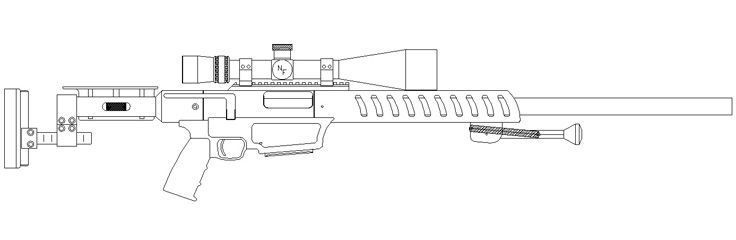

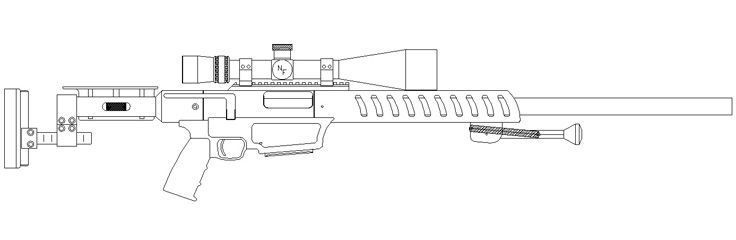

About eight months ago I started on a project to make a tubegun chassis for my Savage actions. I worked on it in my free time after work and some weekends. I started by looking at the few that are available commercially for other actions, and taking the features that I liked, designed my own version on AutoCAD software.

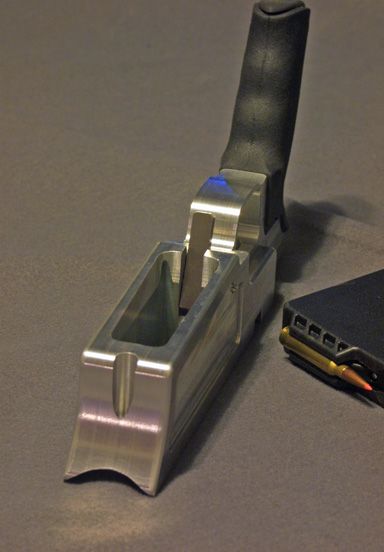

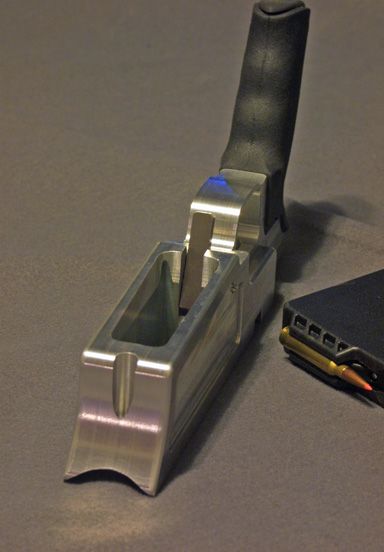

I ordered a piece of 1.5x3inch 6061 stock to make the lower receiver from. I machined a radius in the top of the lower to mate to the 2inch tube. The action screw holes, two locating dowel holes, and the dead center of the mag-well were reamed through the receiver. The action screw holes were opened up near the end of the build for clearance. The lower receiver was clearenced for the trigger assembly, and the mag-well was wire-EDM cut to accept Accuracy International magazines. I bought a five round 308mag, and a ten round 223mag. The opening of the mag-well was beveled just enough to make inserting mags easier.

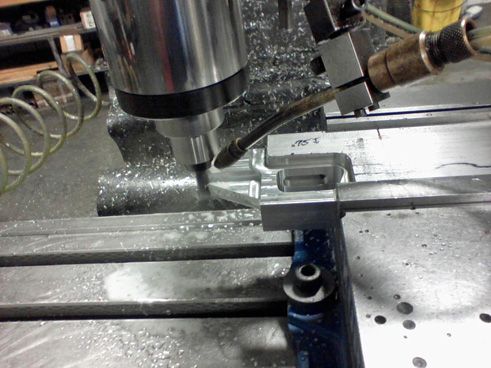

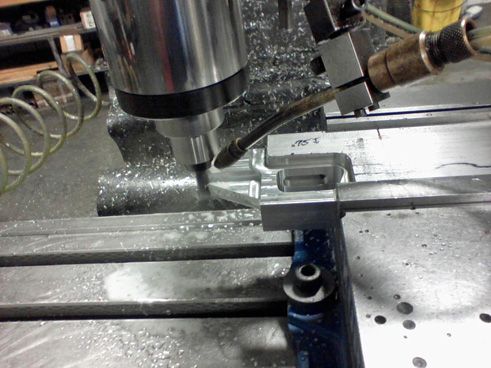

Mag-catch being machined.

The outside profile was machined, and cut to take an AR style grip.

I ordered a piece of 1.5x3inch 6061 stock to make the lower receiver from. I machined a radius in the top of the lower to mate to the 2inch tube. The action screw holes, two locating dowel holes, and the dead center of the mag-well were reamed through the receiver. The action screw holes were opened up near the end of the build for clearance. The lower receiver was clearenced for the trigger assembly, and the mag-well was wire-EDM cut to accept Accuracy International magazines. I bought a five round 308mag, and a ten round 223mag. The opening of the mag-well was beveled just enough to make inserting mags easier.

Mag-catch being machined.

The outside profile was machined, and cut to take an AR style grip.