I am looking to purchase crown cutter. I have recently purchase a marlin 308 with a 26" heavy barrel and i am wanting to shorten the barrel and recrown it. Thought this would be the perfect first project since the cost of the gun new was around $300. I have came across a company called accumounts.com that has a target crown setup with all the pilots, cutter, and handle for less than $200. Would like to be able to do it with hand tools as i dont have a lathe. Please share your thoughts and suggestions. Thanks

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Barrel Crown Cutter/ got it cut &crowned

- Thread starter rugerdiggs

- Start date

Re: Barrel Crown Cutter

Anything you put into the barrel has a chance of scratching the barrel. However you are doing this on a factory barrel so it wouldn't really do any damage that I don't doubt is already there from machining marks anyway. I would however first compare the price of having a proper smith do it in a lathe and the price of the tool. I do not utilize any tooling along those lines myself as it is always easier to get my smith a 6 pack and borrow the lathe for an hour.

Anything you put into the barrel has a chance of scratching the barrel. However you are doing this on a factory barrel so it wouldn't really do any damage that I don't doubt is already there from machining marks anyway. I would however first compare the price of having a proper smith do it in a lathe and the price of the tool. I do not utilize any tooling along those lines myself as it is always easier to get my smith a 6 pack and borrow the lathe for an hour.

Re: Barrel Crown Cutter

You might want to check out the tooling at PT&G or Manson. I believe they both make what you are looking for . Just my .002. Good luck with your project.

Regards, Paul

You might want to check out the tooling at PT&G or Manson. I believe they both make what you are looking for . Just my .002. Good luck with your project.

Regards, Paul

Re: Barrel Crown Cutter

Cutting and recrowning a barrel on a lever gun can be a whole 'nother ball of wax. IF you don't have a very short spindle head lathe, you wind up pulling the barrel. If you aren't set up to do lever guns- for instance someone that does loads of bolt rifles- is going to have to tool up and or get creative to get the barrel off.

The Manson type crowning cutter is something I keep on hand specifically for lever guns, pump rifles and things of that nature. The 'scratches' in the bore are completely overstated on anything but the very finest of barrels IMO. The marks are similar to if no less than the marks left by chamber reamer pilots, and within 5 rounds or so, the marks will be gone. The reamer marks in the bore of a common production barrel are WAY deeper than the little silver 'smudges' left in the blueing.

Not sure about this tooling you found, the Manson kit was 'spensive but for what I use it for, it pays for itself quickly. Let us know how it turns out.

Cutting and recrowning a barrel on a lever gun can be a whole 'nother ball of wax. IF you don't have a very short spindle head lathe, you wind up pulling the barrel. If you aren't set up to do lever guns- for instance someone that does loads of bolt rifles- is going to have to tool up and or get creative to get the barrel off.

The Manson type crowning cutter is something I keep on hand specifically for lever guns, pump rifles and things of that nature. The 'scratches' in the bore are completely overstated on anything but the very finest of barrels IMO. The marks are similar to if no less than the marks left by chamber reamer pilots, and within 5 rounds or so, the marks will be gone. The reamer marks in the bore of a common production barrel are WAY deeper than the little silver 'smudges' left in the blueing.

Not sure about this tooling you found, the Manson kit was 'spensive but for what I use it for, it pays for itself quickly. Let us know how it turns out.

Re: Barrel Crown Cutter

My bad. Skimmed and saw Marlin .308 and thought of the Express.

Opinion on crowning tool sticks. Disregard tooling for lever gun barrel removal.

My bad. Skimmed and saw Marlin .308 and thought of the Express.

Opinion on crowning tool sticks. Disregard tooling for lever gun barrel removal.

Re: Barrel Crown Cutter

I guess the real question is how are you going to shorten the barrel without a lathe? If you use a saw how are you going to insure that the face is square and true? If its not square the crown cutter won't cut a sqare crown which is very important. You'd be much better off getting it professionally done or at least done by someone with a lathe to keep things straight. Not sure how you can do it by hand and have it right.

