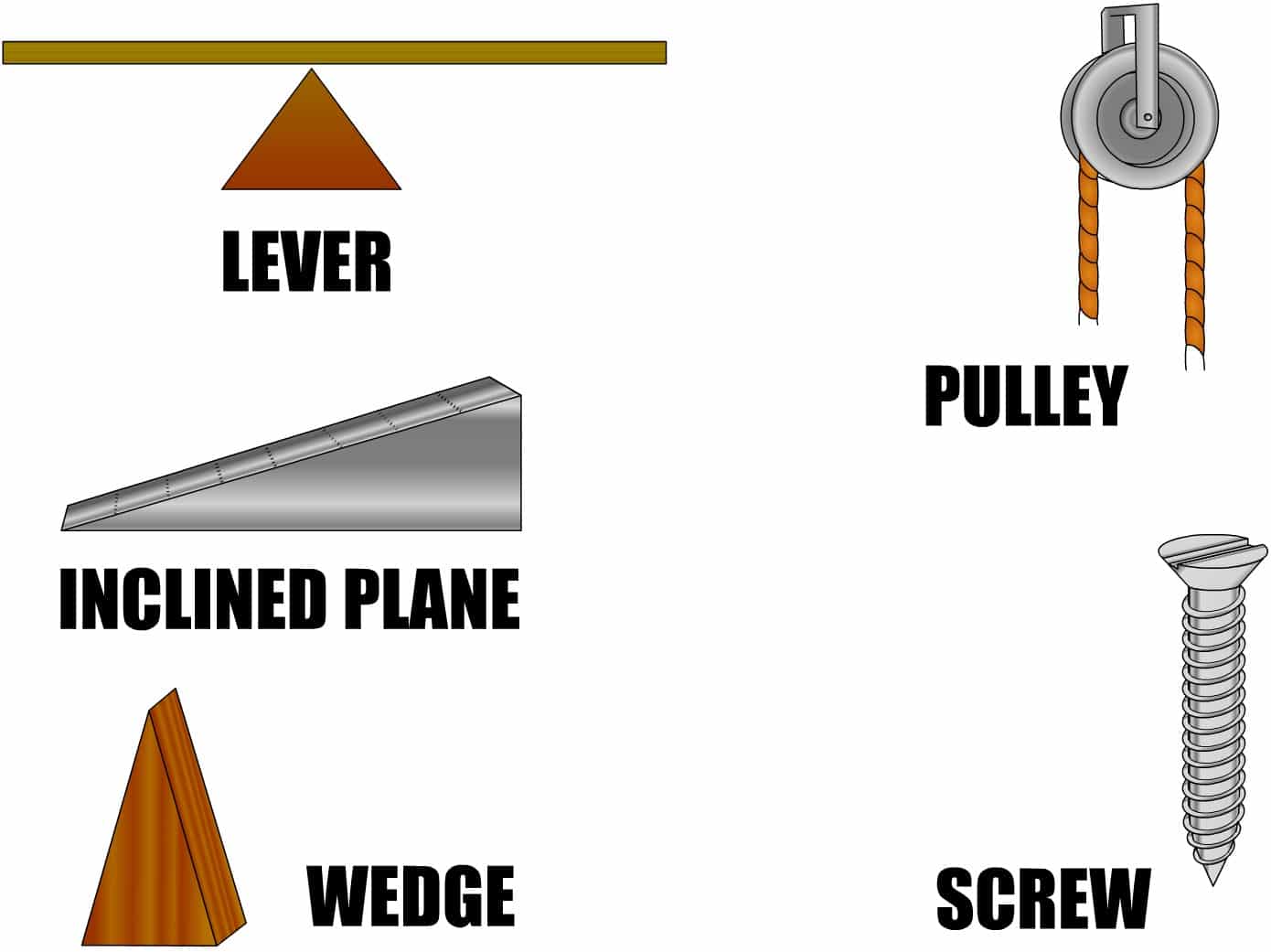

My entire point in sharing this was to offer an alternative method to fitting a receiver to an alloy chassis type stock. As I stated earlier, it seems rather counter productive in my eyes to offer a chassis stock as the "final solution" only to hear of everyone bedding the rear screw because the "wedge" geometry so popular by so many manufacturers doesn't work with a Remington style tang.

To make it work as is without bedding requires relocating the rear guard screw to the same location where the receiver makes tangent contact on both sides of the chassis. Doesn't take a genius to figure out that this isn't a practical or viable solution.

So, bed it and roll or resurface it to something that does work.

I personally strongly disagree with bedding chassis stocks for a number of fundamental reasons. Mostly, resins don't want to adhere to aluminum due to oxidation. Not the way they are supposed to anyway. It's a challenge the aerospace industry struggles with often. It's why I'll never build a gun with AL pillars and why I make my own.

2nd is composites and Aluminum are polar opposites on the galvanic table. Meaning that if you have the two in close proximity and introduce an electrolyte such as salt water, you just made a crude battery. Make it big enough and really bad stuff happens.

The dual carbon hull, AL honey comb America's Cup Yacht being a convenient example. They poked a hole in the outer hull once and as seawater entered the boat began to dissolve itself.

The average rifle will likely never experience this -Till it goes in the ocean or along a coastal beachhead in search of terrorists or Kodiak bears. . .

Contrary to what some may think, there's a reason why I do stuff the way I do. Might not make sense to some, but it makes sense to me and enough other folks that I get to keep doing this week after week.

If I was building a personal rifle for the apocalypse and elected to go the chassis route, I'd do exactly what I did with this H/S stock. Bedding resin would never be used.

Machine it to fit from the beginning and there's no need to.

Last. Just how bad is the average Remington? To check it requires some capital investment in metrology equipment. Bare essentials like a surface plate, height stand, etc are needed.

Unless someone went blazing through the receiver with a felt wheel to polish it for bluing you might just be surprised how consistent the OD is in terms of taper, bellmouth, barrel, etc.

Does it compare to something like a Nesika, Borden, or Defiance? For what it is, it's impressive, but ultimately no. Remington doesn't cylindrically grind the OD of their receivers. I mean, they are made on CNC machines right?

Hope this helped.

C.