Shooters,

Here are two quick videos of myself timing the curvature of the bore on two different barrels.

The first barrel is a Schneider M40. The barrel has about .075" of runout on the muzzle end with the chamber end dialed in correctly. This barrel still shoots extremely well, however it has a slight curve to the bore.

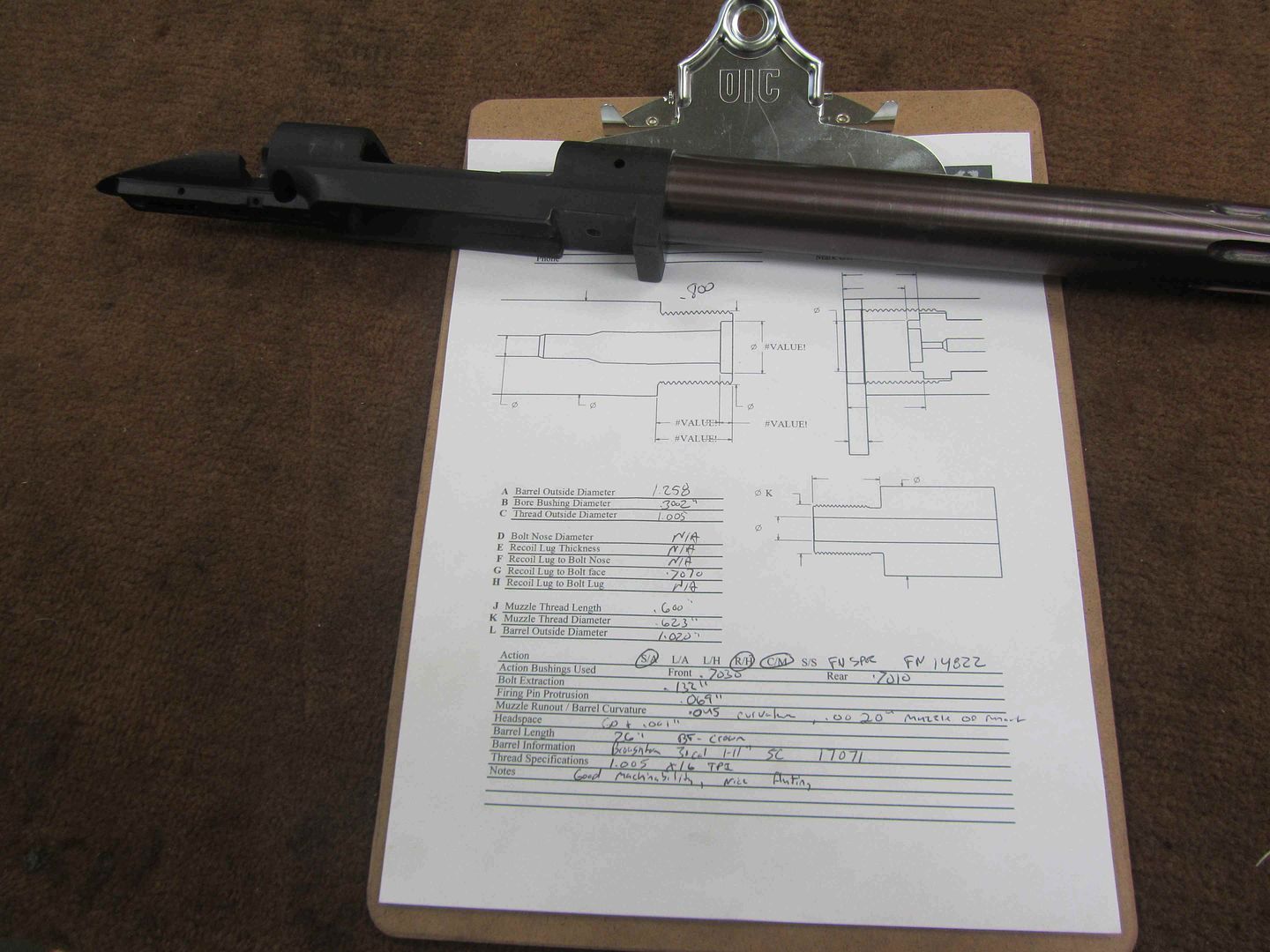

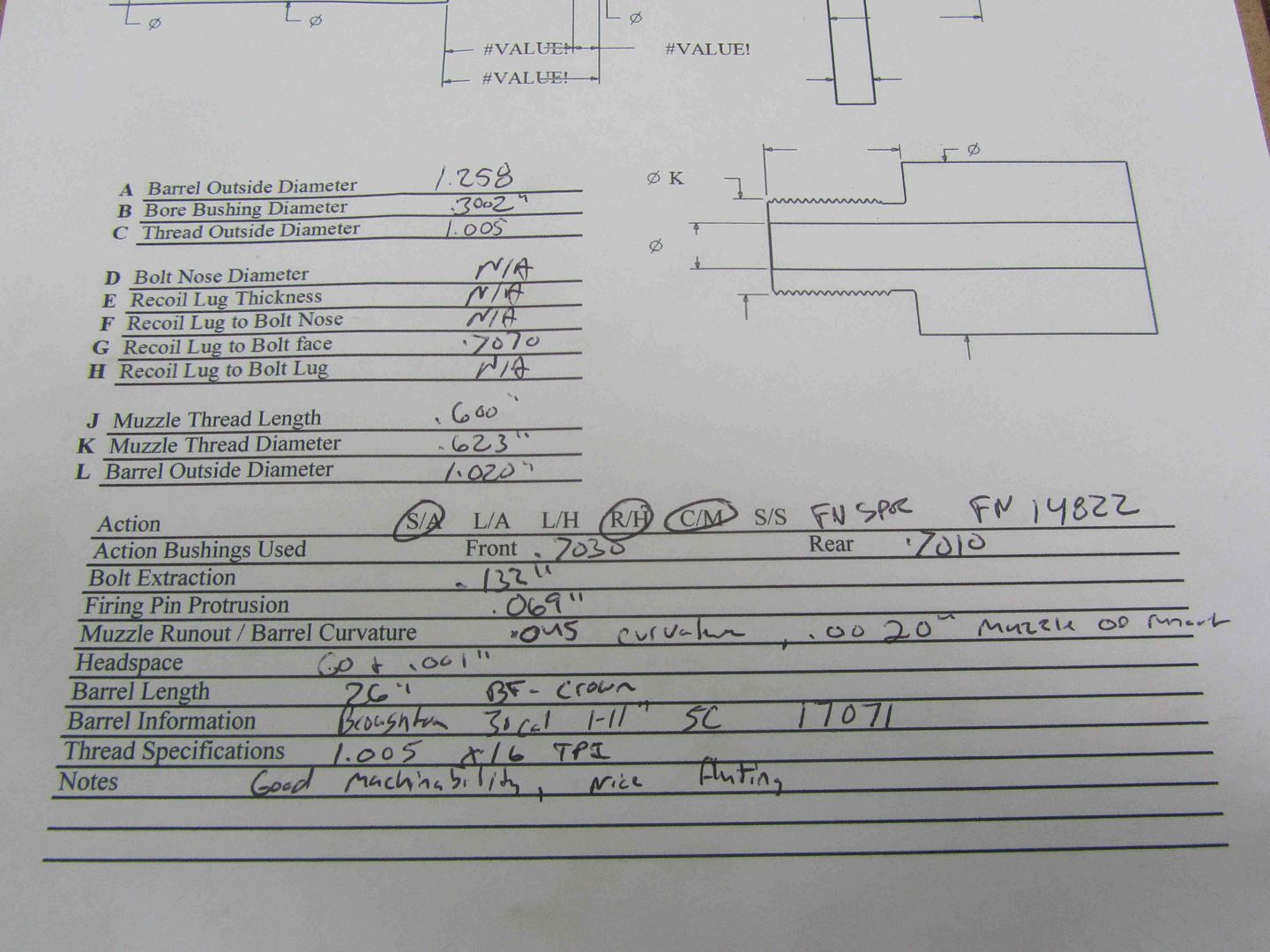

The second barrel is a Bartlein M40 30 cal barrel. This one measures around .015" of muzzle runout. This barrel is extremely straight, most that we barrel up have a .020" - 050" muzzle runout.

Muzzle runout has nothing to do with accuracy, and we have had barrels with around .200" of muzzle runout that still shot extremely well. We like straight barrels however.

Locating the curvature of the bore

Locating the curavture of the bore on a Barlein M40

Thank you for watching.

Mark

Here are two quick videos of myself timing the curvature of the bore on two different barrels.

The first barrel is a Schneider M40. The barrel has about .075" of runout on the muzzle end with the chamber end dialed in correctly. This barrel still shoots extremely well, however it has a slight curve to the bore.

The second barrel is a Bartlein M40 30 cal barrel. This one measures around .015" of muzzle runout. This barrel is extremely straight, most that we barrel up have a .020" - 050" muzzle runout.

Muzzle runout has nothing to do with accuracy, and we have had barrels with around .200" of muzzle runout that still shot extremely well. We like straight barrels however.

Locating the curvature of the bore

Locating the curavture of the bore on a Barlein M40

Thank you for watching.

Mark