Frank

I guess the real question is how are you going to shorten the barrel without a lathe? If you use a saw how are you going to insure that the face is square and true? If its not square the crown cutter won't cut a sqare crown which is very important. You'd be much better off getting it professionally done or at least done by someone with a lathe to keep things straight. Not sure how you can do it by hand and have it right.

Frank

Re: Barrel Crown Cutter

Sorry i should have said its the X7 bolt gun.

In order to keep it square i am either going to make a bracket to fasten to barrel to keep blade square or remove the barrel and chuck into a good drill press protect the threads and slide a hacksaw blade against the machined surface while barrel spinning at low rpm's.

Sorry i should have said its the X7 bolt gun.

In order to keep it square i am either going to make a bracket to fasten to barrel to keep blade square or remove the barrel and chuck into a good drill press protect the threads and slide a hacksaw blade against the machined surface while barrel spinning at low rpm's.

Re: Barrel Crown Cutter

I did talk to Mr Manson today and i really like his cutter with the interchangable carbide tips and the bushing guide that lock in place, i think i can get the setup for $125+shipping.

I did talk to Mr Manson today and i really like his cutter with the interchangable carbide tips and the bushing guide that lock in place, i think i can get the setup for $125+shipping.

Re: Barrel Crown Cutter

I can appreciate your ambition and inclination to do this work yourself..With that being said, I believe your trying to bite off more than you can chew..If you disassemble the rifle and send a Smith The barrel only I'm sure you can find plenty of guys to chop and crown the barrel properly, for no more than what you want to spend on the crowning tool.

Fyi no mater how you hold including holding the barrel in a drill press, you will not end with a straight and true cut

I can appreciate your ambition and inclination to do this work yourself..With that being said, I believe your trying to bite off more than you can chew..If you disassemble the rifle and send a Smith The barrel only I'm sure you can find plenty of guys to chop and crown the barrel properly, for no more than what you want to spend on the crowning tool.

Fyi no mater how you hold including holding the barrel in a drill press, you will not end with a straight and true cut

Re: Barrel Crown Cutter

I also talked to Dave Manson about the 90 degree cutter to true the cut up before crowning it. It may be more than i can do right thats why i wanted to start with a $300 gun that i can rebarrel pretty cheap.

I also talked to Dave Manson about the 90 degree cutter to true the cut up before crowning it. It may be more than i can do right thats why i wanted to start with a $300 gun that i can rebarrel pretty cheap.

Re: Barrel Crown Cutter

Most of us with machines have started with drill presses or other assorted smaller tools first. I can tell you from experience that using a hacksaw or its blade will not get you a square cut. Have a chat with Dave Manson about how you're doing this project and ask him if he thinks the crowning tool will work. He is a very good machinest and knows his stuff. He's helped me out a lot with advice on reamers and can help you as well.

I do applaud your desire to do it yourself as most of us started out that way as well. However, there are times when you should use a pro and here are some reasons:

Carbide does not like to be loaded because its not very strong. If the surface you are cutting is not square and true you will have point loads on the carbide cutter and it will chip and break. This is one reason carbide tooling needs to be spun faster than high speed steel. It keeps the load down on individual portions of the cutter. It would be a shame to spend $125 for the cutting tools only to chip the cutter and end up with a poor crown.

Next is hacksaws. I occasionally use a hacksaw when cutting off parts on my lathe. I find that even if I pre-groove a slot to cut in the blade won't necessarily cut nice and true. Its not in the nature of the tool. While you may get a good cut to your eyes perspective remember that you're trying to make a very exact cut and the eye can't see little things that can make a big difference. Using a guide seems like a great idea at first but when you find that the blade itself flexes enough to make your groove wobbly and 20 thou wider than it should be you will discover that you're once again in the poop. If you try to use the blade without moving it as in just setting it against the barrel and letting a small number of teeth cut, you will find that the teeth quickly wear out, dull and wander more than before. If you move the blade back and forth like a hacksaw is meant to be you will have to let it be free enough to slide and doing that means its free enough to wander.

Last thing is the cost. If you're willing to spend $125 for just the crowning tool set why not spend half that to get the thing done professionally. You should be able to get someone to do it for that. Or better yet, start saving up some cash for the tools you really want like a small lathe. I've seen some pretty good used machines out there for $1000 or less. Keep your eyes peeled. Once you've got a machine of your own you'll be very happy doing all sorts of stuff.

Frank

Most of us with machines have started with drill presses or other assorted smaller tools first. I can tell you from experience that using a hacksaw or its blade will not get you a square cut. Have a chat with Dave Manson about how you're doing this project and ask him if he thinks the crowning tool will work. He is a very good machinest and knows his stuff. He's helped me out a lot with advice on reamers and can help you as well.

I do applaud your desire to do it yourself as most of us started out that way as well. However, there are times when you should use a pro and here are some reasons:

Carbide does not like to be loaded because its not very strong. If the surface you are cutting is not square and true you will have point loads on the carbide cutter and it will chip and break. This is one reason carbide tooling needs to be spun faster than high speed steel. It keeps the load down on individual portions of the cutter. It would be a shame to spend $125 for the cutting tools only to chip the cutter and end up with a poor crown.

Next is hacksaws. I occasionally use a hacksaw when cutting off parts on my lathe. I find that even if I pre-groove a slot to cut in the blade won't necessarily cut nice and true. Its not in the nature of the tool. While you may get a good cut to your eyes perspective remember that you're trying to make a very exact cut and the eye can't see little things that can make a big difference. Using a guide seems like a great idea at first but when you find that the blade itself flexes enough to make your groove wobbly and 20 thou wider than it should be you will discover that you're once again in the poop. If you try to use the blade without moving it as in just setting it against the barrel and letting a small number of teeth cut, you will find that the teeth quickly wear out, dull and wander more than before. If you move the blade back and forth like a hacksaw is meant to be you will have to let it be free enough to slide and doing that means its free enough to wander.

Last thing is the cost. If you're willing to spend $125 for just the crowning tool set why not spend half that to get the thing done professionally. You should be able to get someone to do it for that. Or better yet, start saving up some cash for the tools you really want like a small lathe. I've seen some pretty good used machines out there for $1000 or less. Keep your eyes peeled. Once you've got a machine of your own you'll be very happy doing all sorts of stuff.

Frank

Re: Barrel Crown Cutter

For a new rifle, I'd have it professionally done.

But being a DIY guy, on my Mosin Nagant project I broke out the hacksaw- chopped it to 22", and used a Brownell's 11-degree cutter with a .311 pilot.

The hacksaw cut was way out of square. But with a tight pilot, the cutter will lie at ninety degrees, make contact initially at the "high" points, and square the muzzle first, then begin actually cutting the recessed crown.

I'd never do it on a precision rifle barrel- but I can tell you that when completed (with a lot more work than than just the barrel) it shoots sub-minute with handloads, and I shoot it regularly at 600 yards.

For a new rifle, I'd have it professionally done.

But being a DIY guy, on my Mosin Nagant project I broke out the hacksaw- chopped it to 22", and used a Brownell's 11-degree cutter with a .311 pilot.

The hacksaw cut was way out of square. But with a tight pilot, the cutter will lie at ninety degrees, make contact initially at the "high" points, and square the muzzle first, then begin actually cutting the recessed crown.

I'd never do it on a precision rifle barrel- but I can tell you that when completed (with a lot more work than than just the barrel) it shoots sub-minute with handloads, and I shoot it regularly at 600 yards.

Re: Barrel Crown Cutter

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: rugerdiggs</div><div class="ubbcode-body">I am looking to purchase crown cutter. I have recently purchase a marlin 308 with a 26" heavy barrel and i am wanting to shorten the barrel and recrown it. Thought this would be the perfect first project since the cost of the gun new was around $300. I have came across a company called accumounts.com that has a target crown setup with all the pilots, cutter, and handle for less than $200. Would like to be able to do it with hand tools as i dont have a lathe. Please share your thoughts and suggestions. Thanks </div></div>

Sandvik CXS series solid carbide boring bars are what we use to single point all of our crowns.

So far so good. (10+ years at it)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: rugerdiggs</div><div class="ubbcode-body">I am looking to purchase crown cutter. I have recently purchase a marlin 308 with a 26" heavy barrel and i am wanting to shorten the barrel and recrown it. Thought this would be the perfect first project since the cost of the gun new was around $300. I have came across a company called accumounts.com that has a target crown setup with all the pilots, cutter, and handle for less than $200. Would like to be able to do it with hand tools as i dont have a lathe. Please share your thoughts and suggestions. Thanks </div></div>

Sandvik CXS series solid carbide boring bars are what we use to single point all of our crowns.

So far so good. (10+ years at it)

Re: Barrel Crown Cutter

My smith told me to find a ball bearing 1/10th of an inch larger than the bore and some lapping compound, and cut the crown myself. It took about 30 mins. This 16" chromoly AR15 barrel went from 3 moa to 1 moa.

My smith told me to find a ball bearing 1/10th of an inch larger than the bore and some lapping compound, and cut the crown myself. It took about 30 mins. This 16" chromoly AR15 barrel went from 3 moa to 1 moa.

Re: Barrel Crown Cutter

I used a hacksaw to cut the barrel down on my tikka... Evened it up with a file, then a sander, then after polishing I used several brass screws with lapping compound.

Gun shoots clover leaf groups still, so that's good enough for me. When I rebarrel it'll get sent to a real smith though.

I used a hacksaw to cut the barrel down on my tikka... Evened it up with a file, then a sander, then after polishing I used several brass screws with lapping compound.

Gun shoots clover leaf groups still, so that's good enough for me. When I rebarrel it'll get sent to a real smith though.

Re: Barrel Crown Cutter

Well i spoke to Dave Manson again this morning and i have a crown cutter coming, will update my results as it goes good or bad, hope all good lol

Well i spoke to Dave Manson again this morning and i have a crown cutter coming, will update my results as it goes good or bad, hope all good lol

Re: Barrel Crown Cutter

Easy-peasy...

Plug the barrel with a patch, and be sure to use plenty of cutting oil. Go slow and let the cutter do the work.

Let us know how it goes, post a pic of the finished job.

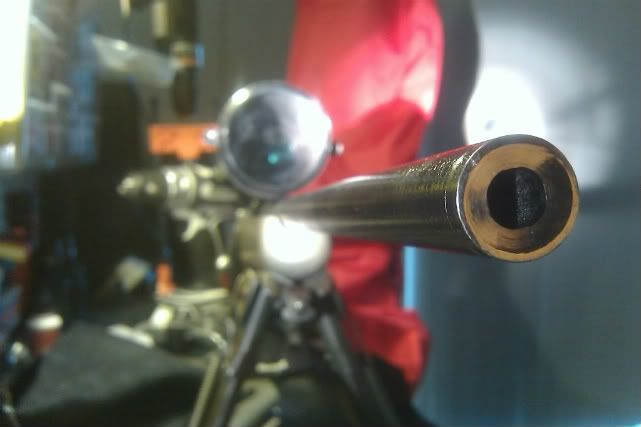

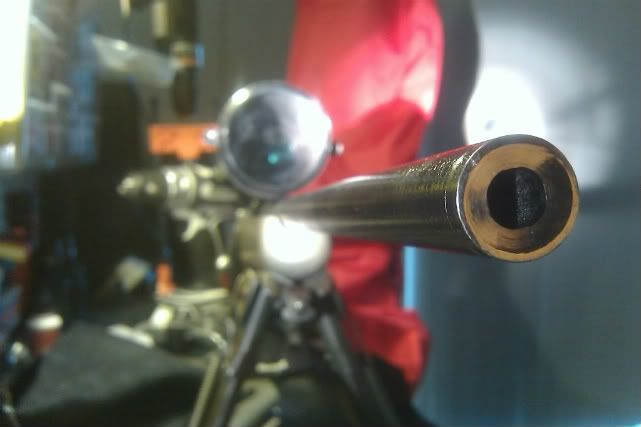

My results from the PTG 11-degree cutter:

Easy-peasy...

Plug the barrel with a patch, and be sure to use plenty of cutting oil. Go slow and let the cutter do the work.

Let us know how it goes, post a pic of the finished job.

My results from the PTG 11-degree cutter:

Re: Barrel Crown Cutter

Well i got my manson cutter in and going to attempt this tonight or friday, another quick question please. I got some fine steel wool to use and or a couple of round wood screws with wooden dial rod and some lapping compound to hand lap, whats yalls thoughts on lapping this?

Well i got my manson cutter in and going to attempt this tonight or friday, another quick question please. I got some fine steel wool to use and or a couple of round wood screws with wooden dial rod and some lapping compound to hand lap, whats yalls thoughts on lapping this?

Re: Barrel Crown Cutter

Sucky part was after got it done and cleaning up noticed front screw on mount broke in action, with lots of luck, very small screwdriver and hammer got it out though

Sucky part was after got it done and cleaning up noticed front screw on mount broke in action, with lots of luck, very small screwdriver and hammer got it out though

Re: Barrel Crown Cutter

I'm surprised you got it to cut that flat starting with a hacksaw. I thought you would end up with some waves that would be hard to get out once they started. Good job.

I had an old set of crown cutters that I was going to give you when I first read this thread, but couldn't locate them. It only had a flat and 60 degree cutter anyway so they were pretty much worthless. I bought them a long time ago when a good client said he had an old lever gun he wanted me to crown... turned out to be an '86 Winchester. Needless to say that they were never used.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: rugerdiggs</div><div class="ubbcode-body">My finished product, please tell me what you think.

</div></div>

</div></div>

I'm surprised you got it to cut that flat starting with a hacksaw. I thought you would end up with some waves that would be hard to get out once they started. Good job.

I had an old set of crown cutters that I was going to give you when I first read this thread, but couldn't locate them. It only had a flat and 60 degree cutter anyway so they were pretty much worthless. I bought them a long time ago when a good client said he had an old lever gun he wanted me to crown... turned out to be an '86 Winchester. Needless to say that they were never used.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: rugerdiggs</div><div class="ubbcode-body">My finished product, please tell me what you think.

Re: Barrel Crown Cutter

It looks good! I've also used the same tool to re-crown a couple of barrels. Btw, are you going to remove the knife edge after the 11 degree cut? Manson sells the 45 degree chamfer cutter to use with the center pilot.

It looks good! I've also used the same tool to re-crown a couple of barrels. Btw, are you going to remove the knife edge after the 11 degree cut? Manson sells the 45 degree chamfer cutter to use with the center pilot.

Re: Barrel Crown Cutter

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: rugerdiggs</div><div class="ubbcode-body">My finished product, please tell me what you think.

</div></div>

</div></div>

Excellent! Not surprising to me, actually. I've used this crowning method hundreds of times, I've done stainless, alloy steel and chromed lined barrels, rifles, shotguns, revolvers and pistols. I have a complete set, for any caliber from 5.45 mm to 0.50 cal. I still use original carbide blades from 2002. Because of the specifics of carbide blade design, they do not "chip" due to cutting itself, only if cutter is dropped on some hard surface...

If I were to collect even $20 for every crowning job I've done, I would have paid for the complete kit (with 14 pilots, 3 cutters, driver and accessories) many, many times over. Done a bunch of crowns for my buddies, no charge. Takes may be between 3 and 6 minutes on average, per crown.

OP managed to remove a lot of metal by just using 11 degree cutter, probably took him, I estimate, 15-20 minutes, but I do not believe it was hard to do, cause he obviously used power driver.

I always use 0 degree cutter first, then 11 degree, then a chamfering cutter. This is if I do barrel, which was cut by the saw. For re-crowning of already existing crown, 11 degree cutter works plenty fast w/o need to square the barrel off with 0 degree cutter.

The huge advantage of this sytem is the ability to do pretty precise muzzle crown w/o need to disassemble the fiream and remove the barrel for doing it on the lathe. Another serious advantage is the use of none-rotating expandable pilots and serrated carbide blades. It does not require anybody who uses it to be "an expert", just to follow simple instructions. Practically any firearm can be done, in the shop or in the field. BTW, it works great for revolvers, some of which have fancy shaped barrels, which are difficult to mount in a lathe chuck. Manson also offers shotgun barrel cutter, the only hand tool I believe to be suitable for squaring off the muzzle ends of double barrel shotguns.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: rugerdiggs</div><div class="ubbcode-body">My finished product, please tell me what you think.

Excellent! Not surprising to me, actually. I've used this crowning method hundreds of times, I've done stainless, alloy steel and chromed lined barrels, rifles, shotguns, revolvers and pistols. I have a complete set, for any caliber from 5.45 mm to 0.50 cal. I still use original carbide blades from 2002. Because of the specifics of carbide blade design, they do not "chip" due to cutting itself, only if cutter is dropped on some hard surface...

If I were to collect even $20 for every crowning job I've done, I would have paid for the complete kit (with 14 pilots, 3 cutters, driver and accessories) many, many times over. Done a bunch of crowns for my buddies, no charge. Takes may be between 3 and 6 minutes on average, per crown.

OP managed to remove a lot of metal by just using 11 degree cutter, probably took him, I estimate, 15-20 minutes, but I do not believe it was hard to do, cause he obviously used power driver.

I always use 0 degree cutter first, then 11 degree, then a chamfering cutter. This is if I do barrel, which was cut by the saw. For re-crowning of already existing crown, 11 degree cutter works plenty fast w/o need to square the barrel off with 0 degree cutter.

The huge advantage of this sytem is the ability to do pretty precise muzzle crown w/o need to disassemble the fiream and remove the barrel for doing it on the lathe. Another serious advantage is the use of none-rotating expandable pilots and serrated carbide blades. It does not require anybody who uses it to be "an expert", just to follow simple instructions. Practically any firearm can be done, in the shop or in the field. BTW, it works great for revolvers, some of which have fancy shaped barrels, which are difficult to mount in a lathe chuck. Manson also offers shotgun barrel cutter, the only hand tool I believe to be suitable for squaring off the muzzle ends of double barrel shotguns.

Re: Barrel Crown Cutter

3 shots at 85yards with 15mphit left to right wind, not best shooting conditions but had to try it, very happy thus far

3 shots at 85yards with 15mphit left to right wind, not best shooting conditions but had to try it, very happy thus far

Re: Barrel Crown Cutter

Looks great.

I see you took the recessed crown all the way to the edge. I asked about this before doing mine, the consensus seemed to be that it really didn't matter whether it's done that way, or leaving a flat reveal around the edge, as I did in the pic above.

Let us know how it shoots.

Looks great.

I see you took the recessed crown all the way to the edge. I asked about this before doing mine, the consensus seemed to be that it really didn't matter whether it's done that way, or leaving a flat reveal around the edge, as I did in the pic above.

Let us know how it shoots.

Re: Barrel Crown Cutter

Put a tactical bolt knob on it to, bench grinder, lots of patience, cup of cooling water, 5/16x24 die and some cutting oil.

Put a tactical bolt knob on it to, bench grinder, lots of patience, cup of cooling water, 5/16x24 die and some cutting oil.

Re: Barrel Crown Cutter

Good job.

Got any pictures of the "crown print"?

(That's the cool swirly soot pattern you get after firing a few shots on a nice clean crown. Looks really symmetrical when you've got a nice crown)

Good job.

Got any pictures of the "crown print"?

(That's the cool swirly soot pattern you get after firing a few shots on a nice clean crown. Looks really symmetrical when you've got a nice crown)

Re: Barrel Crown Cutter

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">Good job.

Got any pictures of the "crown print"?

(That's the cool swirly soot pattern you get after firing a few shots on a nice clean crown. Looks really symmetrical when you've got a nice crown) </div></div>

Guess I should clarify. This is what a "crown print" looks like, this is not the OP's crown print.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">Good job.

Got any pictures of the "crown print"?

(That's the cool swirly soot pattern you get after firing a few shots on a nice clean crown. Looks really symmetrical when you've got a nice crown) </div></div>

Guess I should clarify. This is what a "crown print" looks like, this is not the OP's crown print.

Re: Barrel Crown Cutter

I have had great success with the Manson crown cutter as has the OP and as I stated above. There are a lot of situations where this thing makes the difference, lever guns, military sporterizations turned bubba, semi auto commercial rifles (BAR/7400) etc.

I do of course spin out crowns in the lather for my higher end projects, but making the ends meet with bubba smith wanting his 742 Custom Floorboard Crown straightened out will pay 40$ bucks or so to get it straightened out as opposed to paying to have the barrel pulled and going through the motions.

Good job to OP, I just picked up one of those exact Marlins for experimental purposes. I can't wait toplay now that I see yours shooting like this.

I have had great success with the Manson crown cutter as has the OP and as I stated above. There are a lot of situations where this thing makes the difference, lever guns, military sporterizations turned bubba, semi auto commercial rifles (BAR/7400) etc.

I do of course spin out crowns in the lather for my higher end projects, but making the ends meet with bubba smith wanting his 742 Custom Floorboard Crown straightened out will pay 40$ bucks or so to get it straightened out as opposed to paying to have the barrel pulled and going through the motions.

Good job to OP, I just picked up one of those exact Marlins for experimental purposes. I can't wait toplay now that I see yours shooting like this.

Re: Barrel Crown Cutter

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: MattK287</div><div class="ubbcode-body">My smith told me to find a ball bearing 1/10th of an inch larger than the bore and some lapping compound, and cut the crown myself. It took about 30 mins. This 16" chromoly AR15 barrel went from 3 moa to 1 moa.</div></div>

I needed to clean up a crown one time years ago and an old time smith told me to go get a brass round head machine screw with some lapping compound and a hand drill. It did work but I think the brass took the brunt of the lapping!

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: MattK287</div><div class="ubbcode-body">My smith told me to find a ball bearing 1/10th of an inch larger than the bore and some lapping compound, and cut the crown myself. It took about 30 mins. This 16" chromoly AR15 barrel went from 3 moa to 1 moa.</div></div>

I needed to clean up a crown one time years ago and an old time smith told me to go get a brass round head machine screw with some lapping compound and a hand drill. It did work but I think the brass took the brunt of the lapping!

Re: Barrel Crown Cutter

I have heard of every conceivable lapping voodoo for crowns over the last 20 years, and have found it in my experience to be less beneficial and potentially damaging.

I have heard of every conceivable lapping voodoo for crowns over the last 20 years, and have found it in my experience to be less beneficial and potentially damaging.

Re: Barrel Crown Cutter

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">Good job.

Got any pictures of the "crown print"?

(That's the cool swirly soot pattern you get after firing a few shots on a nice clean crown. Looks really symmetrical when you've got a nice crown) </div></div>

When i get a chance to shoot it again i will take a couple pics, i cleaned it before putting it away.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">Good job.

Got any pictures of the "crown print"?

(That's the cool swirly soot pattern you get after firing a few shots on a nice clean crown. Looks really symmetrical when you've got a nice crown) </div></div>

When i get a chance to shoot it again i will take a couple pics, i cleaned it before putting it away.

Re: Barrel Crown Cutter

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">Good job.

Got any pictures of the "crown print"?

(That's the cool swirly soot pattern you get after firing a few shots on a nice clean crown. Looks really symmetrical when you've got a nice crown) </div></div>

After I did mine and got it to the range I noticed that, and posted a thread about it because I'd never seen it before...

Who knows...why they look like little phallic symbols(hey- wife, not me.....)

Are you supposed to touch up the new crown with cold blueing? I've been getting surface rust on the crown, buffs out but I'd like to resolve it...

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">Good job.

Got any pictures of the "crown print"?

(That's the cool swirly soot pattern you get after firing a few shots on a nice clean crown. Looks really symmetrical when you've got a nice crown) </div></div>

After I did mine and got it to the range I noticed that, and posted a thread about it because I'd never seen it before...

Who knows...why they look like little phallic symbols(hey- wife, not me.....)

Are you supposed to touch up the new crown with cold blueing? I've been getting surface rust on the crown, buffs out but I'd like to resolve it...

Re: Barrel Crown Cutter

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Gene Poole</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">Good job.

Got any pictures of the "crown print"?

(That's the cool swirly soot pattern you get after firing a few shots on a nice clean crown. Looks really symmetrical when you've got a nice crown) </div></div>

Guess I should clarify. This is what a "crown print" looks like, this is not the OP's crown print.

</div></div>

</div></div>

Is this what a good crown print looks like, guess i havnt thought about it till now but if the crown is uniform the gases should print uniform pic, thanks for bringing up, very green to this but very willing to learn all i can, thanks again

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Gene Poole</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">Good job.

Got any pictures of the "crown print"?

(That's the cool swirly soot pattern you get after firing a few shots on a nice clean crown. Looks really symmetrical when you've got a nice crown) </div></div>

Guess I should clarify. This is what a "crown print" looks like, this is not the OP's crown print.

</div></div>

</div></div>Is this what a good crown print looks like, guess i havnt thought about it till now but if the crown is uniform the gases should print uniform pic, thanks for bringing up, very green to this but very willing to learn all i can, thanks again

Re: Barrel Crown Cutter

I hope to have a lathe in the near future if i can get a reasonable priced one.

I hope to have a lathe in the near future if i can get a reasonable priced one.

Re: Barrel Crown Cutter

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: DevilDog1775</div><div class="ubbcode-body">Great job rugerdiggs!!!,did you refinish the new crown? </div></div>

No i havent, i havnt had it out in the elements yet but still undecided what to put on it, cold blue or krylon or? Had also thought of painting the whole thing with some alumahide or cerakote

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: DevilDog1775</div><div class="ubbcode-body">Great job rugerdiggs!!!,did you refinish the new crown? </div></div>

No i havent, i havnt had it out in the elements yet but still undecided what to put on it, cold blue or krylon or? Had also thought of painting the whole thing with some alumahide or cerakote

Re: Barrel Crown Cutter

Thanks for all the help and compliments, hope to take several more minor jobs on and work my way to the harder stuff.

Wanted ask for thoughts on the outside edge of crown, its still pretty sharp. Dont know if it will hurt to be this way or stand a risk of being chipped?

Thanks for all the help and compliments, hope to take several more minor jobs on and work my way to the harder stuff.

Wanted ask for thoughts on the outside edge of crown, its still pretty sharp. Dont know if it will hurt to be this way or stand a risk of being chipped?

Re: Barrel Crown Cutter

From a owner of a Manson facing and crowning tool I can tell you they do a damn good job when you use the correctly. There are a lot of people that worry about stuff that don't need worried about. Doubt me read some of the post's on the first page. Anyway, nice job to the OP. It is refreshing to see someone that isn't afraid to tackle a job.

From a owner of a Manson facing and crowning tool I can tell you they do a damn good job when you use the correctly. There are a lot of people that worry about stuff that don't need worried about. Doubt me read some of the post's on the first page. Anyway, nice job to the OP. It is refreshing to see someone that isn't afraid to tackle a job.

Re: Barrel Crown Cutter

I use a Brownells 1/2" 120 deg cutter with solid pilots. Makes a nice recessed crown on my target rifles. I use a 5/15" rod coupling, and a nut driver on my Ryobi battery drill, to give some slack to the driver, so I don't force the pilot sideways. Lots of cutting oil, and brush off chips frequently. Did a few friends rifles, I think I undercharged them at $30, but it only takes 1/2 hour....Break the inside edge with some 600 grit and a round head screw in the same batt drill. PS: My 308 Palma rifle crowned this way did clean the 800 and 900 yd line a few times, before my cataract forced me to F class.

I use a Brownells 1/2" 120 deg cutter with solid pilots. Makes a nice recessed crown on my target rifles. I use a 5/15" rod coupling, and a nut driver on my Ryobi battery drill, to give some slack to the driver, so I don't force the pilot sideways. Lots of cutting oil, and brush off chips frequently. Did a few friends rifles, I think I undercharged them at $30, but it only takes 1/2 hour....Break the inside edge with some 600 grit and a round head screw in the same batt drill. PS: My 308 Palma rifle crowned this way did clean the 800 and 900 yd line a few times, before my cataract forced me to F class.

Re: Barrel Crown Cutter

I'm surprised we haven't heard the screaming that a cut/crown job can only be done correctly on a $15K lathe...

I'm surprised we haven't heard the screaming that a cut/crown job can only be done correctly on a $15K lathe...

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 8

- Views

- 540

- Replies

- 15

- Views

- 1K

- Replies

- 41

- Views

- 1K